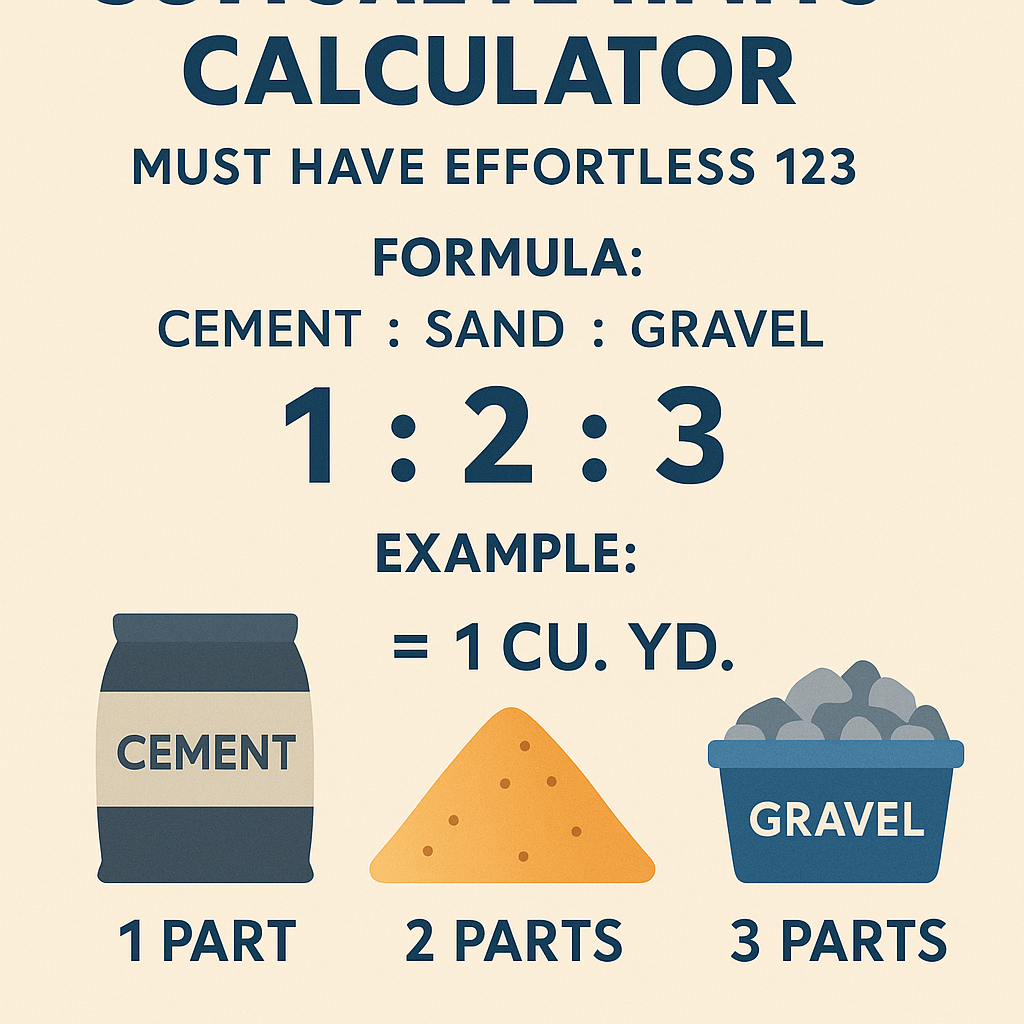

Accurate concrete ratios prevent structural failures and optimize materials, cost, and workability on projects daily.

This article explains the Concrete Ratio Calculator method, formulas, examples, and compliance with standards requirements.

Concrete Mix Material Calculator — Ratio-based (absolute volume method)

Concrete Ratio Calculator: technical scope and purpose

Concrete mix design and ratio calculation are central to ensuring structural performance, durability, and economy. A Concrete Ratio Calculator must convert design requirements into actionable material quantities, considering volumetric proportions, densities, moisture, bulking, and site wastage. The tool should produce quantities in common construction units: cubic meters (m3), kilograms (kg), and number of cement bags. A robust calculator distinguishes between nominal mixes and designed mixes. Nominal mixes (e.g., 1:2:4 by volume) are simplified ratios for small works, while designed mixes (e.g., M20, M25) derive from laboratory testing to meet specified compressive strength, exposure class, and service life. This article details the mathematical foundation, variables, correction factors, and worked examples used in professional Concrete Ratio Calculators.Key variables, parameters, and their typical values

Primary variables and definitions

- Total concrete volume (V): volume of fresh concrete required, usually in m3.

- Mix proportions (Pc:P s:P a): volumetric ratio of cement (c), sand (s), and aggregate (a).

- Cement content (Cvol): volume of cement per unit concrete volume (m3).

- Dry-rodded volume correction (bulking and compaction): accounts for compacted vs loose volume.

- Unit weights/densities: bulk densities of materials, used to convert volumes to mass.

- Water-cement ratio (w/c): mass of water divided by mass of cement; critical for strength and durability.

- Wastage factor (Wf): percentage allowance for site losses (typically 2–5%).

Typical numerical values for variables

- Standard cement bag mass: 50 kg (common in many regions).

- Bulk density (approximate): cement 1440 kg/m3, sand (dry) 1600 kg/m3, coarse aggregate 1500–1700 kg/m3.

- Free water for nominal mixes: 0.4–0.6 by mass of cement depending on workability.

- Bulking of sand: 0–30% depending on moisture; use typical correction 0–10% for calculation examples.

- Wastage allowance: 2–5% for sand and aggregate, 1–2% for cement.

Fundamental formulas and calculus used in calculators

Volume proportion formulas (by volume)

Material volumes and mass conversion (per unit concrete volume)

Bag count and water calculation

Example of a formula presented as HTML text

Where:

- Mass_cement is in kg per total concrete volume V (m3)

- V is total concrete volume in m3

- Pc, Ps, Pa are the volumetric parts for cement, sand, and aggregate

- Density_cement is typically 1440 kg/m3

Correction factors and practical adjustments

Bulking of sand

Bulking increases apparent sand volume when moist. Correction factor should be applied to convert apparent wet sand volume to oven-dry equivalent. Typical approach:

Bulking_percentage typical: 0.00 to 0.30 (0%–30%). For common practice use 0.05–0.10 for slightly moist sand.

Compaction and shrinkage allowances

Allowance for compaction: volume of compacted concrete is less than loose aggregate sum; calculators often use a reduction factor (e.g., 0.98–0.99) for concrete consolidation and vibration.

Shrinkage is a property of hardened concrete and not directly used to size initial mix quantities; however, for very low water-cement mixes, reduced yield should be anticipated due to bleeding and segregation.

Wastage and delivery loss

Typical Wf values: cement 0.01–0.02, sand 0.02–0.05, aggregate 0.02–0.05.

Extensive tables with common values

| Nominal Mix | Volumetric Ratio (C:S:A) | Approx. 28-day Strength (MPa) | Typical Application |

|---|---|---|---|

| M5 | 1:5:10 | ~5–7 | Plain concrete, blinding |

| M10 | 1:3:6 | ~10 | Non-structural footings, foundations |

| M15 | 1:2:4 | ~15 | Light-duty slabs, low-rise floors |

| M20 | 1:1.5:3 | ~20 | Beams, columns, slabs for moderate loads |

| M25 | 1:1:2 | ~25 | Structural elements, reinforced concrete |

| M30 | 1:0.75:1.5 | ~30 | High-strength structural components |

| Material | Bulk Density (kg/m3) | Typical Bag Size | Remarks |

|---|---|---|---|

| Ordinary Portland Cement (OPC) | 1440 | 50 kg | Adopt local bag mass if different |

| Fine Aggregate (Sand) | 1600 | N/A | Dry-rodded; adjust for bulking |

| Coarse Aggregate (20 mm) | 1500–1700 | N/A | Use specific gravity and particle shape factors |

| Water | 1000 | 1 litre ≈ 1 kg | Fresh potable water recommended |

| Parameter | Typical Range | Design Implication |

|---|---|---|

| Water/cement ratio (w/c) | 0.35–0.60 | Lower w/c increases strength, reduces workability |

| Air entrainment | 0.5–6% (depending on frost exposure) | Improves freeze-thaw durability |

| Slump | 10–150 mm | Indicator of workability; adjust water or admixture |

| Wastage allowance | 1–5% | Use conservative values for manual batching |

Calculator workflow: step-by-step algorithm

- Define total required fresh concrete volume V (m3) including formwork tolerances.

- Select target mix or nominal ratio (Pc:Ps:Pa) and target w/c ratio for design strength.

- Compute volumetric fractions Cvol, Svol, Avol by dividing parts by the sum S.

- Apply bulking and moisture correction to sand volume where applicable.

- Convert material volumes to masses using bulk densities.

- Apply wastage factors and convert cement mass to number of bags.

- Output quantities and checks: total mass, water content, cement content per m3.

- Optionally provide durability checks against codes and exposure classes.

Real-world example 1: Foundation footing — M20 nominal mix

Problem statement and assumptions

Excavate a continuous strip footing of dimensions: length 6.0 m, width 0.6 m, depth 0.3 m. Use M20 nominal mix 1:1.5:3. Assume no bulking, cement bag = 50 kg, densities: cement 1440 kg/m3, sand 1600 kg/m3, aggregate 1550 kg/m3. Wastage: cement 1.5%, sand and aggregate 3% each. w/c = 0.50.

Step-by-step solution

1. Calculate total concrete volume V:

2. Mix ratio Pc:Ps:Pa = 1 : 1.5 : 3. Sum S = 1 + 1.5 + 3 = 5.5

3. Volumes of constituents (as compacted volumes) per total concrete volume V:

Cement_volume = V * (Pc / S) = 1.08 * (1 / 5.5) = 1.08 * 0.181818 ≈ 0.19636 m3

Sand_volume = V * (Ps / S) = 1.08 * (1.5 / 5.5) = 1.08 * 0.272727 ≈ 0.29454 m3

Aggregate_volume = V * (Pa / S) = 1.08 * (3 / 5.5) = 1.08 * 0.545455 ≈ 0.58909 m3

4. Convert volumes to mass using densities:

5. Apply wastage factors:

6. Cement bags:

Summary solution — Footing quantities

- Total concrete volume: 1.08 m3

- Cement required: 287.94 kg → 6 bags (50 kg each)

- Sand required: 485.40 kg (~0.303 m3 if verified by dividing by density)

- Aggregate required: 940.48 kg (~0.606 m3)

- Water required: 144 litres (adjust for moisture in sand)

Real-world example 2: Slab on ground — M25 designed mix with bulking

Problem statement and assumptions

Construct a reinforced concrete slab: length 5.0 m, width 4.0 m, thickness 0.125 m (125 mm). Target M25 with nominal volumetric equivalent 1:1:2 (Pc:Ps:Pa). Use bag mass 50 kg. Densities: cement 1440 kg/m3, sand 1620 kg/m3, aggregate 1600 kg/m3. Sand bulking 8% (0.08). Wastage: cement 2%, sand and aggregate 3%. w/c = 0.45.

Step-by-step solution

1. Volume V:

3. Volumes per total V:

4. Correct sand for bulking (8%):

5. Convert volumes to mass:

6. Apply wastage factors:

7. Cement bags and water:

Checks and remarks

- Cement content per m3 = 918 / 2.5 = 367.2 kg/m3 — consistent with M25 mix design targeted cement content (confirm with local code).

- Aggregate absolute volume check: sum of material volumes versus V should match after considering packing and voids; small deviations require adjustment in proportioning or use of volume change correction factors.

- Round up cement bags conservatively to avoid shortage; remaining minor excess can be used for curing and small repairs.

Design checks and code references

Concrete Ratio Calculators should integrate checks against applicable design codes for durability, minimum cement content, and water-cement ratio limits. Consult the following standards for authoritative criteria:

- ACI 318 Building Code Requirements for Structural Concrete — American Concrete Institute (https://www.concrete.org)

- BS EN 206: Concrete — Specification, performance, production and conformity — British Standards Institution (https://www.bsigroup.com)

- IS 456: Plain and Reinforced Concrete — Code of Practice (for Indian projects) (https://bis.gov.in)

- IS 10262: Concrete Mix Proportioning — Guidelines for concrete mix design (https://bis.gov.in)

- Eurocode 2: Design of concrete structures (https://eurocodes.jrc.ec.europa.eu)

Typical normative checks implemented by calculators

- Minimum cement content per exposure class.

- Maximum permissible w/c ratio to ensure required durability.

- Minimum cement content per unit volume for crack control.

- Limit on total water content to remain within slump requirements.

Errors, limitations, and calibration recommendations

Concrete Ratio Calculators are models and must be calibrated against laboratory trial mixes and site conditions. Common sources of error include inaccurate bulk density values, unaccounted moisture in aggregates, and failure to apply bulking corrections to sand.

- Always measure actual density of aggregates from supplier sampling (unit weight varies widely).

- Conduct trial mixes for designed concrete to confirm workability and strength before full-scale production.

- Incorporate admixture effects: plasticizers reduce water demand; air-entrainers change volume slightly.

- For pumped concrete, adjust proportions for pumpability and reduce maximum aggregate size if necessary.

UX considerations for an effortless "123" Calculator

To be practical and effortless, implement these UX features:

- Simple inputs: length, width, depth, mix selection (dropdown including nominal mixes and M-designations).

- Advanced toggle: allow input of densities, bulking percentage, and wastage per material.

- Immediate outputs: quantities for each material in kg, m3, and number of cement bags; water in litres.

- Export and printable report with calculation steps for site verification and procurement.

- Validation: highlight inputs that fall outside code limits (e.g., w/c too high) with recommended corrections.

Automation checks and batch control

For large projects, integrate the calculator with batch plant controls and supply chain tools:

- Automatic conversion of required cement tonnage to weekly delivery schedules.

- Stock level alerts for sand and aggregate with buffer based on Wf.

- Batch plant recipe generation including admixture dosing based on calculated water demand.

Advanced calculations: converting mass-to-volume and accounting for air content

Adjusting for entrained air

Entrained air increases concrete volume per unit mass. When designing mixes with air entrainment, compute effective mass volumes:

Mass-to-volume conversion for field batching

When batching by mass, convert required mass back to loose volumes for site measurement if scales are unavailable:

Note: Loose_bulk_density differs from compacted density; measure locally.

Frequently asked technical questions (FAQ)

Should calculators use specific gravity or bulk density?

Use bulk (bulk) density for mass-volume conversions in situ because it includes voids between particles. Specific gravity is used in laboratory absolute volume methods and for aggregate proportioning when determining void content and paste requirement.

How to adjust for moisture in sand?

- Measure moisture content by drying a representative sample.

- Convert water present to mass and deduct from mixing water required.

- Apply bulking correction to apparent sand volume if sand is damp, using empirical bulking curves.

Quality assurance, documentation, and audit trail

Every calculation must produce a machine-readable audit trail: user inputs, chosen densities, bulking values, wastage percentages, and final computed outputs. Store trial mix certificates and compressive strength test results linked to batches to validate that calculated mixes meet design strength.

References and further reading

- American Concrete Institute (ACI) — official publications and code: https://www.concrete.org

- BS EN 206: Concrete — Specification, performance, production and conformity: https://www.bsigroup.com

- IS 456: Code of Practice for Plain and Reinforced Concrete (BIS): https://www.bis.gov.in

- IS 10262: Guidelines for Concrete Mix Proportioning: https://www.bis.gov.in

- Eurocode 2: Design of concrete structures — European Commission resource: https://eurocodes.jrc.ec.europa.eu

- Portland Cement Association: technical resources on cement and concrete: https://www.cement.org

Operational checklist before executing calculated mix

- Verify actual material densities from suppliers.

- Confirm bag weight of cement used locally.

- Check recent moisture content of sand and adjust water and volume accordingly.

- Perform small-scale trial mixes to validate slump and strength.

- Ensure compliance with exposure class requirements and minimum cement content per code.

Closing technical guidance (not a title)

Concrete Ratio Calculators must be validated on every project. Pair computational outputs with laboratory tests and field inspections to ensure that theoretical quantities translate into durable, safe, and economical concrete on site. Use the formulas and workflows provided here to build a professional, effortless "123" calculator that supports procurement, batching, and structural compliance.