This article explains an interactive electrical demand factor calculator for precise load sizing and selection.

Engineers can apply selectable rules, national standards, and custom diversity to optimize calculated demand factors.

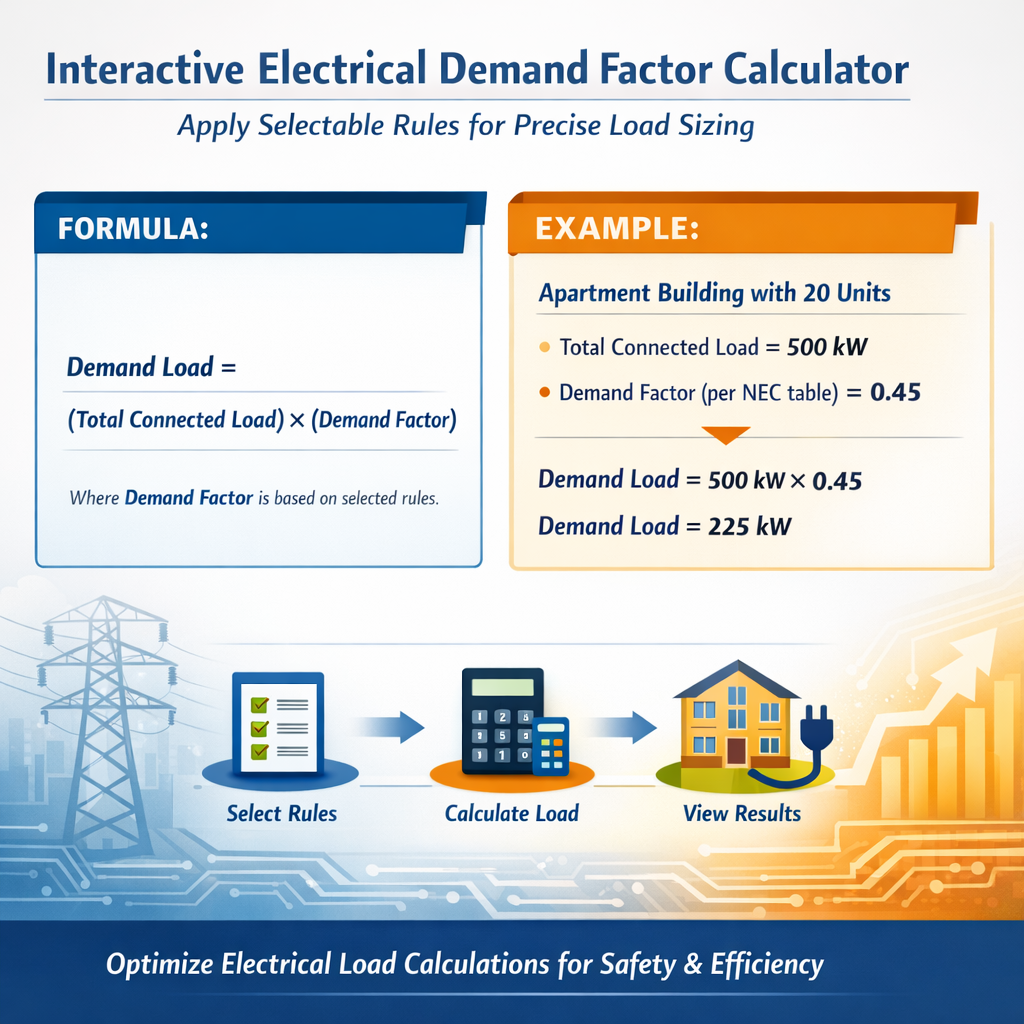

Interactive Electrical Demand Factor Calculator for Precise Load and Current Sizing

Purpose and scope of an interactive demand factor calculator

An interactive electrical demand factor calculator applies selectable rules to convert connected load into design maximum demand. It supports designers, electrical engineers, and energy managers for accurate sizing of transformers, switchgear, and conductors. The calculator allows rule sets to be chosen (for example NEC, IEC, local code, or owner-defined), enabling deterministic and probabilistic scenarios.

Key objectives and outputs

- Convert connected loads into maximum demand using selectable demand and diversity rules.

- Produce kVA, A (current), and thermal ratings for equipment and conductor sizing.

- Allow sensitivity analysis and scenario comparison (worst-case, typical, and energy-optimized).

- Provide traceable documentation and normative references for regulatory compliance.

Fundamental definitions and relations

Accurate use of the calculator depends on consistent definitions for connected load, demand, demand factor, and diversity factor.

Essential definitions

- Connected load: the sum of nameplate ratings for all equipment connected to the electrical system.

- Maximum demand (Pmax): the highest power consumption measured or expected for the system over a specified interval.

- Demand factor (DF): ratio of maximum demand to connected load. DF ≤ 1.0 typically.

- Diversity factor (γ): ratio of the sum of individual maximum demands to the maximum system demand; γ ≥ 1.0.

Core formulas (HTML-only)

Variable explanations and typical values

- P_max — maximum demand in watts (typical range: lighting 0.5–1.0 W/ft², motors per nameplate).

- ΣP_connected — total connected load in watts (sum of nameplate ratings).

- DF — dimensionless demand factor, typical values depend on load type (see tables below).

- PF — power factor (typical: lighting and receptacle loads 0.9–1.0, motors 0.8–0.95, mixed systems 0.85–0.95).

- V_line — line-to-line voltage in volts (e.g., 208, 400, 480 V); single-phase uses line-to-neutral.

- S_required — required apparent power in kVA to size transformers or service equipment.

Selectable rules and algorithmic workflow

The calculator must implement multiple selectable rule categories to be flexible and compliant with various codes and owner preferences.

Rule categories

- Code-based rules (e.g., NEC Article 220 series, IEC 60364 guidance): deterministic tables and demand factors.

- Equipment-class rules: specific demand factors per equipment category (lighting, HVAC, motors, cooking, elevators, etc.).

- Occupancy and usage rules: rules for office, residential, industrial, healthcare, and retail applications.

- Temporal and duty-cycle rules: incorporate on-off duty cycles, coincidence probability, and load profiles.

- Custom rules: user-defined factors for specialized installations or measured load diversity.

Algorithmic steps implemented in the interactive tool

- Input stage: enter connected loads with classification, quantity, and nameplate ratings.

- Assign rule: select applicable rule set for each load class (code table or custom factor).

- Apply modifiers: apply utilization factors, demand reductions, and duty-cycle multipliers.

- Aggregate per distribution section: compute DF and P_max for feeders, panels, transformers.

- Calculate electrical sizing: compute kVA and current, then select nearest standard equipment rating with required margin.

- Output reports: provide calculation trace, normative citations, and sensitivity results.

Typical demand factor tables

Below are representative demand factors commonly used as a starting point. These are for engineering estimation — always reference applicable code tables when required.

| Load Type | Connected Load Definition | Typical Demand Factor (DF) | Notes |

|---|---|---|---|

| General lighting — commercial | Interior lighting circuits | 0.60–0.90 | Higher densities in retail; use code where specified |

| General lighting — residential | Dwelling unit lighting | 0.80–1.00 | Small circuits often sized conservatively |

| Small-appliance circuits (residential) | Kitchen and laundry receptacles | 0.35–0.75 | NEC provides tabulated values for dwelling units |

| HVAC (unitary) | Space-conditioning equipment | 0.65–1.00 | Coincidence with lighting varies; apply demand rules |

| Motors (individual) | Induction or synchronous motors | 1.00 (connected) / diversity depends on grouping | Starting currents require separate evaluation |

| Motor group diversity | Multiple motors on same feeder | 0.40–0.85 | Use IEC/NEC group demand rules |

| Electric heating | Resistive heaters, unit heaters | 0.90–1.00 | Often no diversity allowed for continuous loads |

| Elevators | Traction or hydraulic elevator system | 0.25–0.70 | Use manufacturer duty cycle data |

| Appliance/Equipment | Typical Connected Power | Typical Utilization Factor | Reference |

|---|---|---|---|

| Office workstation | 0.10–0.25 kW each | 0.5–0.8 | CIBSE, IEEE |

| Retail display lighting | 0.5–2.0 W/ft² | 0.6–0.9 | Manufacturer and standards |

| Packaged rooftop unit (RTU) | 3–30 kW | 0.7–1.0 | AHRI, HVAC datasheets |

| Industrial motor (10–50 Hp) | 7.5–37 kW | 1.0 connected, group DF applies | IEEE/NEMA motor guides |

Applying national and international standards

Selectable rules must include authoritative normative references and implement tables or calculation methods exactly where codes mandate.

Common normative references

- NFPA 70, National Electrical Code (NEC) — Article 220: demand loads and service calculations. Official site: https://www.nfpa.org/

- IEC 60364 — Electrical installations for buildings; provides international practices. IEC link: https://www.iec.ch/

- BS 7671 (IET Wiring Regulations) — UK wiring rules with guidance on diversity. IET: https://www.theiet.org/

- IEEE standards for power systems and transformer sizing: https://standards.ieee.org/

- ASHRAE and CIBSE for HVAC diversity and building profiles: https://www.ashrae.org/ and https://www.cibse.org/

Implementing code tables

When a selected rule is a code table (e.g., NEC 220.82, 220.55), the calculator must retrieve the exact tabulated factors, apply any multipliers (such as demand allowances per occupancy), and include code citations in the output report. For dwellings, follow the NEC prescribed method for small-appliance and laundry circuits and the lighting loads per area.

Transformer and service sizing methodology

Transformer sizing converts the computed maximum demand into kVA and then into current for conductor and protective device selection.

Step-by-step sizing workflow

- Compute ΣP_connected for the load group.

- Apply demand factors to obtain P_max for that group: P_max = ΣP_connected × DF.

- Sum P_max values for distribution sections according to their point of common connection.

- Compute S_required(kVA) = (ΣP_max) / (PF × 1000).

- Select next higher standard kVA transformer rating accounting for overload and inrush (typically 125% for motors if required by code).

- Calculate conductor ampacity from I = (S_required × 1000) / (√3 × V_line) and select conductor and protective device per local code derating rules.

Example formula with typical values shown

Handling motor loads and starting currents

Motors present unique sizing challenges: they have locked-rotor currents (LRC), service factors, and group diversity rules. The calculator must separate continuous running power from transient starting requirements.

Motor sizing rules and mitigation

- Size conductors and protection for continuous motor full-load current per nameplate and service factor.

- Evaluate starting currents and apply diversity or reduced voltage starting methods to mitigate supply voltage dip.

- Use motor starting diversity rules per the selected code or apply manufacturer starting duty curves for multiple motors starting simultaneously.

Real-world example 1 — Commercial office building

Scenario: A three-floor office building with typical loads — lighting, receptacles, small HVAC, and a few small motors. Compute demand at main service and specify transformer rating.

Given data

- Floor area: 3 floors × 2,500 ft² = 7,500 ft².

- Lighting connected load: 1.2 W/ft² typical; ΣP_light = 7,500 × 1.2 = 9,000 W.

- Receptacle loads (general-purpose): estimate 1.5 W/ft²; ΣP_recp = 7,500 × 1.5 = 11,250 W.

- Server room equipment (dedicated room): ΣP_server = 12,000 W.

- RTUs: two units, rated 15 kW each (connected), ΣP_RTU = 30,000 W.

- Small motors (pumps/fans): total nameplate ΣP_motors = 8,000 W.

- Assumed power factor PF = 0.9 for mixed load.

Selectable rule set

- Lighting DF = 0.65 (commercial office typical).

- Receptacles DF = 0.5 (diverse use patterns).

- Server room DF = 1.00 (continuous, no diversity).

- RTU DF = 0.85 (HVAC coincidence considered).

- Motors: apply motor group diversity DF_motors = 0.7.

Calculations

Step 1 — Apply DF to each load class:

Step 2 — Sum Pmax at service:

ΣPmax = 5850 + 5625 + 12000 + 25500 + 5600 = 546,? Wait compute: 5850+5625=11475; +12000=23475; +25500=48975; +5600=54575 W. So ΣPmax = 54,575 W.

Step 4 — Select nearest standard transformer rating. Common standard sizes: 45 kVA, 75 kVA. Select 75 kVA to provide margin and accommodate future load growth and inrush. Check inrush and motor starting: with motor starting strategies, 75 kVA can be validated by voltage dip calculation.

Step 5 — Compute supply current for 400 V three-phase:

Detailed commentary and checks

- Transformer selected (75 kVA) provides ~24% headroom above computed 60.64 kVA — suitable for foreseeable diversity and future additions.

- Verify protective device ratings: a 125 A breaker (standard) may be used; confirm conductor ampacity and derating per installation rules.

- Server room continuous load should be assessed for standby/UPS requirements and may require separate calculation per NFPA 70 and NFPA 110.

Real-world example 2 — Light industrial facility with motor groups

Scenario: A workshop with multiple motor loads, welding machines, lighting, and process heating. Provide transformer and feeder sizing while considering motor starting and welding duty.

Given data

- Welding equipment: three welding stations, each 25 kW connected (peak duty but non-simultaneous); ΣP_weld = 75,000 W.

- Motors: five motors, rated 30 kW each; ΣP_motors = 150,000 W.

- Lighting and general loads: ΣP_light_recp = 25,000 W.

- Process resistive heaters: ΣP_heating = 40,000 W (continuous).

- Plant operating PF for motors and welders assumed PF = 0.85; resistive loads PF = 1.0; overall conservative PF = 0.9.

Selectable rule set

- Welding stations: apply coincidence factor 0.35 (welders rarely all active simultaneously) or use manufacturer duty cycle.

- Motors: apply group diversity per IEC/NEC — use DF_motors = 0.6 for five motors with staggered operation.

- Heating: DF_heating = 1.0 (continuous, no diversity).

- Lighting: DF_light = 0.7.

Calculations

Aggregate maximum demand:

Select transformer: standard sizes around 150, 225, 250 kVA. Select 225 kVA initial candidate; recompute headroom: 225 kVA > 193.06 kVA (≈16% margin). If motor starting inrush or welding harmonic distortion is a concern, select 250 kVA or apply soft-start measures.

Calculate three-phase current at 480 V:

Motor starting verification

For each 30 kW motor, locked-rotor current (LRC) might be ~6 × FLC (full-load current). Estimate motor full-load current:

LRC ≈ 6 × 42.7 ≈ 256 A per motor. Simultaneous starting of multiple motors could cause unacceptable voltage dip. Mitigation options:

- Use soft-starters or VFDs to limit starting current.

- Stagger motor start times using control systems.

- Increase transformer size to withstand inrush current and maintain acceptable voltage regulation.

- Use an inrush study (short-circuit impedance and motor start model) to verify compliance with voltage dip limits.

Uncertainty, probabilistic methods, and sensitivity analysis

Deterministic demand factors are often conservative. For large portfolios or critical facilities, probabilistic methods improve accuracy by modeling individual load on/off distributions.

Monte Carlo and statistical approaches

- Assign probability distributions for each load (e.g., Bernoulli for on/off, Beta for utilization percent).

- Run Monte Carlo simulations to estimate confidence intervals for maximum demand.

- Use results to select design kVA for specified reliability (for example, choose kVA that yields less than 1% chance of overload).

Sensitivity analysis outputs

- Identify the most influential loads via tornado charts or variance decomposition.

- Provide recommendations for demand-side management (DSM) to reduce peak demand.

- Quantify cost-benefit of transformer up-sizing versus motor soft-start equipment.

Harmonics, non-linear loads, and power quality considerations

Modern equipment like VFDs, UPS, and welding machines generate harmonics that impact transformer and conductor heating and kVA sizing. The calculator should include harmonic derating factors and K-factor transformer selection where necessary.

Harmonic evaluation steps

- Classify non-linear loads and determine harmonic current spectrum from datasheets or measured data.

- Compute distortion factor and K-factor per IEEE/IEC standards.

- Apply K-factor to select transformer rated for harmonic heating or consider oversized standard transformer.

- Assess neutral conductor sizing for triplen harmonics in systems with single-phase nonlinear loads.

Reporting, traceability, and auditability

Outputs from the interactive calculator must be auditable and include clear traceability of rule selection, table references, and calculation steps.

Recommended report contents

- Summary table of connected loads and Pmax per category.

- Selected rules and normative references with direct citations.

- Complete formulae and numeric substitutions for each calculation step.

- Equipment selection rationale and margins applied.

- Sensitivity and probabilistic analysis summary when used.

- Assumptions and limitations for the selected rule set.

Integration with BIM and measurement systems

For modern design workflows, integrate the calculator with BIM models and building energy management systems (BEMS) to extract connected loads and to validate calculated demand with measured metered data.

Data exchange considerations

- Support import/export of load schedules in common formats (CSV, IFC attributes for BIM).

- Allow time-series import from metering systems for validation and probabilistic modeling.

- Provide API for programmatic rule invocation and embedding into design automation workflows.

Best practices and practical tips

- Always document the chosen rule set and code edition used (e.g., NEC 2023, IEC 60364-5-52).

- Default to conservative values for critical continuous processes unless measured data justifies reduction.

- Perform motor starting studies when multiple large motors share a transformer or supply bus.

- Consider future expansions and include spare capacity or modular upgrades.

- Validate model outcomes with short-term metering after commissioning and adjust rules accordingly.

References and authoritative resources

- NFPA 70, National Electrical Code (NEC). Available through NFPA: https://www.nfpa.org/

- IEC 60364 series — Electrical installations of buildings. IEC: https://www.iec.ch/

- BS 7671 Requirements for Electrical Installations (IET Wiring Regulations). IET: https://www.theiet.org/

- IEEE Standard 141 (Red Book) — power system design and practices. IEEE: https://standards.ieee.org/

- AHRI and CIBSE guidance for HVAC loads and diversity: https://www.ashrae.org/, https://www.cibse.org/

- Manufacturer datasheets and ANSI/NEMA motor standards for starting currents and duty cycles.

Final operational checklist for using the interactive calculator

- Verify connected load data and nameplate ratings; correct unit errors.

- Select the appropriate code edition and local amendments in the rule set.

- Choose demand/diversity factors per load class or use measured profiles.

- Run deterministic calculation and then a probabilistic sensitivity study if required.

- Document all assumptions, normative citations, and chosen equipment ratings.

- Plan commissioning metering to validate and refine demand factors post-occupancy.