This article explains technical methods to calculate UPS capacity for various loads accurately and consistently.

Engineers will find formulas, tables, examples, normative references, and practical sizing workflows here for design.

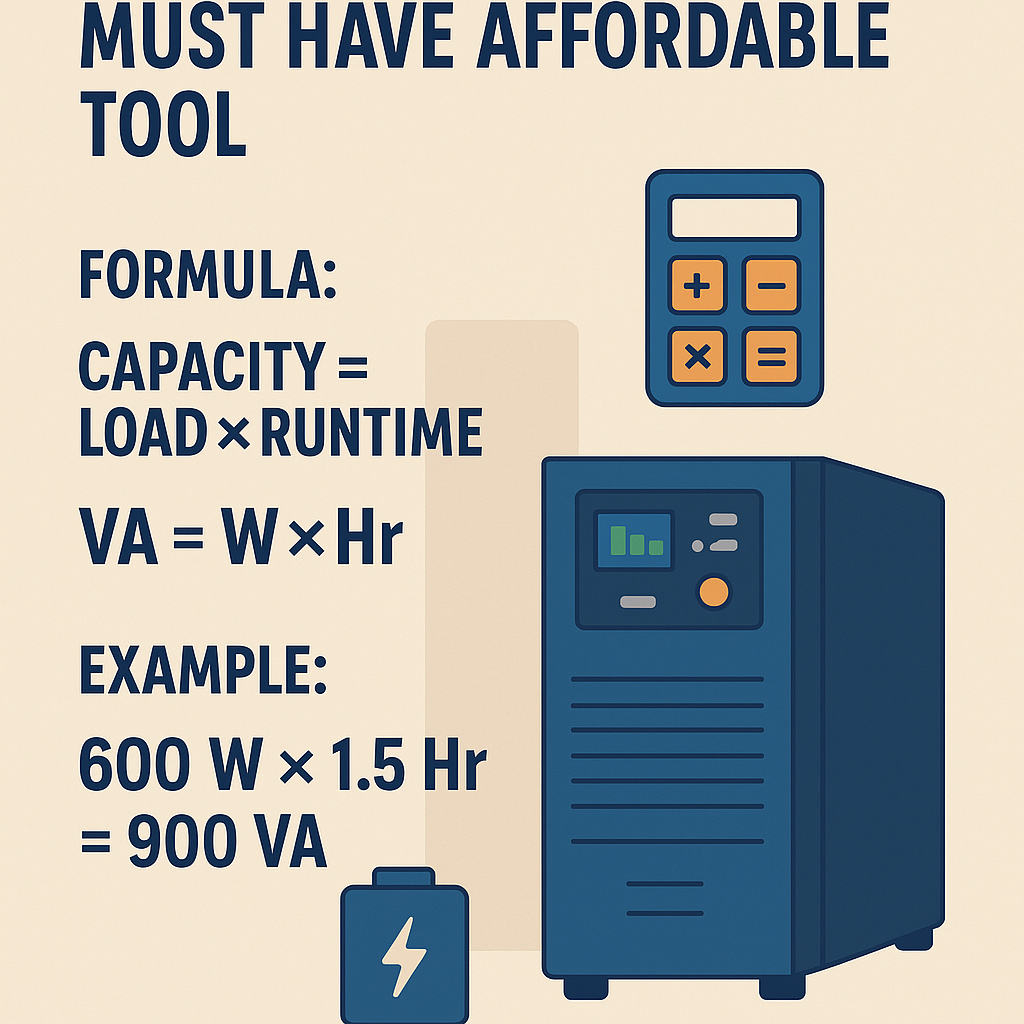

UPS Capacity & Battery Sizing Calculator — Practical Affordable Tool

UPS Sizing Fundamentals and Objectives

Sizing a UPS (Uninterruptible Power Supply) is an engineering exercise that balances electrical load, autonomy (runtime), reliability, and cost. The primary objective is to specify an inverter/rectifier and battery system that supplies critical loads under defined conditions (voltage, frequency, harmonic content, and emergency duration) while conforming to standards and site constraints.

Primary design outputs

- Required apparent power rating in volt-amperes (VA or kVA).

- Required active power capability in watts (W or kW) and overload margin.

- Battery DC voltage and ampere-hour (Ah) capacity to achieve demanded runtime.

- Configuration details: number of strings, series/parallel battery arrangement, and UPS topology (online double-conversion, line-interactive, or standby).

- Efficiency, ambient derating, and thermal considerations.

Key parameters and definitions

Precise definitions are essential to avoid mis-sizing. Use nameplate and in-situ measurements where possible rather than vendor marketing numbers.

Essential terms

- Active power (P): Real power consumed by loads measured in watts (W or kW).

- Apparent power (S): Product of RMS voltage and RMS current, measured in volt-amperes (VA or kVA).

- Power factor (pf): pf = P / S (dimensionless). Typical loads have pf from 0.6 to 1.0.

- Efficiency (η): Ratio of output power to input power of the UPS (typically 90–97% depending on loading and topology).

- Inverter efficiency (ηinv): Efficiency of DC-to-AC conversion, used when computing DC battery energy requirements.

- Depth of discharge (DOD): Fraction of battery capacity usable without harming cycle life (typical design DOD 50–80% for VRLA and flooded lead-acid; lithium-ion often 80–90%).

- Battery temperature derating: Capacity decreases with temperature deviations from manufacturer’s reference (often 25 °C).

Fundamental sizing formulas

Presenting clear formulas using HTML text. Each formula is followed by variable definitions and typical values.

Apparent power (VA) required

Variables and typical values:

- P: Total active load in watts (W). Typical office rack: 1,500–5,000 W. Small data room: 10,000–30,000 W.

- pf: Load power factor (dimensionless). Typical pf: 0.8 to 0.95 for mixed IT loads; motors may be 0.6–0.9.

UPS nominal kVA selection with margin

Where Safety factor typically = 1.1 to 1.25 (10–25% headroom for growth and harmonics).

Battery energy calculation for required runtime

For most practical UPS sizing, combine inverter and rectifier efficiencies into overall UPS efficiency η (dimensionless):

Variables and typical values:

- Pout: Output active power demanded during outage (W).

- Truntime: Desired autonomy in hours (h). Example: 0.25 h (15 minutes), 1 h, 4 h.

- η: End-to-end energy efficiency from battery DC to load AC including inverter and conversion losses. Typical ηinv: 0.90–0.96.

- E.g., for a 3 kW load and 0.9 efficiency, battery energy required for 15 minutes = (3000 W × 0.25 h) / 0.9 = 833 Wh.

Converting Wh to battery Ah at a nominal DC voltage

Variables and typical values:

- Battery nominal voltage Vdc: Typical UPS battery banks use 24 V, 48 V (most small to medium UPS), or 110–400 V strings in large systems. Common small UPS: 48 V DC.

- DOD: Usable fraction of nominal capacity. Typical design DOD: 0.5 (50%) for VRLA, 0.8 (80%) for Li-ion.

- Example: For 833 Wh required, at 48 V and DOD 0.5: Ah = 833 / 48 / 0.5 = 34.7 Ah (choose standard battery 40 Ah).

Accounting for temperature and aging derating

Typical aging_loss: 0.1 (10%) after few years; temp_loss: 0.1 per ±10 °C from reference. Use conservative margins for mission-critical installations.

| Parameter | Typical Range | Design Value (conservative) |

|---|---|---|

| Power factor (pf) | 0.6 – 0.95 | 0.9 for IT loads, 0.8 for mixed loads |

| Inverter efficiency (ηinv) | 90% – 97% | 0.92 |

| Battery DOD (lead-acid) | 30% – 80% | 50% |

| Battery DOD (Li-ion) | 70% – 95% | 80% |

| Safety factor for growth | 1.05 – 1.3 | 1.15 (15% growth) |

| Ambient temperature adjustment | ±10% per 10 °C deviation | Include +10% capacity for <20 °C design |

Worked examples — real cases with complete calculations

Case Study 1: Single-rack data center — 3 kW load, 15-minute runtime

Scenario: A private cloud server rack consumes 3,000 W continuous. Requirement: 15 minutes of runtime for orderly shutdown or transfer to generator. UPS topology: online double-conversion. Battery choice: 48 V VRLA string.

- Compute apparent power S:

P = 3,000 W. Assume pf = 0.95 (typical server loads).

S = P / pf = 3,000 / 0.95 = 3,157.9 VA ≈ 3.16 kVA.

- Apply safety margin (15% growth):

UPS rating required = S × 1.15 = 3,157.9 × 1.15 = 3,631.6 VA ≈ 3.63 kVA.

Select commercially available UPS: choose at least 4 kVA (to provide some headroom and standard module size).

- Compute battery energy required:

Desired runtime Truntime = 15 minutes = 0.25 h.

Assume end-to-end efficiency η = 0.92.

Battery energy (Wh) = (P × Truntime) / η = (3,000 × 0.25) / 0.92 = 813.0 Wh (rounded).

- Convert to battery Ah for 48 V nominal:

Design DOD for VRLA = 0.5 (50%).

Ah_required = Battery energy (Wh) / Vdc / DOD = 813 / 48 / 0.5 = 33.88 Ah.

Select a standard 48 V battery string composed of 4 × 12 V, 40 Ah VRLA batteries in series → bank = 48 V, 40 Ah.

- Adjust for temperature and aging:

Assume aging and temp derating total 15% (conservative). Effective Ah needed = 33.88 / (1 − 0.15) = 39.86 Ah.

40 Ah bank is acceptable and provides slight margin.

- Other considerations:

- Check battery discharge curve — 15 minutes is a high-rate discharge; verify manufacturer’s Ah rating at 15-minute discharge (C/4 rate for a 1-hour rating, but 15-minute is higher current and effective capacity reduces).

- Confirm inverter maximum continuous current at selected UPS rating and ensure battery cable and fuses sized accordingly.

Case Study 1 — summary and final selection

- Design active load: 3,000 W; chosen UPS: 4 kVA (online double-conversion).

- Battery bank: 4 × 12 V, 40 Ah VRLA in series → 48 V, 40 Ah (estimated runtime ≥ 15 minutes at 3 kW accounting for derating).

- Verify with battery manufacturer discharge curves and perform site acceptance test under load.

Case Study 2: Small office — 20 kW critical load, 1 hour runtime, 400 V DC battery bus

Scenario: A financial office with mixed IT and lighting critical loads totals 20,000 W. Required autonomy: 1 hour to maintain operations until generator start or safe shutdown. UPS architecture: modular string of 20 kW rated modules; battery architecture uses a 240 V or 384 V nominal DC bus depending on vendor. Here we choose a 480 V DC battery bus (typical for larger UPS).

- Compute apparent power S:

P = 20,000 W. Mixed loads pf assumed = 0.85.

S = 20,000 / 0.85 = 23,529 VA ≈ 23.53 kVA.

- Choose UPS rating with growth margin:

Apply safety factor 1.15 → required kVA = 23.53 × 1.15 = 27.06 kVA.

Select commercial UPS capacity: choose 30 kVA (or two 15 kVA modules in parallel for redundancy).

- Compute battery energy required:

Truntime = 1 h. Assume η (DC→AC) = 0.94.

Battery energy (Wh) = (P × Truntime) / η = 20,000 / 0.94 = 21,276 Wh ≈ 21.28 kWh.

- Convert Wh to Ah at nominal DC bus (assume 480 V nominal):

Ah_required = 21,276 Wh / 480 V / DOD.

Assume Li-ion with DOD = 0.8.

Ah_required = 21,276 / 480 / 0.8 = 55.31 Ah.

- Determine battery string composition:

Li-ion modules commonly come in 3.2 V nominal cells; typical commercial modules assembled to reach 480 V with integrated BMS. For lead-acid alternative, 40 × 12 V in series = 480 V nominal with appropriate Ah rating.

Choose modules to total ≥ 55.31 Ah, then apply aging/temp derating (10–20%). Adjusted Ah = 55.31 / (1 − 0.15) = 65.07 Ah. Choose 70 Ah modular battery bank at 480 V.

- Check DC ripple and charger sizing: Charger must replenish battery and float at correct current; ensure rectifier/charger size allows recharge within required window.

Case Study 2 — summary and final selection

- Design active load: 20 kW; chosen UPS: 30 kVA or modular parallel modules for redundancy.

- Battery bank: 480 V nominal, ~70 Ah usable bank (Li-ion modules sized to provide ≥21.3 kWh usable energy accounting for DOD and derating).

- Confirm with vendor battery discharge performance and rack-level protection.

| Example Load | P (W) | pf | S (kVA) | UPS kVA selected | Battery bank |

|---|---|---|---|---|---|

| Single rack (Case 1) | 3,000 | 0.95 | 3.16 | 4.0 kVA | 48 V, 40 Ah VRLA (4 × 12 V × 40 Ah) |

| Small office (Case 2) | 20,000 | 0.85 | 23.53 | 30 kVA (modular) | 480 V, ~70 Ah Li-ion bank (~21.3 kWh usable) |

Common lookup tables for quick design

Use lookup tables as starting points; always validate with detailed calculations and vendor performance curves.

| Load (W) | pf | kVA required (no margin) | kVA with 15% margin |

|---|---|---|---|

| 1,000 | 0.9 | 1.11 | 1.28 |

| 3,000 | 0.95 | 3.16 | 3.63 |

| 5,000 | 0.9 | 5.56 | 6.39 |

| 10,000 | 0.85 | 11.76 | 13.52 |

| 20,000 | 0.85 | 23.53 | 27.06 |

| 50,000 | 0.9 | 55.56 | 63.89 |

| Battery bank voltage | Typical module arrangement | Common use |

|---|---|---|

| 48 V | 4 × 12 V series | Small UPS, telecom closets |

| 240 V | 20 × 12 V series or modular | Medium UPS systems |

| 480 V | 40 × 12 V series or high-voltage string | Large UPS for data centers |

| DC bus 400–600 V | High-voltage Li-ion modules | Large installations with reduced DC current |

Practical workflow for UPS capacity calculation

- Inventory loads: measure or sum nameplate active powers and classify critical vs non-critical.

- Estimate or measure power factor of each load; use harmonics-aware meters if non-linear loads present.

- Sum active power P_total and compute S_total = P_total / pf_weighted.

- Apply safety/growth margin (10–25%) and select vendor UPS modules accordingly.

- Define required runtime; compute battery energy and convert to Ah at chosen DC bus voltage including DOD and derating.

- Verify physical constraints: battery room HVAC, battery ventilation, cable ampacity, and breaker sizing.

- Check compliance with standards (see references) and perform factory acceptance tests and site acceptance tests under representative loads.

Normative references and authoritative resources

Design and selection should reference international and national standards, and manufacturer guidance:

- IEC 62040 series — Uninterruptible Power Systems (UPS) — performance and test methods. See IEC for details: https://www.iec.ch

- NFPA 110 — Standard for Emergency and Standby Power Systems — requirements for standby power and testing: https://www.nfpa.org/

- IEEE 446 — Emergency and standby power systems for industrial and commercial power systems (Red Book) — recommended practice: https://standards.ieee.org/

- Battery standards and guidelines: IEC 60896 (stationary lead-acid batteries) and IEC 62619 (Li-ion safety). See IEC documentation.

- Manufacturer technical guides: APC/Schneider Electric UPS selection and battery runtime calculators: https://www.se.com/ and APC by Schneider Electric technical resources: https://www.apc.com/

- Eaton and Vertiv selection guides and runtime calculators provide vendor-specific performance curves: https://www.eaton.com/ and https://www.vertiv.com/

Practical selection, commissioning, and testing tips

- Always validate through a site load step test or simulated outage prior to commissioning.

- Request battery manufacturer discharge curves at the specific rate (15 min, 30 min, 1 hr) — Ah rating varies with discharge rate.

- Consider parallel UPS modules for N+1 redundancy; include internal imbalance and load-sharing capability in sizing.

- Account for harmonic currents: non-linear loads increase heating and can affect UPS derating.

- Plan battery maintenance space, ventilation for VRLA and flooded systems, and BMS integration for Li-ion.

Cost vs reliability trade-offs and optimization

Budget constraints often drive selection between oversized UPS with low battery capacity versus smaller UPS with extended battery banks. Use a cost-per-kWh and cost-per-Ah analysis combined with reliability needs.

Decision criteria

- Criticality of loads (financial loss per minute of outage).

- Availability of generator backup and generator start time.

- Site constraints: footprint, weight limits, thermal management.

- Maintenance frequency and lifecycle cost (Li-ion often higher upfront, lower lifecycle cost and smaller footprint).

Final recommendations and best practices

- Use measured load data when available; estimate conservatively when not.

- Document all assumptions: pf, efficiency, DOD, ambient temperature, and aging factors.

- Engage battery and UPS manufacturers early to match performance curves and warranties.

- Include capacity for foreseeable growth and emergency reconfiguration scenarios.

- Ensure compliance with local electrical codes (e.g., NEC in the USA) and fire/safety standards.

References

- IEC 62040 series — Uninterruptible power systems (UPS). International Electrotechnical Commission. https://www.iec.ch/

- NFPA 110 — Standard for Emergency and Standby Power Systems. National Fire Protection Association. https://www.nfpa.org/

- IEEE Std 446 — Recommended Practice for Emergency and Standby Power Systems for Industrial and Commercial Applications. IEEE Xplore. https://standards.ieee.org/

- Schneider Electric — UPS selection and design guides. https://www.se.com/

- APC by Schneider Electric — UPS runtime and selection tools. https://www.apc.com/

- Eaton whitepapers on UPS sizing and battery selection. https://www.eaton.com/

- Vertiv technical resources on UPS and battery architectures. https://www.vertiv.com/

By following the formulas, tables, and workflows provided, engineers can size UPS systems that meet operational objectives while ensuring compliance with industry norms and optimizing cost and reliability.