Minimum separation calculators ensure safe distances for electrical equipment per regulatory and design requirements worldwide.

This article explains calculation methods, practical examples, normative references, and recommended calculator features for engineers.

Minimum Separation IEC Calculator — Technical Clearance & Creepage

Regulatory framework and standards referenced for minimum separation

Design of minimum separations between conductors and live parts must follow established international standards. The core reference for insulation coordination in low-voltage equipment is IEC 60664-1 (Insulation coordination for equipment within low-voltage systems). Additional product-specific standards apply: IEC 62368-1 (audio/video and ICT equipment), IEC 61010-1 (measurement, control and lab use), IEC 61508/IEC 62061 (functional safety implications for separation), and product safety directives such as the Low Voltage Directive (2014/35/EU) where applicable. For material properties and flammability tests, UL 94 and IEC 60695 series are commonly referenced.

Key normative documents and authoritative sources

- IEC 60664-1: Insulation coordination — provides tabulated minimum clearances and creepage for various rated voltages and pollution degrees. Reference: https://www.iec.ch

- IEC 62368-1: Equipment safety for IT and A/V — product-specific requirements and functional insulation examples. Reference: https://webstore.iec.ch

- IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and laboratory use. Reference: https://webstore.iec.ch

- NIST and peer-reviewed sources for dielectric strength values of air and materials (for engineering estimations). Example resource: https://www.nist.gov

- Industry guidance and datasheets for material CTI (Comparative Tracking Index) and group classifications used in creepage calculations.

Essential inputs and outputs for a best-practice minimum separation calculator

A professional calculator must accept inputs describing the electrical and environmental operating regime, material properties, and altitude. Outputs should include both recommended clearance (air gap) and creepage (surface path) distances, intermediate calculation steps, and references to the normative table entries used.

Minimum required input parameters

- Working voltage (AC RMS, DC, or peak values as applicable)

- Overvoltage category or impulse withstand rating (if known)

- Pollution degree (PD 1–4 per IEC definitions)

- Material group (based on CTI or manufacturer data)

- Type of insulation required (basic, supplementary, double, reinforced)

- Altitude above sea level (m)

- Operating environment (clean indoor, industrial, outdoor, contaminated)

- Required safety factor or target reliability (optional advanced input)

Typical outputs

- Minimum clearance (air gap) in mm

- Minimum creepage distance in mm

- Derating factors applied (altitude, humidity, pollution)

- Applicable normative table references and selected table rows

- Assumptions and uncertainty notes

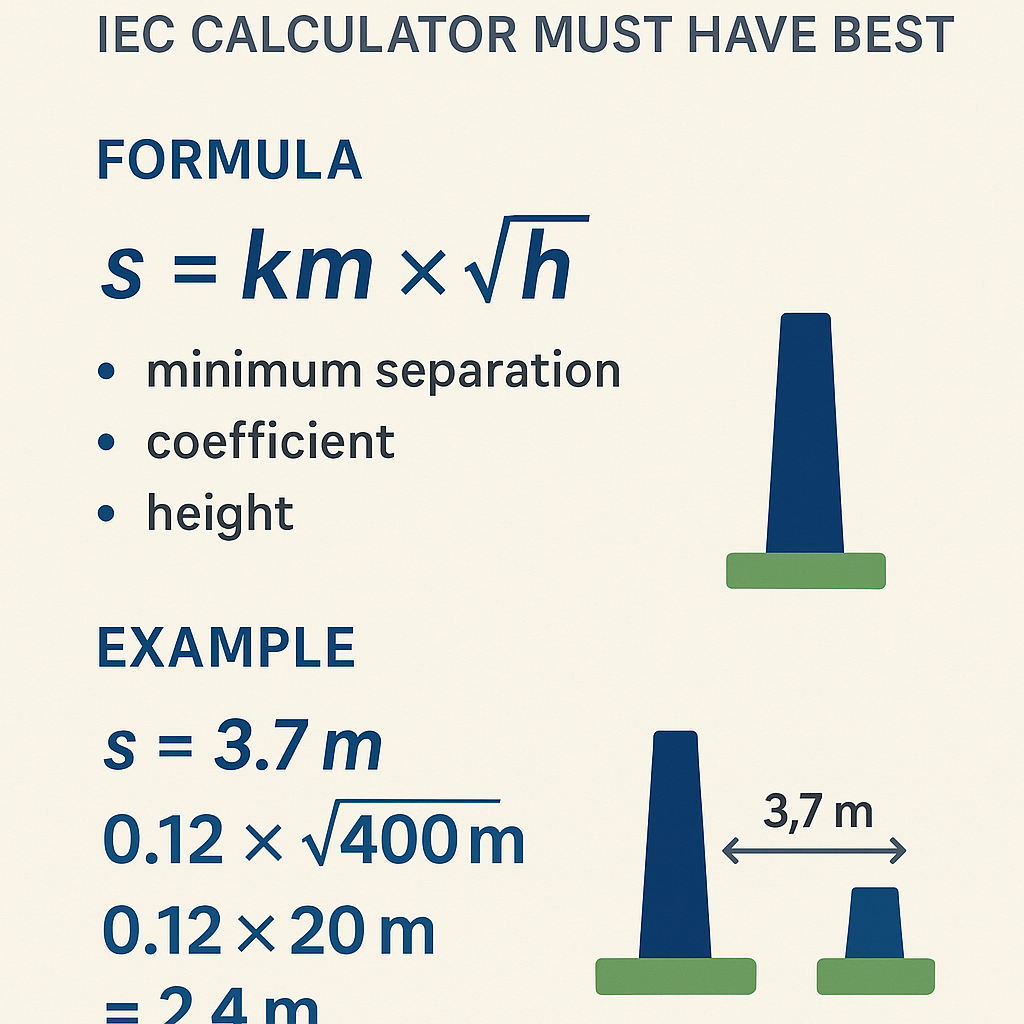

Fundamental engineering formulas (HTML-only format)

Below are practical formulas used by calculators to estimate preliminary minimum separations. These are engineering approximations for early-stage design; final values must be verified directly against IEC normative tables.

Formula for basic air-gap estimate using dielectric strength:

Where:

- S_air_est = estimated air gap (mm)

- U_working_kV = working voltage in kilovolts (kV). For AC systems, use peak voltage: U_peak = U_rms * sqrt(2)

- E_air_kV_per_mm = usable dielectric strength of air (typical conservative value 3.0 kV/mm at standard conditions)

Apply a safety multiplier for non-uniform fields, pollution, and manufacturing tolerances:

Where SF is safety factor (typical engineering values: 2.0 to 4.0 depending on pollution degree and field uniformity).

Creepage distance empirical estimator (rule-of-thumb approach):

Where:

- L_creep_est = estimated creepage (mm)

- D_factor = creepage factor (mm/kV) determined by material group and pollution degree (typical engineering ranges 2–25 mm/kV)

Altitude derating (practical conservative model):

Where:

- h_meters = installation altitude above sea level in meters

- Altitude_factor = multiplier applied to S_air_required and L_creep_est (example: at 2000 m factor = 2.0)

Combined required clearance including altitude:

Notes on variables and typical values:

- E_air_kV_per_mm — conservative baseline 3.0 kV/mm for dry air at sea level. Use 1.5–2.5 kV/mm for humid or contaminated environments.

- SF (safety factor) — 2 for clean indoor (PD2, uniform conductor shapes), 3 for industrial, 4 for outdoor / high pollution / sharp edges.

- D_factor — consult material CTI classification; typical examples provided in tables below.

Tables of typical values and lookup aids

| Medium / Material | Typical dielectric strength (kV/mm) | Notes and typical usage |

|---|---|---|

| Dry air (clean, 1 atm) | 3.0 | Baseline engineering value for uniform fields; IEC design uses tabulated clearances instead of direct formula. |

| Humid/contaminated air | 1.5–2.5 | Use lower end for heavy condensation or salt fog environments; increases required clearance. |

| Epoxy / FR4 (solid dielectric) | 20–40 | Solid dielectric breakdown far higher; creepage still governs surface tracking. |

| Ceramics (dense) | 30–50 | Used for high-voltage insulation components; high dielectric strength. |

| Pollution degree | Typical description | Recommended SF (safety factor) | Typical creepage factor (mm/kV) D_factor |

|---|---|---|---|

| PD 1 | No pollution or only dry, non-conductive pollution | 1.5–2.0 | 2–4 |

| PD 2 | Only non-conductive pollution; temporary condensation | 2.0–2.5 | 4–8 |

| PD 3 | Conductive pollution or long-term condensation | 3.0 | 8–15 |

| PD 4 | Persistent conductive pollution or corrosion | 3.5–4.0 | 15–25 |

| Common working voltage | Estimated minimum clearance S_final (mm) | Estimated creepage L_creep_est (mm) | Assumptions |

|---|---|---|---|

| 24 V DC | 0.5–1.5 | 2–10 | PD2, SF=2, D_factor 2–4 |

| 60 V DC / 48 V nominal | 1–2 | 4–12 | PD2, SF=2–2.5 |

| 230 V AC (mains) | 3–6 | 12–40 | U_peak=325 V, SF 2–3, PD2–3 |

| 400 V AC three-phase | 6–12 | 24–80 | U_phase-phase peak ~565 V, SF 2–3 |

| 1000 V DC (PV systems) | 50–150 | 150–1000 | High pollution possibilities, SF 3–4, PD3–4 |

Detailed algorithmic flow a robust calculator must implement

High-quality calculators implement both rule-of-thumb estimators for rapid feedback and normative-table lookups for compliance. The algorithm should be deterministic, auditable, and provide traceable mappings to IEC table rows.

Calculation pipeline

- Normalize user inputs to canonical units (kV for voltage, mm for lengths, meters for altitude).

- Convert AC RMS to peak where peak field drives breakdown: U_peak = U_rms * sqrt(2).

- Select relevant normative table set based on equipment class (IEC 60664-1 general rules; IEC 62368-1 for IT/A/V).

- Estimate baseline clearance using dielectric strength model: S_air_est = U_peak / E_air.

- Apply safety factor based on pollution degree, material group, and geometry: S_air_required = SF * S_air_est.

- Apply altitude correction: S_final = S_air_required * Altitude_factor.

- Estimate creepage: L_creep_est = U_working_kV * D_factor, then apply pollution and material modifications.

- Cross-check derived S_final and L_creep_est against IEC normative minimums and output the larger value where applicable.

- Document the normative row used and produce a traceable audit report with assumptions and sensitivity.

Usability and UX features the best calculators must provide

Engineers require a calculator that is accurate, auditable, and integrates well into design workflows. Below are essential UX and functional features.

Mandatory UX / functional items

- Traceable references: show which IEC table and row was used and the normative clause number.

- Step-by-step calculation trace with numeric intermediate values and units.

- Ability to switch between simplified estimator mode and standards-compliant mode.

- Altitude, humidity, and pollution toggles with recommended default values and tooltips.

- Material library for CTI and material group assignment, including ability to add vendor-specific data.

- Exportable report (PDF/CSV) with inputs, outputs, calculation trace, and normative references.

- Versioning of normative tables and a changelog indicating the standard edition used.

- Unit conversions and support for AC/DC peak/rms selection with automatic conversion.

Practical worked examples

Two fully worked cases follow. Each example lists inputs, assumptions, intermediate calculations, and the final recommended clearance and creepage distances. These examples use the conservative engineering formulas described above and note where the IEC tables must be consulted for final verification.

Case 1 — Single-phase 230 V AC device, indoor consumer electronics (PD2)

Inputs and assumptions:

- Nominal voltage: 230 V AC (RMS)

- U_peak = 230 * sqrt(2) = 325.3 V => U_working_kV = 0.325 kV

- Pollution degree: PD2 (normal indoor)

- Material group: IIIa (typical plastic-coated PCBs, CTI moderate)

- Altitude: 0 m (sea level)

- E_air_kV_per_mm = 3.0 kV/mm (dry indoor)

- Safety factor SF = 2.0 (PD2, relatively benign environment)

- Creepage D_factor = 6 mm/kV (material group IIIa, PD2 conservative value)

Step-by-step calculations:

1) Baseline air gap estimate:

2) Apply SF:

3) Apply altitude factor (sea level):

4) Creepage estimate:

Interpretation and normative check:

- The calculated air-gap S_final ≈ 0.22 mm is a theoretical minimal value from the dielectric-strength method; manufacturing tolerances and normative minimums typically mandate larger clearances.

- IEC normative tables for 230 V circuits and basic insulation commonly specify minimum clearances larger than the raw dielectric estimate. Typical product practice for mains-connected appliance PCBs uses a clearance of at least 3.0 mm to 4.0 mm for basic insulation in PD2 conditions—this is reflected in IEC tables and product-type standards.

- Therefore, the final recommended clearance must be selected as the maximum of the calculated S_final and the normative table minimum. For this example, select 3.0 mm clearance and creepage of at least 12 mm (industry practice for double insulation or user-accessible mains regions may demand even higher distances).

Final recommendation (practical): Clearance = 3.0 mm, Creepage = 12 mm. Validate against IEC 60664-1 table rows applicable to mains voltage and insulation type before release.

Case 2 — Photovoltaic inverter DC bus 1000 V DC, outdoor installation (PD3)

Inputs and assumptions:

- Nominal DC voltage: 1000 V DC

- U_working_kV = 1.0 kV (DC value used directly)

- Pollution degree: PD3 (outdoor with possible conductive pollution)

- Material group: II (insulating material with moderate CTI)

- Altitude: 1500 m

- E_air_kV_per_mm = 2.0 kV/mm (reduced due to humidity and contaminants)

- Safety factor SF = 3.0 (PD3 harsh environment)

- Creepage D_factor = 15 mm/kV (conservative for PD3 and material group II)

Step-by-step calculations:

1) Baseline air gap estimate:

2) Apply SF:

3) Altitude factor:

4) Creepage estimate:

Interpretation and normative check:

- The computed S_final ≈ 2.63 mm is a conservative engineering estimate considering field and altitude. However, IEC 60664-1 and PV-specific guidance often require substantially larger clearances for DC systems and consideration of pollution class and surge-related overvoltages.

- Industry practice and IEC guidance for 1000 V DC outdoor PV equipment commonly yields recommended clearances in the range of 20–50 mm and creepage distances in the hundreds of millimeters when long-term tracking and contamination are likely. The calculated dielectric-based S_final must therefore be compared against the IEC normative table and product standard minima; the normative minima will typically govern.

Final recommendation (practical): Use the larger of S_final and the IEC table minimum. For this example, follow IEC table for 1 kV DC in PD3: practical selection may be Clearance = 50 mm and Creepage = 300 mm depending on the equipment enclosure and required pollution tolerance. Consult IEC 60664-1 and PV product standards for exact numeric table values.

Validation, testing, and manufacturing considerations

Designers must remember that calculators provide design intent and preliminary dimensions. Validation requires laboratory testing: impulse withstand tests, partial discharge, humidity chamber tests, and routine production inspection.

Recommended verification steps

- Cross-check calculated clearances against the exact IEC table rows for the equipment insulation level and working voltage.

- Perform impulse withstand testing per product standard clauses (e.g., lightning and switching impulses where specified).

- Perform pollution and tracking tests (e.g., CTI tests and tracking index validation) for creepage design verification.

- Include assembly tolerances and conformal coatings (if used) in manufacturing drawings; coatings alter creepage but must be tested per IEC guidance.

- Use coordinate inspection and optical metrology during production to confirm minimum distances are maintained on assembled units.

Implementation notes for an IEC-compliant calculator

When implementing a calculator intended for compliance evaluation, ensure the following technical aspects:

Data and traceability

- Include the edition and clause number of IEC normative tables used. If tables are updated, allow the user to choose standard edition.

- Record user-supplied assumptions and environmental overrides in any generated report.

- Provide a deterministic audit trail — inputs, intermediate steps with units, normative lookup results, and final outputs.

API and integration

- Offer REST API endpoints for automated design tools to query clearance and creepage recommendations.

- Support batch processing of multiple circuits and BOM-linked material properties.

- Allow import/export of material property libraries (CTI, dielectric constants) from supplier datasheets for accurate creepage estimations.

Limitations and safe practice reminders

Calculators are engineering aids, not a replacement for the standards documents themselves. Always validate final designs with the normative tables in IEC 60664-1 and product-specific standards. Where standard tables prescribe specific minimums for a given rated voltage, insulation level, pollution degree, and material group, these prescriptive values take precedence over formulaic estimations.

Practical safety checklist for release to manufacture

- Confirm normative table mapping for the final selected insulation type and working voltage.

- Check material CTI values with vendor test data.

- Account for manufacturing tolerances and conformal coatings — update drawings accordingly.

- Document test plans for type testing and routine verification.

- Ensure regulatory dossier includes normative citations and a compliance rationale supported by test evidence.

References and further authoritative reading

- IEC 60664-1: Insulation coordination for equipment within low-voltage systems — official standard and tables. https://www.iec.ch

- IEC 62368-1: Audio/video, information and communication technology equipment — safety requirements. https://webstore.iec.ch

- IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and laboratory use. https://webstore.iec.ch

- NIST reference materials and publications on dielectric properties of gases and solids. https://www.nist.gov

- Manufacturer material datasheets for CTI and dielectric strength (consult for specific polymer grades).

Summary of best-practice features to include in a "must-have" IEC minimum separation calculator

- Standards edition selector with clause-level citations.

- Dual-mode calculations (quick estimator and standards lookup).

- Complete audit trail, report export, and API integration.

- Material database with CTI, dielectric strength, and vendor overrides.

- Environmental derating (pollution, altitude, humidity) and conservative default values.

- User guidance and final normative value enforcement (i.e., always return the higher of computed vs. table-mandated minimum).

Engineers must treat calculator outputs as design guidance. Final values must be cross-checked with the applicable IEC normative tables and validated by testing before product certification and release.