This article explains fast emergency lighting branch circuit load calculations for life safety panels accurately.

Engineers will learn formulas, typical values, examples, norms, and instant calculator workflow to implement efficiently.Instant Emergency Lighting Branch Circuit Load Calculator — Life Safety Panel Branch Sizing

Purpose and scope for rapid life-safety branch circuit load calculation

This document defines a stepwise method to size emergency lighting branch circuit loads, inverter and battery capacities, and branch circuit conductor and overcurrent protection estimates for life safety panels. It targets electrical engineers, designers, code officials, and commissioning teams who need a reproducible, code-aware instant calculator process that returns reliable design outputs in minutes.

Key regulatory context and authoritative references

Emergency lighting and life-safety power distributions are regulated by several international and national standards. The most frequently applicable and authoritative documents include:

- NFPA — National Fire Protection Association (NFPA 70, National Electrical Code® (NEC), Articles 700 and 701).

- NFPA 101 — Life Safety Code® (egress illumination requirements).

- UL 924 — Emergency Lighting and Power Equipment (performance and duration).

- International Building Code (IBC) and ICC resources for egress and means-of-egress illumination requirements.

- IEC and regional electrical standards for inverter and battery system safety.

Designers must confirm local amendments and AHJ (Authority Having Jurisdiction) interpretations, particularly for required emergency durations, whether emergency loads are considered continuous, and permitted voltage levels.

Essential inputs for instant calculator

To produce a valid output rapidly, the calculator requires precise inputs. Provide these parameters:

- List of emergency luminaires and exit signs: quantity and rated emergency wattage per device.

- Supply voltage and system type: single-phase 120/277 V or three-phase 208Y/120 V, 480Y/277 V, etc.

- Emergency duration requirement (minutes), typically 90 minutes for egress lighting per NFPA/UL norms.

- Inverter/charger efficiency and power factor (if inverter used to supply AC emergency loads).

- Battery nominal DC voltage for bank design (common values: 48 V, 120 V, 240 V DC stacks depending on vendor).

- Any demand or diversity factors mandated by code or allowed by the AHJ.

- Whether the loads are considered continuous per NEC (continuous = 3 hours or longer).

Common fixture wattage and sign tables

| Device Type | Typical LED Rated Power (W) | Emergency Module / Battery Pack Typical Additional (W) | Typical Emergency Wattage (W) |

|---|---|---|---|

| LED Downlight (residential/office) | 8–12 | 6–10 | 10–18 |

| LED Troffer 2x2 / 2x4 | 28–50 | 10–20 | 30–70 |

| LED High-bay (warehouse) | 80–240 | 20–60 | 100–300 |

| Exit sign (LED) | 2–6 | — | 2–6 |

| Remote emergency head (pair) | — | 6–20 | 6–20 |

| Emergency inverter branch average per fixture | — | — | 10–50 |

| Common System Voltage | Single-Phase Current (A) per 1000 W | Three-Phase Current (A) per 1000 W, PF=1 |

|---|---|---|

| 120 V (single-phase) | 8.33 | — |

| 277 V (single-phase lighting) | 3.61 | — |

| 208Y/120 V (three-phase) | — | 2.78 |

| 480Y/277 V (three-phase) | — | 2.02 |

Core formulas and variable explanations

All formulas below are shown in plain HTML text. Each variable is explained and typical values are included.

1) Single-phase current calculation

Where:

- I = current in amperes (A)

- P = total emergency power in watts (W) — sum of emergency wattages of all devices

- V = line-to-neutral or line voltage in volts (V) — e.g., 120 V or 277 V

Typical values example: P = 3000 W, V = 277 V -> I = 3000 / 277 = 10.83 A.

2) Three-phase current calculation (balanced)

Where:

- I = line current in amperes (A)

- P = total three-phase emergency power in watts (W)

- √3 = 1.732 (constant)

- V_LL = line-to-line voltage in volts (V) — e.g., 480 V or 208 V

- PF = power factor (unitless), typical 0.9–1.0 for LED loads/inverters

Typical values example (PF=1): P = 12,000 W, V_LL = 480 V -> I = 12000 / (1.732 × 480 × 1) = 14.44 A.

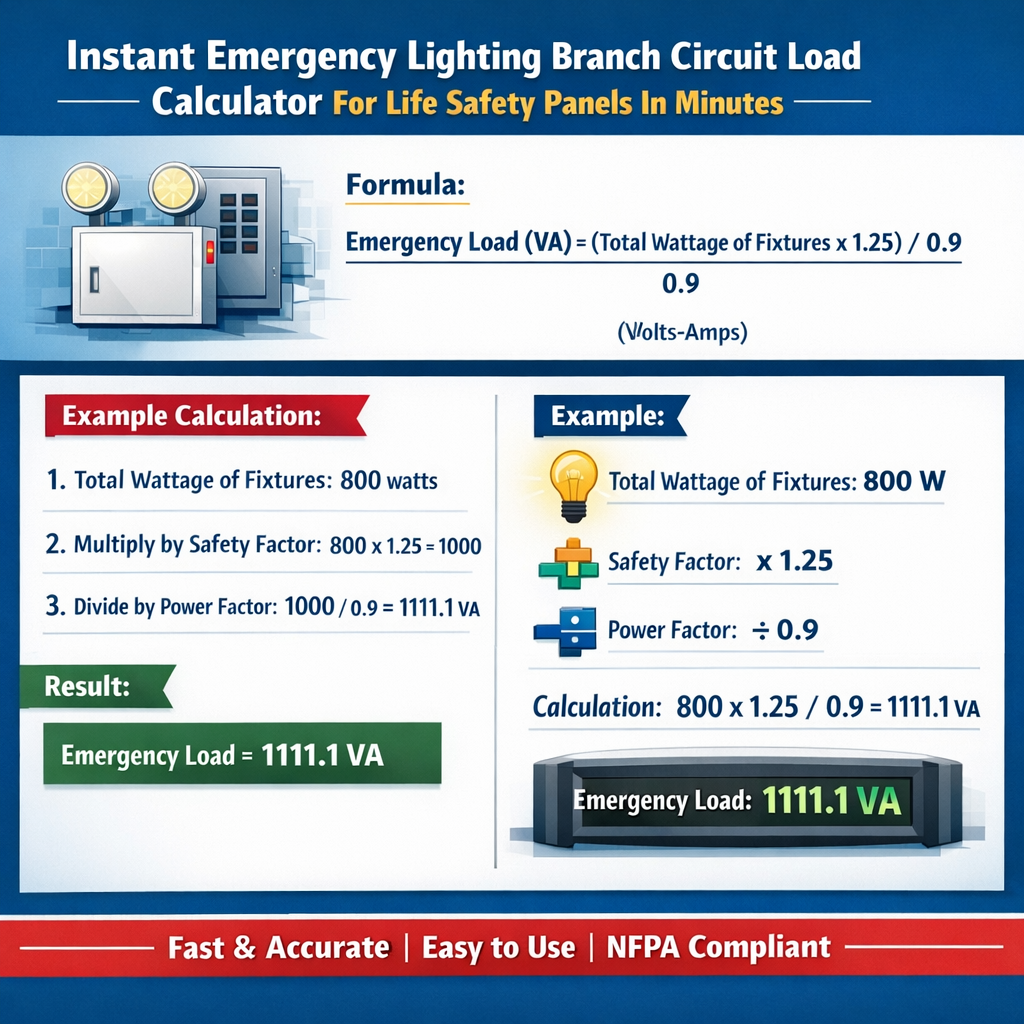

3) Converter/Inverter apparent power and VA sizing

Where:

- S_VA = apparent power in volt-amperes needed from inverter

- P_out = AC output real power required (W)

- PF = inverter output power factor (typical 0.9–1.0)

- η = inverter efficiency (typical 0.85–0.98)

Typical values example: P_out = 5000 W, PF = 0.9, η = 0.92 -> S_VA = 5000 / 0.9 / 0.92 ≈ 6039 VA.

4) Battery ampere-hour (Ah) sizing for duration

Where:

- Ah = battery ampere-hours required

- P_total = total emergency DC-equivalent load (W). If inverter supplies AC loads, use P_out = AC load (W).

- t_hours = emergency duration in hours (e.g., 1.5 for 90 minutes)

- V_batt = nominal battery bank voltage (V), typical 48 V, 120 V, 240 V

- η_inv = inverter efficiency (0 < η ≤ 1)

- DOD = maximum usable Depth of Discharge (decimal), typical 0.8 for lead-acid (80%) or 0.9 for Li-ion depending on vendor)

Typical values example: P_total = 3000 W, t_hours = 1.5, V_batt = 120 V, η_inv = 0.92, DOD = 0.8

5) Battery capacity with reserve margin

Where Safety_factor is typically 1.10 to 1.25 (10–25%) depending on environmental and aging allowances.

Algorithm for an instant calculator (procedural)

- Collect device list: quantities and emergency wattages.

- Sum emergency wattages to get P_total (W).

- Select supply voltage and system type.

- Calculate branch circuit current using single- or three-phase formula.

- Apply PF and inverter efficiency to get inverter VA sizing.

- Decide battery nominal voltage and DOD; compute Ah using the battery formula.

- Apply safety factors and verify breaker and conductor sizing per NEC and local code.

- Produce summary: total W, branch current, inverter VA, battery Ah, recommended breaker size, conductor preliminary size.

Conductor and overcurrent sizing considerations

Follow NEC and local amendments. Key points:

- NEC defines continuous load as 3 hours or more. If emergency duration <3 hours (commonly 90 minutes), loads are not automatically "continuous" per NEC 100 definition; therefore the 125% continuous multiplier may not apply. Verify AHJ interpretations.

- Where loads are considered continuous or standby continuous, multiply by 125% for conductor ampacity and equipment rating per NEC 210.19(A)(1) and 215.2(A)(1) as applicable.

- Consider inrush currents for LED drivers, battery charger ripple, and inverter surge rating when selecting breakers and conductor ampacity.

- For three-phase balanced loads, size conductors for calculated phase currents and apply correction factors (ambient, bundling) from NEC 310.

| Calculated Current (A) | Suggested Breaker Size (A) | Suggested Minimum Copper Conductor (AWG) | Notes |

|---|---|---|---|

| 0–15 | 15–20 | 14 AWG–12 AWG | Typical small branch circuits |

| 15–30 | 20–35 | 12 AWG–10 AWG | Standard lighting branches |

| 30–60 | 40–70 | 10 AWG–6 AWG | Large luminaire groups or inverter outputs |

| 60–100 | 70–110 | 6 AWG–3 AWG | Feeder circuits; consult NEC derating |

Two real-world example calculations

Example 1 — Small office floor emergency lighting on 277V single-phase

Project brief: A single open-plan office floor requires emergency lighting supplied from a life safety panel. Devices:

- 40 LED downlights — emergency wattage 12 W each (unit-integrated emergency pack)

- 8 LED troffers — emergency wattage 40 W each

- 12 exit signs — 4 W each

- System voltage: 277 V single-phase lighting branch

- Required duration: 90 minutes (1.5 hours)

- Inverter efficiency assumed 92% (0.92). Inverter PF = 0.95 (conservative).

- Battery nominal voltage chosen: 120 V DC bank

- Battery DOD (usable) assumed 0.8 (80%)

Step 1 — Sum emergency wattages:

Step 2 — Branch current on 277 V single-phase:

Design note: Very low current; often multiple floors or additional loads will be aggregated onto same panel. Still, minimum breaker selection should follow device manufacturer and local code. A 15 A branch breaker is typical for such lighting branch.

Step 3 — Inverter VA sizing:

Round up and select a 1200 VA nominal inverter for margin and surge handling.

Step 4 — Battery Ah sizing:

Apply a safety factor of 1.15 -> Ah_design ≈ 16.6 Ah. Choose a standard battery module of 20 Ah at 120 V system (or parallel modules to achieve capacity).

Step 5 — Verification and breaker sizing:

- Branch current 3.06 A -> minimum breaker 15 A standard lighting branch.

- Conductor: 14 AWG or 12 AWG per run length and derating — 12 AWG recommended for mechanical protection and voltage drop margins.

- Confirm AHJ for continuous load policies (if considered continuous, apply 125% multiplier to current and re-evaluate conductor/breaker). For 90-minute duration, typically not continuous per NEC.

Example 2 — Medium-sized retail mall corridor emergency system on 480Y/277V three-phase

Project brief: Corridor emergency lighting and exit signage across three zones supplied from a life-safety three-phase panel. Devices and distribution:

- Zone A: 150 LED troffers (40 W emergency each)

- Zone B: 80 LED downlights (12 W each)

- Zone C: 60 high-bay fixtures for atrium emergency (120 W each)

- Exit signs total: 30 × 4 W

- Supply: 480Y/277 V three-phase lighting system

- Required duration: 90 minutes (1.5 hours)

- Inverter efficiency = 0.90 (90%), PF = 0.95

- Battery nominal voltage = 240 V DC bank

- Battery usable DOD = 0.9 (Li-ion vendor spec)

Step 1 — Sum emergency wattages:

Step 2 — Three-phase line current calculation (balanced assumed):

Design note: Balanced three-phase current ~18.1 A per phase — choose appropriate feeder and breaker sizes. Because loads are substantial, consider distribution across multiple branch breakers for redundancy.

Step 3 — Inverter VA sizing:

S_VA = P_out / PF / η = 14280 / 0.95 / 0.90 = 14280 / 0.855 ≈ 16,695 VA

Select a 20 kVA inverter or parallel inverters to meet surge and redundancy requirements.

Step 4 — Battery Ah sizing:

Apply safety factor 1.20 for age and temperature -> Ah_design ≈ 132.2 Ah. Vendor battery modules of 150 Ah at 240 V preferable.

Step 5 — Conductor and overcurrent considerations:

- Calculated phase current 18.1 A. If loads are not continuous, standard breaker could be 25 or 30 A per phase; but group distribution into multiple feeders to reduce single point failures.

- Confirm voltage drop limits for long runs; if >3% drop, increase conductor size.

- If AHJ treats emergency loads as continuous, multiply P_total by 1.25 -> recalc currents and conductor sizes accordingly.

Practical checks, commissioning and verification

After calculation and equipment selection, perform the following steps:

- Confirm fixture emergency wattages with manufacturer labels and emergency module power draws.

- Validate inverter surge capability for starting LED drivers or emergency ballast inrush.

- Perform battery capacity testing at design discharge rate to verify Ah performance at site temperature.

- Commission the system with timed load tests: full-load 90-minute discharge verification under AHJ observation if required.

- Label circuits and provide schematics in panelboard schedules indicating emergency branch circuits and durations.

Common pitfalls and mitigation strategies

- Using nameplate rated normal running wattage instead of emergency mode wattage — always use actual emergency-rated wattage published by the manufacturer.

- Neglecting inverter PF and efficiency — undervaluing inverter VA results in overloaded inverters.

- Assuming continuous load rules always apply — check AHJ; misapplication can oversize equipment unnecessarily.

- Omitting aging, temperature, and DOD allowances when sizing batteries — leads to end-of-life failure before required duration.

- Failing to consider voltage drop on long branch circuits — may reduce illumination below code requirements during emergency operation.

Checklist for instant calculator outputs

- Total emergency connected load (W)

- Calculated branch current(s) (A) for selected voltage and phase

- Recommended inverter VA and surge capability

- Battery bank nominal voltage and Ah required

- Suggested battery reserve/safety factor

- Preliminary breaker and conductor sizes (with notes on continuous load application)

- Commissioning tests required and expected results

Normative references and further reading

- NEC (NFPA 70) — Article 700 Emergency Systems: https://www.nfpa.org/

- NEC (NFPA 70) — Article 701 Legally Required Standby Systems: https://www.nfpa.org/

- NFPA 101 — Life Safety Code: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=101

- UL 924 — Emergency Lighting and Power Equipment: https://www.ul.com/

- International Building Code (IBC) — Means of Egress and Emergency Illumination: https://codes.iccsafe.org/

- IEC standards for batteries and inverters — https://www.iec.ch/

Final technical recommendations

Implementing an instant branch-circuit load calculator for life-safety panels requires rigorous input verification, conservative device and inverter selection, and battery sizing that includes environmental and aging margins. By standardizing inputs (device list, system voltage, inverter specs, battery bank voltage), using the formulas supplied, and following the procedural algorithm, engineers can produce reliable design outputs within minutes that conform to NFPA, NEC, and UL expectations while remaining flexible for AHJ-specific requirements.