Precision step and touch voltage calculators are essential tools for electrical safety assessment worldwide best.

Engineers require accurate models, compliance checks, and calculators to reduce hazardous potentials near grounding systems.

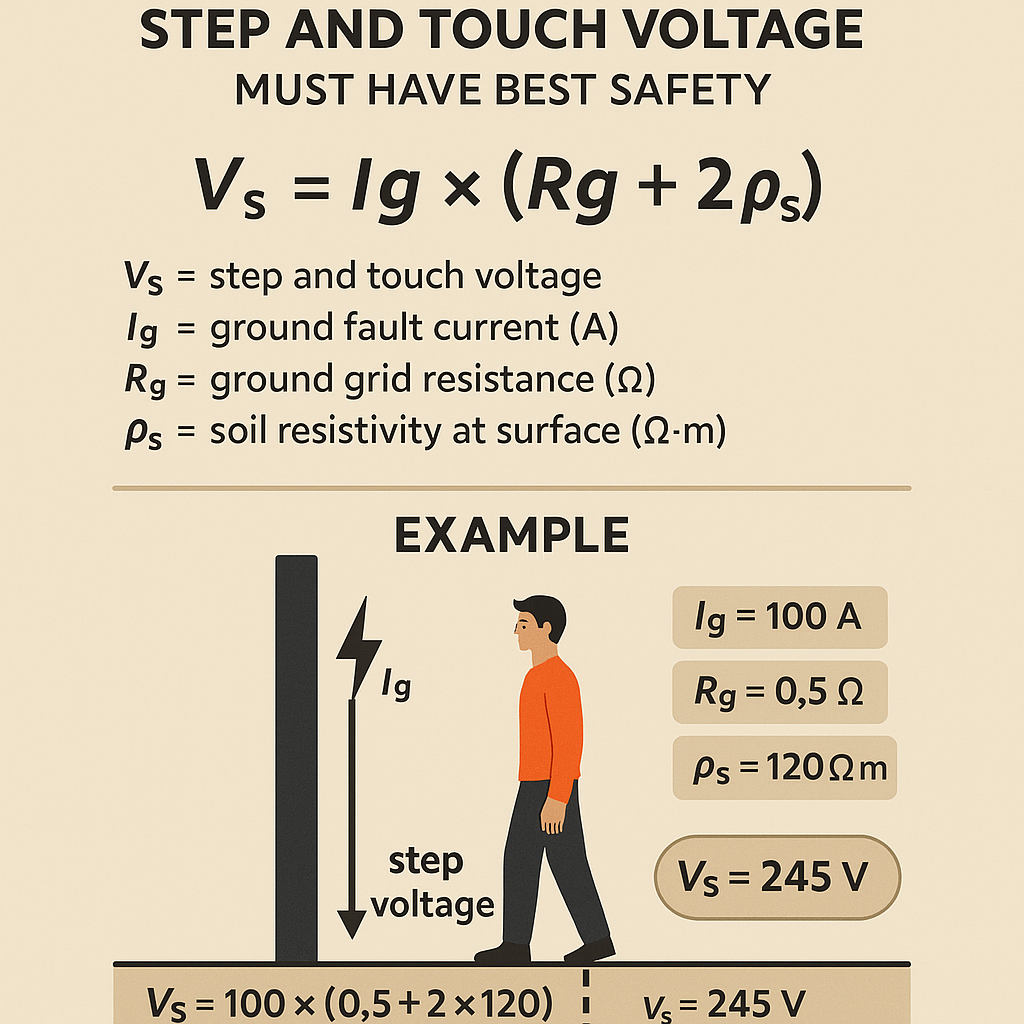

Step and Touch Voltage Calculator — Safety-Oriented Engineering Tool

Purpose and scope of step and touch voltage calculation

Step and touch voltage calculations quantify hazardous potential differences on and near the earth surface during fault conditions. These calculations guide the design and verification of earthing systems for substations, transmission towers, distribution poles, renewable-energy arrays, and industrial plants.

Why calculators are mandatory for safety

- They translate measured soil resistivity and fault current into spatial potential gradients.

- They evaluate compliance with international earthing safety limits and local regulations.

- They enable design optimization of ground grids, mats, electrodes, and bonding to mitigate step/touch hazards.

Fundamental concepts: step voltage, touch voltage, surface potential

Step voltage is the potential difference between two points on the ground surface separated by a nominal step length (often 1 m). Touch voltage is the potential difference between a grounded object (or electrode) and a person contacting that object while standing on the ground surface.

Definitions used by engineers

- Surface potential V(r): the voltage at a location r from the current injection point relative to remote earth.

- Step voltage ΔV_step ≈ |V(r) − V(r + s)|, where s is the step length (commonly 1 m).

- Touch voltage V_touch = |V(object) − V(feet)| when the object is at a different potential than the standing surface.

Essential inputs for any step and touch voltage calculator

- Fault current magnitude and duration (I_fault, t_fault).

- Soil resistivity and layering (ρ1, ρ2, layer thicknesses).

- Electrode geometry: rod length, grid layout, conductor burial depth, ring conductor dimensions.

- Grid mesh size and conductor resistances.

- Equipotential bonding connections and locations of conductive structures.

- Expected human contact scenarios (standing posture, step length, footwear or barefoot).

Soil resistivity measurement formula (Wenner method)

Variables:

- ρ = soil resistivity in ohm·m

- a = electrode spacing in meters (Wenner spacing)

- V = measured voltage between potential electrodes in volts

- I = injected current between current electrodes in amperes

Typical values: for a = 5 m, V/I = 10 Ω, then ρ = 2 * π * 5 * 10 ≈ 314.16 Ω·m.

Analytical approximations and formulas used in calculators

Calculators use a mix of closed-form approximations, image theory, and numerical finite-element/finite-difference models. For quick checks, two common analytical formulas are provided below.

Point source (surface) approximation

Variables:

- V(r) = surface potential at radial distance r (V)

- ρ = uniform soil resistivity (Ω·m)

- I = injected fault current to earth (A)

- r = radial distance from injection point (m)

Typical values example: ρ = 100 Ω·m, I = 10 000 A, r = 1 m gives V(1) ≈ (100*10000)/(2π*1) ≈ 159 155 V.

Notes: This model assumes current is injected at a single point on the surface into a homogeneous half-space. It overestimates local potentials for extended electrodes but is conservative for early design checks.

Vertical rod approximate formula (finite electrode)

V(r) ≈ (ρ * I) / (2 * π * L) * [ln(2 * L / r) + α]

Variables:

- L = effective rod length or equivalent electrode length (m)

- α = geometry-dependent constant (typically between −0.5 and 0.5 depending on grounding end conditions)

Typical values: ρ = 200 Ω·m, I = 5000 A, L = 3 m, r = 1 m, α = −0.5 gives an approximate V(1) ≈ (200*5000)/(2π*3)*[ln(6/1)-0.5] ≈ ... (compute numerically in examples below).

Notes: This formula is a simplified representation of results from vertical electrode theory. Many calculators use refined expressions derived from IEEE Std 80 or numerical BEM/FEM models for more accuracy.

Key safety thresholds and normative references

Designers must compare calculated step and touch voltages to tolerated values in recognized standards. A non-exhaustive set of references includes:

- IEEE Std 80: Guide for Safety in AC Substation Grounding — provides methods to compute potentials and permissible touch/step voltages for different exposure durations. https://standards.ieee.org/standard/80-2013.html

- IEC 60479: Effects of current on human beings and livestock — provides physiological response guidance. https://www.iec.ch

- IEC 62305 / IEC 60099 family and lightning protection guides — for lightning-related ground potentials. https://www.iec.ch

- NESC (National Electrical Safety Code) / local utility earthing guidelines — for transmission and distribution earthing requirements. https://standards.ieee.org/other/nesc/

- OSHA electrical safety standards and guidance related to grounding and fault conditions. https://www.osha.gov

Always retrieve the latest versions and country-specific regulations; IEEE and IEC are primary technical authorities for step and touch calculations.

Typical soil resistivity and grounding parameter tables

| Soil type | Typical resistivity (Ω·m) | Notes |

|---|---|---|

| Dry sand | 300–1000 | Low moisture, high resistivity; deep electrodes recommended |

| Gravel | 100–1000 | Heterogeneous, variable resistivity |

| Loam (dry) | 100–500 | Moderate resistivity; improved by moisture control |

| Clay | 10–200 | Good conductivity when moisture present |

| Peat / organic | 50–500 | Variable, moderate conductivity but compressible |

| Rock / granite | 1000–>10000 | Very high resistivity, requires deep counterpoise |

| Exposure duration | Typical design limit for touch (indicative) | Typical design limit for step (indicative) |

|---|---|---|

| Short faults (t ≤ 0.2 s) | Higher transient allowable values (consult IEEE Std 80) | Higher transient allowable values (consult IEEE Std 80) |

| Intermediate (0.2 s < t ≤ 3 s) | Moderate limits depending on body current criteria | Moderate limits |

| Continuous exposure | Low limits (e.g., tens of volts for public areas) | Low limits |

Calculator features that determine "best safety"

A best-in-class step and touch voltage calculator should include the following capabilities:

- Multi-layer soil modeling with lateral and vertical heterogeneity.

- Full three-dimensional numerical techniques (BEM/FEM) for complex geometries.

- Automatic mesh refinement near electrodes, conductors, and structures.

- Support for multiple fault scenarios and varying fault durations.

- Calculation of equipotential surfaces and gradient vectors for safety planning.

- Output of step/touch voltages at user-defined points and along paths.

- Design optimization tools: mesh sizing, conductor sizing, and counterpoise requirements.

- Standards compliance modes (IEEE Std 80, IEC annexes) for automated checks.

Human safety modeling capabilities

- Ability to compute body-current paths and expected current for given touch/step voltages.

- Integration of IEC 60479 curves or equivalent models to compute physiological risk metrics.

- Support for footwear insulation factors, barefoot conditions, and partial contact scenarios.

Step and touch voltage mitigation measures evaluated by calculators

- Mesh conductors and equipotential bonding to reduce potential gradients at the surface.

- Buried copper mats or concrete-encased grids to spread current and reduce local potentials.

- Ring counterpoise conductors around structures to intercept fault current before it enters the surface near users.

- Isolating insulating barriers, raised platforms, and bonding of exposed structures.

- Use of low-resistivity backfill (conductive cement, bentonite) to lower local resistivity.

Example 1 — Single vertical rod: step and touch approximate assessment

Scenario: A remote pole uses a single vertical ground rod. Design engineer must estimate worst-case step and touch voltages for a dead-short fault of 5000 A lasting 0.5 s. Soil is reasonably conductive with ρ = 200 Ω·m. Rod length L = 3 m. We evaluate potentials at r = 0.5 m, r = 1.0 m, and the step voltage between r = 1.0 m and r = 2.0 m.

Step-by-step calculation

- Use the vertical rod approximation: V(r) ≈ (ρ * I) / (2 * π * L) * [ln(2 * L / r) + α]. Choose α = −0.5 for a conservative estimate.

- Compute the constant factor K = (ρ * I) / (2 * π * L).

K = (200 Ω·m * 5000 A) / (2 * π * 3 m) = (1 000 000) / (18.8496) ≈ 53 051 V.

- Compute V(0.5): argument ln(2*L/r) = ln(6/0.5) = ln(12) ≈ 2.4849. Then bracket = 2.4849 − 0.5 = 1.9849.

V(0.5) ≈ K * 1.9849 ≈ 53 051 * 1.9849 ≈ 105 350 V.

- Compute V(1.0): ln(6/1) = ln(6) ≈ 1.7918. Bracket = 1.7918 − 0.5 = 1.2918.

V(1.0) ≈ 53 051 * 1.2918 ≈ 68 530 V.

- Compute V(2.0): ln(6/2) = ln(3) ≈ 1.0986. Bracket = 1.0986 − 0.5 = 0.5986.

V(2.0) ≈ 53 051 * 0.5986 ≈ 31 750 V.

- Estimate step voltage between r = 1.0 and r = 2.0 as ΔV_step ≈ |V(1.0) − V(2.0)| ≈ 68 530 − 31 750 ≈ 36 780 V.

- Interpretation: These are large potentials; the single rod is insufficient. Design must include counterpoise or grid to reduce gradients.

Discussion and mitigation

- Calculation shows single-rod potentials are high for the assumed fault. A ground grid or ring conductor will reduce both V(0.5) and step voltage drastically by spreading fault current.

- Use of low-resistivity backfill or multiple rods interconnected reduces the equivalent K factor, proportionally lowering V(r).

- Actual design must use IEEE Std 80 numerical methods or a validated calculator for compliance verification.

Example 2 — Substation grid design verifying compliance

Scenario: Design a substation 33/11 kV with expected maximum bolted fault contribution to ground I_fault = 12 000 A for 0.2 s. Soil is layered: top layer 10 m at ρ1 = 150 Ω·m, underlying half-space ρ2 = 500 Ω·m. Objective: verify mesh size and grid conductor spacing to keep maximum tolerable touch voltage within allowable limits per design criteria.

Inputs to the calculator

- I_fault = 12 000 A, t_fault = 0.2 s

- Layer 1: thickness h1 = 10 m, ρ1 = 150 Ω·m

- Layer 2: half-space ρ2 = 500 Ω·m

- Proposed grid: 50 mm × 6 mm copper conductors, mesh 3 m × 3 m, buried 0.3 m below grade.

- Plots and points requested: potential contour every 100 V, step voltage between grid nodes, touch voltage at structure locations.

Methodology

- Generate layered earth response transfer functions or use numerical BEM solver that accepts layered resistivity.

- Model grid conductors as distributed line elements with conductor resistance computed from geometry and temperature.

- Inject I_fault at transformer neutral node and compute surface potentials across discretized grid.

- Compute ΔV_step across typical human step distance (1 m) and touch potentials for typical structure heights.

Representative calculation steps (simplified)

Because the problem requires layered earth modeling, here is a simplified illustration using an equivalent single-layer approximation for conservative estimation. Compute apparent resistivity ρ_eq using weighted approximation (conservative choose ρ_eq = ρ1 = 150 Ω·m for upper-layer control).

Compute approximate surface potential using distributed grid model where grid reduces surface resistivity. For a well-interconnected grid, the effective K is reduced by factor η dependent on grid footprint and mesh size. For an initial conservative estimate assume η = 0.05 (i.e., 5% of point-source potential).

Using point-source baseline V_point at r = 1 m: V_point ≈ (ρ_eq * I_fault) / (2 * π * 1) = (150 * 12 000) / (6.2832) ≈ 286 478 V.

Apply grid reduction: V_grid ≈ η * V_point = 0.05 * 286 478 ≈ 14 324 V at 1 m from injection node (conservative estimate).

Step voltage across 1 m near the transformer region often decreases by gradient; assume a local gradient ratio giving ΔV_step ≈ 0.3 * V_grid ≈ 4 297 V.

Interpretation and next steps

- The approximate ΔV_step is still very high, indicating further mitigation is required: denser mesh (e.g., 1 m × 1 m), additional buried mats, and increased conductor size to lower η significantly.

- Use of full BEM/FEM simulation will yield accurate potentials; iterative design can determine minimum mesh size and counterpoise geometry to meet the allowable touch/step voltages per IEEE Std 80 limits.

- Illustrative conclusion: A grid with 1 m mesh and conductive backfill may reduce η to 0.005–0.01, bringing ΔV_step into low hundreds of volts or less, depending on exact parameters.

Practical measurement verification and field testing

After installation, field verification should be performed:

- Measure ground grid resistance to remote earth with fall-of-potential tests or clamp-on testers where applicable.

- Perform soil resistivity surveys using Wenner or Schlumberger methods across the site.

- Perform step and touch voltage field checks using calibrated test equipment following safety procedures, especially when energizing for the first time.

Fall-of-potential test formula

Variables:

- Rg = measured ground resistance (Ω)

- V_test = measured voltage between probe and grounding system (V)

- I_test = test current injected (A)

Software validation, uncertainty, and model verification

Best practice requires verification of any calculator or software tool against:

- Analytical solutions for canonical problems (single rod, infinite plate).

- Benchmark cases provided in IEEE Std 80 and academic literature.

- Field measurements on pilot installations to tune model parameters (soil layering and contact resistances).

Uncertainty sources

- Soil resistivity variability (seasonal moisture, temperature).

- Contact resistance at buried conductors and electrodes.

- Assumptions about fault current distribution and contribution from nearby grounded systems.

- Human factor assumptions (barefoot vs. insulated footwear, step length).

UX considerations for professional calculators

High-utility calculators must present results clearly and allow rapid iteration:

- Graphical potential contour plots and gradient vector fields.

- Tabular outputs with maximum step and touch voltages at user-specified locations.

- Exportable reports for regulatory submission with calculation assumptions and norms referenced.

- Automated checks against standard permissible values and flags for non-compliance.

Checklist for engineers using step and touch voltage calculators

- Confirm latest versions and normative modes (IEEE, IEC) in the tool.

- Collect comprehensive site data: soil resistivity, layering, seasonal variations, nearby grounded systems.

- Define representative fault scenarios: magnitude, duration, and multiple simultaneous faults if applicable.

- Model complete geometry: structures, conductive surfaces, buried metallic assets.

- Run sensitivity analyses: vary soil resistivity, mesh size, conductor sizes, and backfill properties.

- Validate against analytical cases and, if possible, field measurements.

- Document mitigation strategies and produce an actionable implementation plan.

Common mistakes and how calculators prevent them

- Neglecting layered soil effects: calculators with multi-layer capability avoid unsafe underestimation of potentials.

- Using single-point electrode assumptions for extended grids: refined solvers model current distribution correctly.

- Ignoring equipotential bonding: calculators that model bonding show the benefit of connecting metallic structures.

- Assuming nominal soil resistivity rather than measured values: integrated resistivity import avoids large errors.

Regulatory and documentation best practices

For regulatory acceptance and stakeholder communication, provide:

- Clear statement of calculation assumptions, input data, and solver settings.

- Comparison tables showing calculated vs. allowable step/touch voltages with normative references.

- Design drawings indicating grid geometry, conductor sizes, and locations of measurement points.

- Post-installation test plans and a schedule for periodic re-evaluation if environmental conditions change.

Sample output table for reports

| Location | V_surface (V) | ΔV_step (V) | V_touch (V) | Compliance status |

|---|---|---|---|---|

| Transformer neutral pit | 150 | 45 | 120 | Check per IEEE Std 80 |

| Control building entrance | 12 | 4 | 10 | Within public limits |

| Substation yard center | 80 | 26 | 70 | Within worker limits |

Final recommendations for selecting a step and touch voltage calculator

- Choose a tool that supports layered soils and 3D numerical solvers for complex sites.

- Ensure the software includes standards-driven validation routines and can generate compliance reports.

- Look for tools that allow parametric studies and optimization to minimize cost while achieving safety.

- Prefer vendors who provide benchmark case results and documented verification against IEEE Std 80 examples.

Further reading and authoritative resources

- IEEE Std 80 — Guide for Safety in AC Substation Grounding. Available from IEEE Standards Association: https://standards.ieee.org/standard/80-2013.html

- IEC Publications related to earthing and effects of current on humans: https://www.iec.ch

- OSHA electrical safety guidance and grounding references: https://www.osha.gov

- NESC and local utility earthing manuals for transmission and distribution systems.

Using advanced and validated step and touch voltage calculators is a regulatory and ethical requirement in contemporary power systems engineering. Robust input data, iterative design, and rigorous verification ensure protection of personnel and equipment under fault conditions.