Tray ladder sizing requires precise calculation for safety, capacity, and regulatory compliance across installations worldwide.

Efficient calculators reduce material waste, ensure maintainability, and speed up engineering approval processes globally today.

Tray and Ladder Required Width Calculator — Efficient Sizing

Purpose and scope of a tray ladder sizing calculator

A tray ladder sizing calculator provides deterministic outputs for cable ladder width, rung spacing, and load capacity given a set of electrical and mechanical inputs. Engineers, designers, and procurement teams use these calculators to optimize cable management, reduce installation risk, and ensure compliance with electrical and building codes.

Fundamental principles governing tray ladder design

Tray ladder systems are designed to carry grouped insulated conductors, optical fiber cables, and sometimes small bundles of armored cable. Core principles include mechanical strength (static and dynamic loads), cable fill capacity (percentage-based), heat dissipation, maintainability (access and separation), and grounding/bonding continuity.

Key engineering parameters

- Cable cross-sectional area and diameter

- Total number of cables and grouping arrangements

- Tray width and rung spacing

- Tray material and span between supports

- Permitted fill percentage per standard (by cable shape and cooling requirements)

- Live load from maintenance personnel, equipment, and ice or snow where applicable

- Environmental factors: ambient temperature, UV exposure, corrosive atmosphere

Sizing algorithms and calculator logic

An efficient calculator follows a deterministic pipeline:

- Input normalization: convert cable sizes, lengths, and units to SI base units.

- Compute individual cable cross-sectional area and equivalent projected width.

- Aggregate the required horizontal area for the cable group plus service space for heat dissipation and maintenance.

- Apply fill-factor rules (per standard or project requirement) to derive minimum tray width.

- Check mechanical viability: span, lamination, material strength, and deflection limits.

- Output recommended tray ladder width, rung spacing, support spacing, and estimated material weight.

Data validation and normalization

- Unit checks (mm vs in, mm2 vs AWG): normalize to millimeters and mm2 for internal calculations.

- Sanity checks for cable counts and sizes to prevent unrealistic trays (e.g., >95% fill).

- Fallback defaults for missing data: typical conductor diameters, insulation thickness, and single-cable projected width.

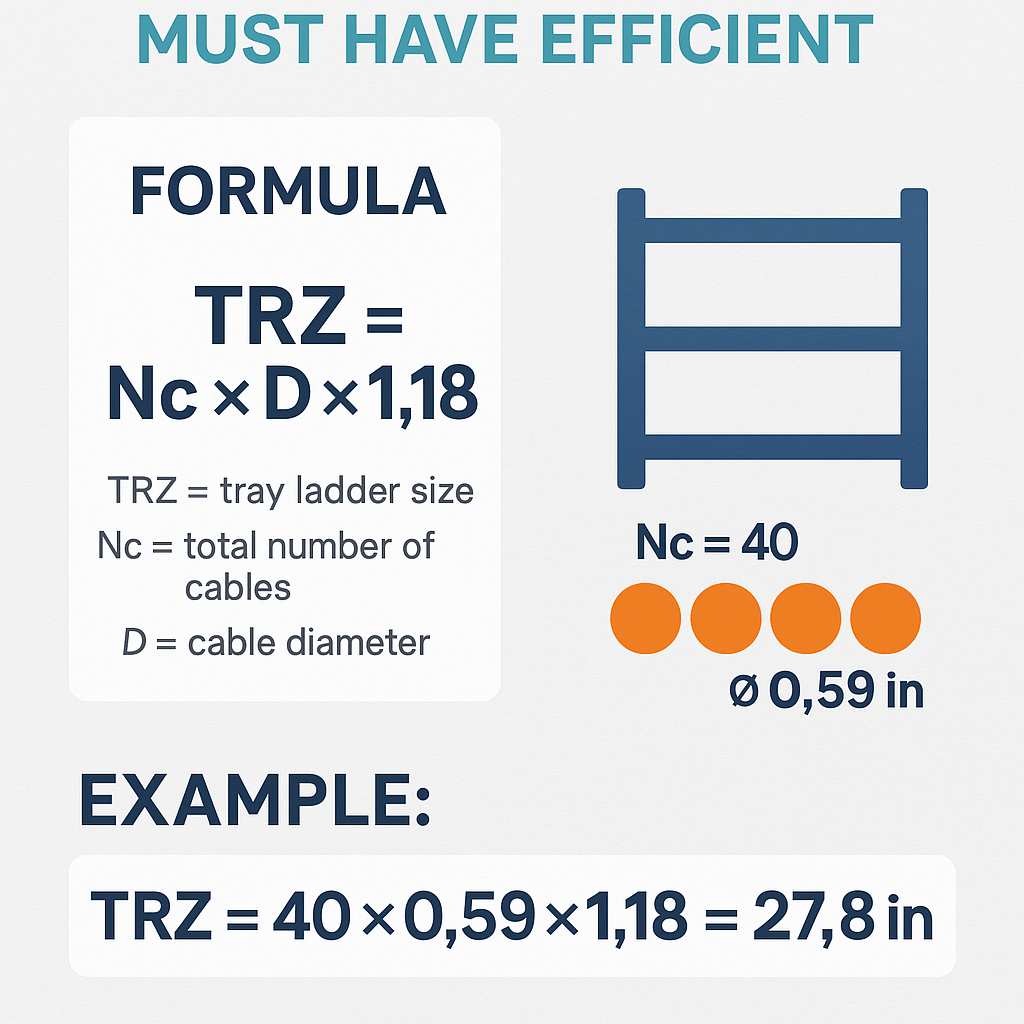

Formulas and variable explanations

Below are the core formulas an efficient calculator must implement. Each formula is expressed in plain HTML-friendly text. Typical values follow each variable definition.

1. Cross-sectional area of a round conductor (insulated cable approximate):

Ac = π × (d / 2)2

- Ac = cross-sectional area (mm2)

- d = overall insulated cable diameter (mm). Typical values: 8 mm (small control cable), 20 mm (large power cable), 40 mm (multi-core armored).

2. Projected width per cable (approximate when laying side-by-side):

- w = projected width contribution of each cable (mm)

- k = packing coefficient (0.9–1.1). Use 1.0 for conservative design.

3. Total required horizontal width (sum of projected widths):

Wreq = Σ wi + Sservice

- Wreq = required internal tray width (mm)

- Σ wi = sum of projected widths of individual cables (mm)

- Sservice = service allowance for cooling and future reserves (mm). Typical: 10–25% of Σ wi or minimum 50 mm.

4. Tray width based on fill factor:

Wtray ≥ Wreq / Ffill

- Wtray = chosen internal tray width (mm), select nearest standard size.

- Ffill = allowable fill fraction (decimal). Typical: 0.5 (50%) for power cables, 0.75 (75%) for small telecommunication cables unless thermal considerations force lower fill.

5. Mechanical deflection check for ladder rungs beam:

δ = (5 × wL × L4) / (384 × E × I)

- δ = maximum midspan deflection (mm)

- wL = uniform load per unit length (N/mm) from cables and tray self-weight

- L = span between supports (mm)

- E = Young's modulus of tray material (N/mm2; steel ≈ 210 000 N/mm2)

- I = second moment of area for the rung/side rail (mm4)

- Acceptable δ ≤ L/200 for heavy-loaded trays, L/100 for light service (project dependent).

6. Load per unit length from cables (static):

wL = (Σ massi × g) / Lcover

- massi = mass per length of cable i (kg/m). Typical: 0.05–0.5 kg/m depending on size and armor.

- g = 9.81 m/s2 (convert units such that wL is N/mm or N/m depending on formula consistency)

- Lcover = 1 m (if calculating per metre of tray)

7. Maximum number of cables by area fill (alternative area-based method):

- Nmax = maximum number of cables of type considered

- Wtray = internal tray width (mm)

- Dtray = usable tray depth (mm). Typical depth: 50 mm, 75 mm, 100 mm, 150 mm

- Acproj = projected cross-sectional area of an insulated cable (mm2) — for rectangular packing use empirical coefficient.

Typical values and lookup tables

Use the following tables as inputs or defaults in a calculator. Standard tray widths are widely available; choose the smallest that satisfies Wtray ≥ computed requirement.

| Cable type | Typical insulated diameter (mm) | Mass per length (kg/m) | Projected area Ac (mm²) |

|---|---|---|---|

| Control/Instrumentation 4 mm² | 4.5 | 0.02 | 15.9 |

| Power 16 mm² | 8.5 | 0.07 | 56.7 |

| Power 95 mm² | 16.0 | 0.25 | 201.1 |

| Armored multiconductor 3-core 240 mm² | 36.0 | 1.10 | 1017.9 |

| Fiber optic loose tube (12-fibres) | 6.0 | 0.03 | 28.3 |

| Standard tray internal widths (mm) | Common depths (mm) | Typical rung spacing (mm) |

|---|---|---|

| 100, 150, 200, 300, 400, 500, 600, 800, 1000 | 25, 50, 75, 100, 150 | 200, 300, 400 |

Real-case Example 1: Industrial plant power feeder bundle

Project brief: A three-phase power feeder run contains 4 × 95 mm² XLPE insulated power cables and 1 × 16 mm² earth conductor. The run must be contained in a ladder tray with 1000 mm support spans and a steel ladder specified. Determine minimum tray width and support spacing verification.

Inputs

- 4 × 95 mm² power cables: diameter d = 16.0 mm, mass ≈ 0.25 kg/m each

- 1 × 16 mm² earth: diameter d = 8.5 mm, mass ≈ 0.07 kg/m

- Service allowance Sservice = 20% of cable stack width

- Fill factor Ffill = 0.50 (50%) recommended for large power cables per thermal and ventilation guidance

- Span L = 1000 mm; material: structural steel E = 210 000 N/mm2

- Rung/side rail geometry: assume available I = 8 × 106 mm4 (typical ladder side rail section — verify with manufacturer)

Step-by-step calculations

Each 95 mm² cable: w = d = 16.0 mm → 4 cables contribute 4 × 16.0 = 64.0 mm

Earth: w = 8.5 mm → total Σ wi = 64.0 + 8.5 = 72.5 mm

3. Required internal width Wreq = Σ wi + Sservice = 72.5 + 14.5 = 87.0 mm

Select nearest standard internal tray width: 200 mm

5. Mechanical load per metre:

6. Deflection δ (use formula δ = 5 wL L4 / (384 E I)): convert L = 1000 mm

δ = (5 × 0.01049 × 10004) / (384 × 210000 × 8×106)

Compute numerator: 5 × 0.01049 × 1012 = 5 × 0.01049 × 1e12 = 5.245 × 1e10 ≈ 5.245e10

δ ≈ 5.245e10 / 6.4512e14 ≈ 8.13e-5 mm ≈ 0.0000813 mm (negligible)

Deflection limit L/200 = 1000/200 = 5 mm. The computed δ is far below limit; structural capacity is adequate.

Final recommendation: select 200 mm internal width ladder tray, depth 50 mm or 75 mm depending on fixing and impact requirements. Support spacing can remain 1 m, verify manufacturer maximum span tables for chosen ladder profile.

Real-case Example 2: Telecommunications and mixed services on cable ladder

Project brief: A telecommunications corridor requires bundling 120 × 12-fibre fiber cables (diameter 6.0 mm) and 30 × 4 mm² instrumentation cables (diameter 4.5 mm) in the same ladder. Thermal issues are minimal but future expansion and maintainability mandate a conservative service allowance. Determine tray size and expected cable count capacity.

Inputs

- 120 fiber cables (d=6.0 mm), mass ≈ 0.03 kg/m each

- 30 instrument cables (d=4.5 mm), mass ≈ 0.02 kg/m each

- Sservice = 25% (reserve for future cables and separation)

- Ffill = 0.75 (75%) for small cables

- Standard depths: assess 100 mm and 150 mm

Step-by-step calculations

1. Projected widths:

Σ wi = 720 + 135 = 855 mm

Select nearest standard tray internal width: 1500 mm (or use two 750 mm trays in parallel if standardization preferable)

Estimate Acproj per 12-fibre loose tube = π × (6/2)2 = π × 32 = 28.27 mm2

Volume area available = 1500 × 100 × 0.75 = 112500 mm2

Even with Dtray = 50 mm, available = 1500 × 50 × 0.75 = 56250 mm2, Nmax ≈ 1989 cables. Therefore depth 50 mm would be sufficient from pure area sense; however, maintenance and separation recommend Dtray 100 mm.

6. Mechanical check (mass and deflection): total mass per m = (120 × 0.03) + (30 × 0.02) = 3.6 + 0.6 = 4.2 kg/m

For span L = 1000 mm and assume ladder I = 5×106 mm4:

δ ≈ (5 × 0.0412 × 1e12) / (384 × 210000 × 5e6) ≈ numerator 2.06e11; denominator ≈ 4.032e14; δ ≈ 0.00051 mm

Acceptable deflection L/200 = 5 mm → structural OK. However, verify dynamic loads and possible grouping weight concentration.

Final recommendation: use a 1500 mm internal width ladder tray with 100 mm usable depth or two parallel 750 mm trays separated by divider rails. Use maintainable routing for fiber (separate inner lanes, bend radii control). Provide cable separation racks for future expansion.

Standards, normative references, and authoritative links

Designs must reference applicable international and national standards for cable tray systems, safety, and electrical installations. Common references include:

- IEC 61537: Cable management — cable trays and cable ladder systems (http://www.iec.ch)

- NFPA 70 (NEC) Article 392: Cable Trays — installation details and fill guidance (https://www.nfpa.org)

- NEMA VE 1: Sheet Steel Cable Tray Systems (https://www.nema.org)

- BS EN 61537: British/European adoption of IEC 61537 (https://shop.bsigroup.com)

- Manufacturer datasheets and load/span tables (consult specific sectional properties)

Always cross-check project-specific electrical codes and local amendments before final selection.

Best practices to make a calculator efficient and reliable

- Pre-load manufacturer span and deflection tables — avoid purely theoretical I estimations where available.

- Implement unit conversion and round-trip traceability of inputs and outputs for accountability.

- Include code-based defaults but allow overrides for project-specific fill factors, derating, or separation rules.

- Provide warnings when inputs imply thermal derating or exceed code limits (e.g., fill > 50% for large power).

- Allow scenario comparison: single wide tray versus multiple narrower trays with divider rails.

- Incorporate future-expansion sliders to show footprint vs. spare capacity trade-offs.

- Ensure accessible export of calculation reports with assumptions, normative references, and manufacturer part numbers.

Validation, testing, and UX considerations for calculators

Practical UX and testing reduce engineering errors and speed approvals. Key items:

- Validation dataset: include representative industrial, commercial, and telecom bundle examples that exercise extremes.

- Edge-case handling: very high fill percentages, mixed conductor shapes, and heavy armored cables.

- Interactive feedback: immediate fill percentage, recommended trays, and visual diagrams of cable placement.

- Fallback guidance: when results exceed catalog products, provide staged solutions (parallel trays, increased depth, or segregated racks).

- Regulatory compliance flags: explicit checkboxes for NEC/IEC/NEMA rules and localized code choices.

Installation and operational considerations not to be overlooked

- Maintain minimum separation distances for different voltage classes when required by code.

- Bond and ground trays per electrical code to provide a continuous path for fault currents.

- Consider cable routing at bends: use bend radius controls and reinforced sections to avoid cable chafing.

- Provide drip guards, covers, and cable ties designed for the environmental conditions (UV-resistant, halogen-free where required).

- Plan access points for future cable additions, label trays by run identifier, and provide cable schedules in documentation.

Advanced features for professional calculators

Advanced calculators for engineering teams can include:

- Thermal interaction modeling: calculate de-rating for current-carrying conductors in densely packed trays (implement IEC/NFPA thermal derating curves).

- 3D layout export for BIM integration to detect clashes and generate procurement lists.

- Material cost estimator and lifecycle CO2 emissions estimator for sustainability-conscious projects.

- Automated compliance reporting referencing specific clauses in IEC/NFPA/British standards.

- API endpoints for integration with ERP and procurement systems for BOM generation.

Maintenance, documentation, and traceability

Each sizing decision must be recorded with input assumptions, versioned standards used, and sign-off by responsible engineers. Recommended documentation contents:

- Input dataset: cable lists, diameters, masses, and grouping rules.

- Calculation ledger: intermediate steps, formulas, and rounding rules.

- Selected product details: manufacturer ladder profile, part numbers, and vendor load tables.

- Inspection and maintenance schedule.

- Traceable sign-off with date, engineer ID, and project version.

Common pitfalls and mitigation strategies

- Underestimating service allowance — consequence: rework or overloaded trays. Mitigation: include mandatory minimum reserve (50 mm or 10%).

- Ignoring thermal derating for power cables — consequence: overheating and insulation damage. Mitigation: force derating checks for power cables >35 mm² or grouped installations.

- Using insufficient mechanical span data — consequence: excessive sag or failure. Mitigation: use manufacturer span tables and conservative deflection limits.

- Failure to separate incompatible services — consequence: electromagnetic interference or code violations. Mitigation: implement separation rules and divider options in the calculator.

References and further reading

- IEC 61537 — Cable management — Cable tray systems and cable ladder systems (purchase or consult national body)

- NFPA 70®: National Electrical Code® (NEC®) — Article 392: Cable Trays — https://www.nfpa.org/NEC

- NEMA VE 1 — Guidelines for cable tray systems — https://www.nema.org/

- BS EN 61537: Cable management — https://shop.bsigroup.com

- Manufacturer span and load tables (typical examples: Legrand, Cablofil, Thomas & Betts) — consult vendor sites for datasheets

Final guidance for practitioners

An effective tray ladder sizing calculator combines robust mechanical checks, conservative thermal/fill rules, and practical installation constraints. For critical feeders or densely packed communications runs, always couple the calculator output with manufacturer verification and an on-site review before procurement and installation.