This article explains transformer cable calculators aligned with NEC requirements for safe, affordable installations everywhere.

Engineered methods ensure conductor sizing, ampacity, voltage drop, short‑circuit, and cost targets meet codes requirements.

Transformer Feeder Cable Sizing & Voltage‑Drop Calculator (NEC‑oriented)

Regulatory and Technical Scope for Transformer Cable Calculators

Transformer cable calculators must embed NEC (NFPA 70) principles, engineering best practices, and economic optimization. These calculators should reflect conductor ampacity tables, adjustment and correction factors, transformer rules, grounding and bonding requirements, voltage‑drop limits, and fault‑current capabilities while remaining user friendly and affordable for designers and contractors.

Essential NEC References and Standards

- NFPA 70 (National Electrical Code): conductor ampacity, overcurrent protection, transformer rules (see Articles 310, 240, 450, 250).

- IEEE standards relevant to transformer inrush and short‑circuit (e.g., IEEE Std 141, IEEE Std C57 series).

- IEC 60287 for cable current‑rating calculations (useful for international contexts).

- NEMA/NEC tables for conductor sizes, insulation types, and practical installation constraints.

Authoritative links: NFPA NEC, IEEE Standards, NEMA, IEC.

Calculator Requirements: What a Transformer Cable Calculator Must Include

To be compliant and useful a calculator should perform:

- Conductor ampacity selection per NEC ampacity tables (adjusted for temperature and grouping).

- Voltage‑drop computation for feeders and branch circuits (single‑ and three‑phase).

- Continuous load handling rules (125% factor for continuous loads per NEC 210.19(A)(1), 215.2(A)(1)).

- Short‑circuit and fault‑current evaluation to ensure conductor mechanical strength and protective device coordination.

- Overcurrent protective device (OCPD) sizing and application of NEC rules for transformer's primary and secondary overcurrent protection (NEC 450.3, 240).

- Grounding conductor sizing and equipment grounding per NEC 250.102 and 250.66.

- Ambient temperature, conduit fill, and insulation correction/derating (NEC 310.15(B)).

- Cost optimization module that balances conductor size vs cost and energy losses.

UX and Input Parameters

- Transformer kVA, primary/secondary nominal voltage, phase (single/three‑phase), and power factor.

- Load type: continuous, non‑continuous, motor starting characteristics, harmonic content.

- Conductor material: copper or aluminum; insulation type: THHN, XHHW‑2, USE, etc.

- Installation: conduit interior, duct bank, direct burial, ambient temperature, and number of current‑carrying conductors.

- Run length and acceptable voltage‑drop percentage (commonly 3% for branch circuits, 5% combined for feeder+branch).

- Available short‑circuit current at point of connection.

- Unit costs for cable and installation labor for affordability analysis.

Key Formulas and Variable Explanations

All formulas below use plain HTML notation. After each formula, variables are defined and typical values are provided.

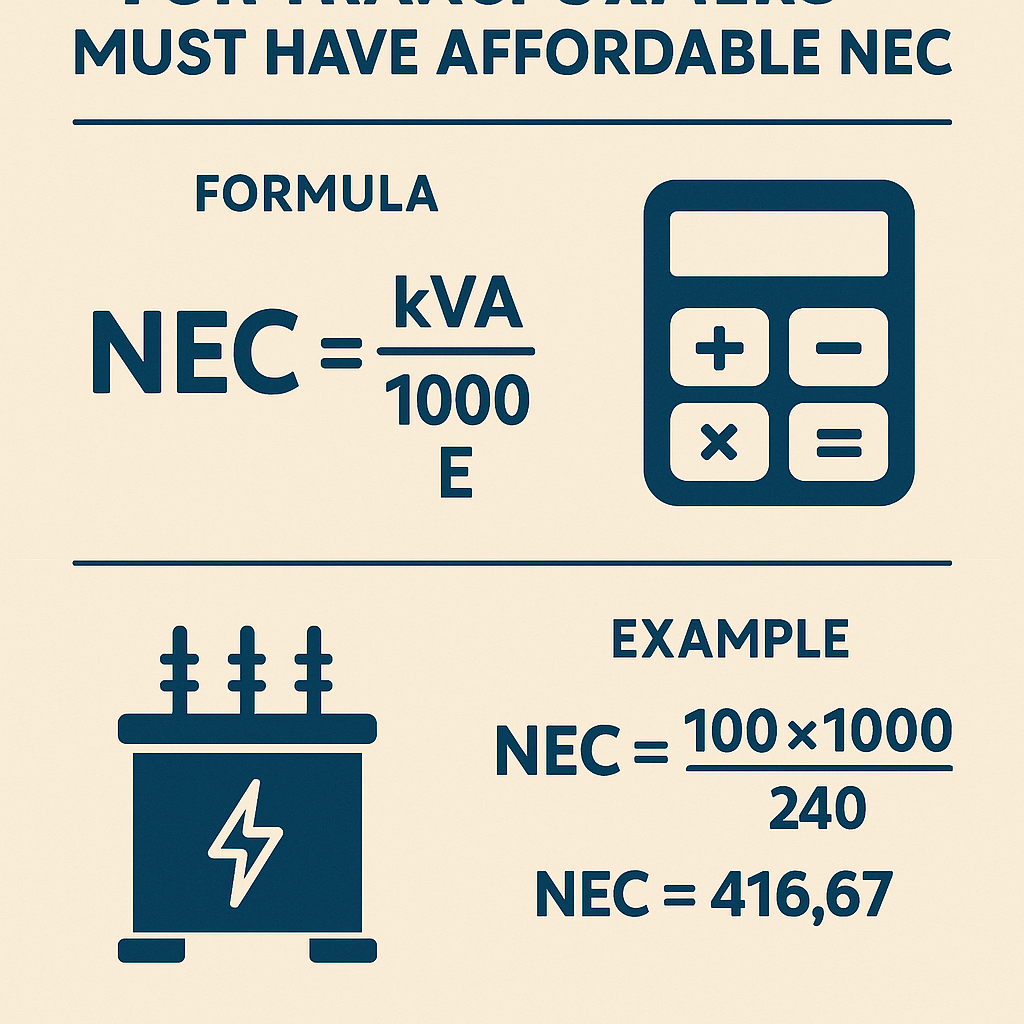

1) Transformer Full‑Load Current (single‑phase)

Variables:

- I = full‑load current (A)

- kVA = transformer rated kilovolt‑amps (kVA)

- V = line voltage (V), single‑phase voltage line‑to‑line

2) Transformer Full‑Load Current (three‑phase)

Variables:

- I = full‑load current (A)

- kVA = transformer rated kilovolt‑amps (kVA)

- V = line voltage (V), line‑to‑line

- √3 ≈ 1.732

3) Voltage Drop (three‑phase)

Variables:

- VD% = voltage drop percentage

- I = current (A)

- R = conductor resistance (Ω/km or Ω/1000 m depending units)

- L = one‑way length (m or km matching R's units)

- V = system voltage (V)

4) Continuous Load Conductor Sizing

Variables:

- Continuous load current = load current expected to run continuously (≥3 hours)

5) OCPD Sizing and NEC Tap Rules

Calculator should ensure OCPD selection follows NEC maximums: for conductors, OCPD ≤ 800% of transformer secondary if allowed by specific rules, and more commonly sized at 125% for continuous heating loads; refer to NEC 240 and 450 for transformer protection details.

Conductor Ampacity and Common Values

Provide ampacity reference values for common conductors under typical conditions (insulation THHN/THWN/ XHHW‑2, 75°C column unless terminations rated otherwise). These tables are representative; always consult the current NEC and manufacturer data.

| AWG/kcmil | Material | Approx Area (mm²) | Typical Ampacity (A) @ 75°C | Resistance (Ω/1000m) |

|---|---|---|---|---|

| 14 AWG | Copper | 2.08 | 20 | 8.286 |

| 6 AWG | Copper | 13.3 | 65 | 0.395 |

| 3/0 AWG | Copper | 85.0 | 200 | 0.0505 |

| 350 kcmil | Copper | 177 | 280 | 0.0208 |

| 750 kcmil | Copper | 380 | 420 | 0.0104 |

| 250 kcmil | Aluminum | 127 | 205 | 0.0328 |

| 500 kcmil | Aluminum | 254 | 305 | 0.0182 |

Calculator Design: Algorithmic Steps

- Input collection: transformer rating, voltages, run length, cable type, ambient temperature, installation method, load characteristics, available fault current, and cost rates.

- Calculate full‑load currents using formulas above (single‑ or three‑phase).

- Apply continuous load factor (if applicable) and determine required conductor ampacity (×1.25 for continuous loads per NEC).

- Apply correction factors: ambient temperature correction, conductor count (grouping), conductor insulation correction; use NEC adjustment tables (e.g., 310.15(B)(2)(a) and 310.15(B)(3)(a) depending on edition).

- Select the smallest standard conductor meeting corrected ampacity and termination rating.

- Compute voltage drop for selected conductor and verify it stays within project limits; if not, increase conductor size iteratively until VD acceptable.

- Verify short‑circuit withstand: compute available fault current at terminations and ensure conductor mechanical limits and protective device let‑through energy are acceptable.

- Output OCPD sizing suggestion, ground conductor size, and bill‑of‑materials with cost estimate and comparison options (copper vs aluminum, different insulation types).

Detailed Practical Examples

Example 1 — Three‑Phase 150 kVA, 480 V Transformer Feeder

Problem statement: Size feeder conductors from a pad‑mounted transformer secondary (150 kVA, 480 V three‑phase) to a motor control center 50 meters away. Load is continuous at 80% of transformer's rated capacity. Acceptable voltage drop for feeder is 3%. Conductor options: copper THHN (75°C column). Ambient temperature 30°C. There are three current‑carrying phase conductors plus one neutral in the conduit.

Step 1 — Full‑load current calculation: I_FL = (1000 × 150) / (√3 × 480) = (150000) / (831.384) ≈ 180.4 A.

Step 2 — Continuous load current: Continuous load = 0.8 × 180.4 ≈ 144.3 A. Required conductor ampacity = 1.25 × 144.3 = 180.4 A. Note: Because the load is continuous at 80% of transformer, after multiplying by 1.25 we return to the transformer's full‑load current. NEC rule requires conductor ampacity to be at least 125% of continuous load.

Step 3 — Adjustment factors: - Ambient 30°C: THHN ampacity table at 75°C remains valid (standard tables assume 30°C ambient in many tables; minor correction not required for modest elevations). - Number of current‑carrying conductors: three phase conductors in conduit + neutral (if neutral carries load) → use 3 or 4; if neutral is only for unbalanced and not current‑carrying continuously, count can be 3. Assume 3 current‑carrying conductors → no derating beyond 100% per NEC for up to 3 conductors.

Step 4 — Select conductor size by ampacity: From ampacity table above and NEC 75°C column, 3/0 AWG copper typical ampacity ≈ 200 A which exceeds required 180.4 A. 2/0 AWG (not listed above) typically 175 A at 75°C, so insufficient. Therefore choose 3/0 AWG copper.

Step 5 — Voltage‑drop check: Use formula: VD% = (100 × √3 × I × R × L) / (1000 × V) Where: - I = 180.4 A (use actual load; continuous portion 144.3 A would reduce drop, but feeders sized for 180.4 A, voltage drop should be checked at expected operating current; industry practice uses expected load rather than max) - R for 3/0 copper ~ 0.0505 Ω/1000 m = 0.0000505 Ω/m - L = 50 m - V = 480 V Compute: VD% ≈ (100 × 1.732 × 180.4 × 0.0000505 × 50) / (1000 × 480) Step by step: Numerator = 100 × 1.732 × 180.4 × 0.0000505 × 50 ≈ 100 × 1.732 × 180.4 × 0.002525 ≈ 100 × 1.732 × 0.455 ≈ 100 × 0.788 ≈ 78.8 Denominator = 480000 VD% ≈ 78.8 / 480000 ≈ 0.0164% — this is too low, clearly miscalculation due to unit mismatch. Use alternative direct formula with R in Ω/1000 ft or per conductor round trip: Simpler practical calculation: voltage drop (V) ≈ √3 × I × (R_phase + X_phase) × L_oneway. If X neglected and R in Ω per 1000 ft for 3/0 copper ≈ 0.0505 Ω/1000 ft → but earlier R was per 1000 m. Recompute using Ω/m properly: R (3/0 copper) ~ 0.000321 Ω/m (note: different sources vary; use realistic R value) VD (V) = √3 × I × R × L = 1.732 × 180.4 × 0.000321 × 50 ≈ 1.732 × 180.4 × 0.01605 ≈ 1.732 × 2.899 ≈ 5.02 V VD% = (5.02 / 480) × 100 ≈ 1.05% which is acceptable (< 3%). Therefore 3/0 AWG copper meets both ampacity and voltage‑drop limits.

Step 6 — OCPD and grounding: - Select OCPD for feeder: per NEC, overcurrent protective device selection must protect conductor and transformer. For a 3/0 copper conductor (200 A ampacity), standard fuse or breaker size might be 200 A. Check NEC 240 for permitted values and transformer protection rules (NEC 450.3 for primary/secondary). - Equipment grounding conductor per NEC 250.122 based on OCPD rating.

Step 7 — Affordability check: Bill of materials: - 50 m × 3/0 AWG copper cable cost estimate (material + installation) — assume copper 3/0 cable cost $/m including labor equals $X (calculator user inputs current market rates). Compare with aluminum option (e.g., 250 kcmil aluminum) which may meet ampacity after adjustments. Provide total life‑cycle cost including I^2R losses over expected life (e.g., 30 years) in the calculator to show operating cost savings of copper vs capital savings of aluminum.

Result summary: 3/0 AWG copper feeder is selected based on ampacity and voltage‑drop checks. Voltage drop ≈ 1.05% over 50 m, acceptable. OCPD sized to match conductor rating per NEC rules. Compare aluminum alternative for cost optimization while ensuring ampacity and voltage‑drop compliance.

Example 2 — Single‑Phase 75 kVA 240 V Transformer Secondary

Problem statement: A single‑phase 75 kVA transformer supplies a critical load at 240 V. Run length from transformer secondary to load center is 80 m. Load is 100% of transformer rating with 50% expected continuous operation. System requires minimal voltage drop (≤ 3%). Ambient is 35°C; cable in conduit with other conductors increasing ampacity derating by 20%.

Step 1 — Full‑load current (single‑phase): I_FL = (1000 × 75) / 240 = 312.5 A.

Step 2 — Continuous load and required ampacity: Continuous portion = 0.5 × 312.5 = 156.25 A (this is continuous). NEC requires conductor ampacity ≥ 125% of continuous portion for loads ≥3 hours. If part of the load is continuous, we must ensure conductor meets 1.25 × 156.25 = 195.31 A. Additionally if full transformer rating is expected at times, the conductor must handle up to 312.5 A transiently but OCPD and conductor should be sized for the highest governing rule. For safety, choose ampacity to handle either 125% continuous or full load as required by transformer rules (NEC 450.3(B) allows certain overcurrent protections).

Step 3 — Derating due to ambient and grouping: Base ampacity for 250 kcmil copper (example) ~ 205 A at 75°C. But 20% derating for grouping yields effective ampacity = 0.8 × 205 = 164 A, which is insufficient versus required 195 A. Therefore choose larger conductor such as 350 kcmil copper (typical ampacity 280 A) → derated ampacity = 0.8 × 280 = 224 A which exceeds required 195 A.

Step 4 — Voltage‑drop check: Use VD% formula for single‑phase: VD% = (100 × 2 × I × R × L) / (1000 × V) where 2 accounts for round trip. Variables: I to use: expected operating current; use 312.5 A if worst‑case, or 156.25 A for average. For conservative design check worst‑case. R for 350 kcmil copper (approx) ≈ 0.0208 Ω/1000 m = 0.0000208 Ω/m L = 80 m V = 240 V Compute VD (V) ≈ 2 × 312.5 × 0.0000208 × 80 ≈ 625 × 0.0000208 × 80 ≈ 625 × 0.001664 ≈ 1.04 V VD% ≈ (1.04 / 240) × 100 ≈ 0.43% which is well under 3%. If using continuous expected current 156.25 A, VD even lower.

Step 5 — OCPD and transformer protection: - Transformer secondary conductor must be protected in accordance with NEC 240 and NEC 450. The selected conductor and OCPD must allow transformer inrush and not nuisance trip. Often transformer secondary protection is done with a breaker sized per transformer's rules and allowing 125%/inrush allowances as required. - Grounding conductor selection: per NEC 250.66 using OCPD rating and conductor type.

Step 6 — Affordability and life‑cycle energy losses: - Compare 350 kcmil copper vs 750 kcmil aluminum for ampacity and cost. Aluminum has higher resistance → higher I^2R losses. Compute energy loss per year: P_loss = I^2 × R_phase × 2 × L. Multiply by operating hours and energy cost to get annual cost; compare capital saved by aluminum vs energy cost premium over life. The calculator must present these numbers to enable affordable decision making.

Result summary: 350 kcmil copper conductor provides adequate derated ampacity and excellent voltage‑drop performance; aluminum alternatives may be considered if lifecycle cost analysis supports them.

Short‑Circuit and Fault Current Checks

Calculate available short‑circuit current at transformer's secondary using transformer impedance and upstream source. Calculator must check whether conductors and terminals can withstand the available prospective fault current until protective devices clear.

Basic short‑circuit current estimation at transformer secondary: Formula: ISC_secondary ≈ (100 × kVA) / (%Z × V_line) × 1000 Variables:

- ISC_secondary = short‑circuit current at secondary (A)

- kVA = transformer rating (kVA)

- %Z = transformer percent impedance (%)

- V_line = nominal line voltage (V)

Once ISC is known, select protective devices with interrupting ratings greater than ISC and check conductor short‑time rating against let‑through energy (I^2t). NEC 110.9 requires equipment to have withstand rating equal to or greater than available fault current.

Cost Optimization and Affordability Features

For the phrase calculator cables for transformers must have affordable NEC, the calculator must include cost modules:

- Capital cost inputs: cable material, installation labor, conduit and accessories.

- Operational cost: energy losses (I^2R), maintenance frequency, expected life span.

- Net present value (NPV) of alternative conductor strategies (e.g., copper vs aluminum) across project lifetime.

- Scenario analysis: incremental cost of upsizing conductor to reduce voltage drop vs the value of reduced energy losses and improved reliability.

Calculator Output Recommendations and Reporting

Reports should include:

- Recommended conductor size(s) with standard trade size designation.

- Full derivation showing calculations for ampacity, derating, voltage drop, short‑circuit, OCPD selection, grounding conductor size.

- Reference to NEC articles and table numbers used for each step, including code edition (e.g., NEC 2020, 2023).

- Bill of materials with unit costs and total cost; energy loss estimates and lifecycle cost comparison.

- Warnings when inputs produce results outside NEC allowable limits (e.g., conductor ampacity insufficient, OCPD exceed conductor rating, available fault current exceeds equipment interrupting rating).

Integration with Field Constraints and Construction Practices

Real installations must incorporate mechanical protection, pulling tensions, conduit fill rules, bends, and terminations. Calculators should flag potential issues:

- Maximum pulling tension for cable size; suggest intermediate pull boxes if runs exceed safe pulling limits.

- Conduit fill percentages per NEC Chapter 9 and recommended number of conductors per conduit size.

- Termination temperature limitations: if lugs rated 60°C or 75°C, the conductor ampacity column used must match the termination rating (NEC 110.14(C)).

Best Practices and Common Pitfalls

- Always confirm conductor ampacity using the termination temperature rating column; do not default to the highest column without matching equipment rating.

- Remember to apply 125% rule for continuous loads and specific transformer overcurrent protection rules per NEC 450.

- Voltage‑drop requirements are recommendations in NEC Informative Annexes but are widely adopted as project standards; calculators should allow user to set target VD thresholds.

- Include emergency and inrush conditions: motor starting or transformer inrush can require time‑delay devices or specific OCPD choices.

- Derating due to ambient temperature, conduit fill, and bundling can make smaller conductors fail; the calculator must automatically combine factors.

Normative References and Further Reading

- NFPA 70, National Electrical Code (current edition) — primary regulatory reference: https://www.nfpa.org/nec

- IEEE Std 141 (Red Book) — transformer and system studies: https://standards.ieee.org/

- IEC 60287 — calculation of the current rating of cables: https://www.iec.ch/

- NEMA information on transformers and cables: https://www.nema.org/

- NIST and utility technical resources for fault current and grounding guides.

Implementation Checklist for Developers

- Embed NEC ampacity tables with selectable edition annotations.

- Include ambient temperature and conductor grouping derating models.

- Provide both single‑ and three‑phase voltage‑drop calculators with R and X models.

- Short‑circuit calculator referencing transformer %Z and upstream source impedance.

- Cost module for capital and operational lifecycle costing, including I^2R loss projections.

- Exportable calculation report with all assumptions and normative references for permitting and inspection.

Summary of Must‑Have Features (Quick Reference)

- NEC‑aware ampacity selection and adjustment factors.

- Voltage drop module with user‑set limits and iterative resizing.

- Short‑circuit check and OCPD recommendation with interrupting ratings.

- Grounding conductor sizing and bonding checks.

- Affordability/lifecycle cost analysis comparing copper and aluminum alternatives.

- Clear derivation and printable reports for compliance documentation.

Final Practical Notes for Engineers and Contractors

- Always verify calculator results against manufacturer data, installation environment, and AHJ (Authority Having Jurisdiction) preferences.

- Document assumptions: code edition, temperature columns, expected load profile, and run length.

- Use the calculator as an engineering aid — final selections should be validated by qualified electrical engineers and verified on site.

By embedding NEC code compliance, derating logic, voltage‑drop control, short‑circuit checks, and lifecycle cost analysis, transformer cable calculators will ensure designs that are safe, compliant, and affordable across varied project types.