This article provides a technical method to prevent conduit jams during conductor installation and testing.

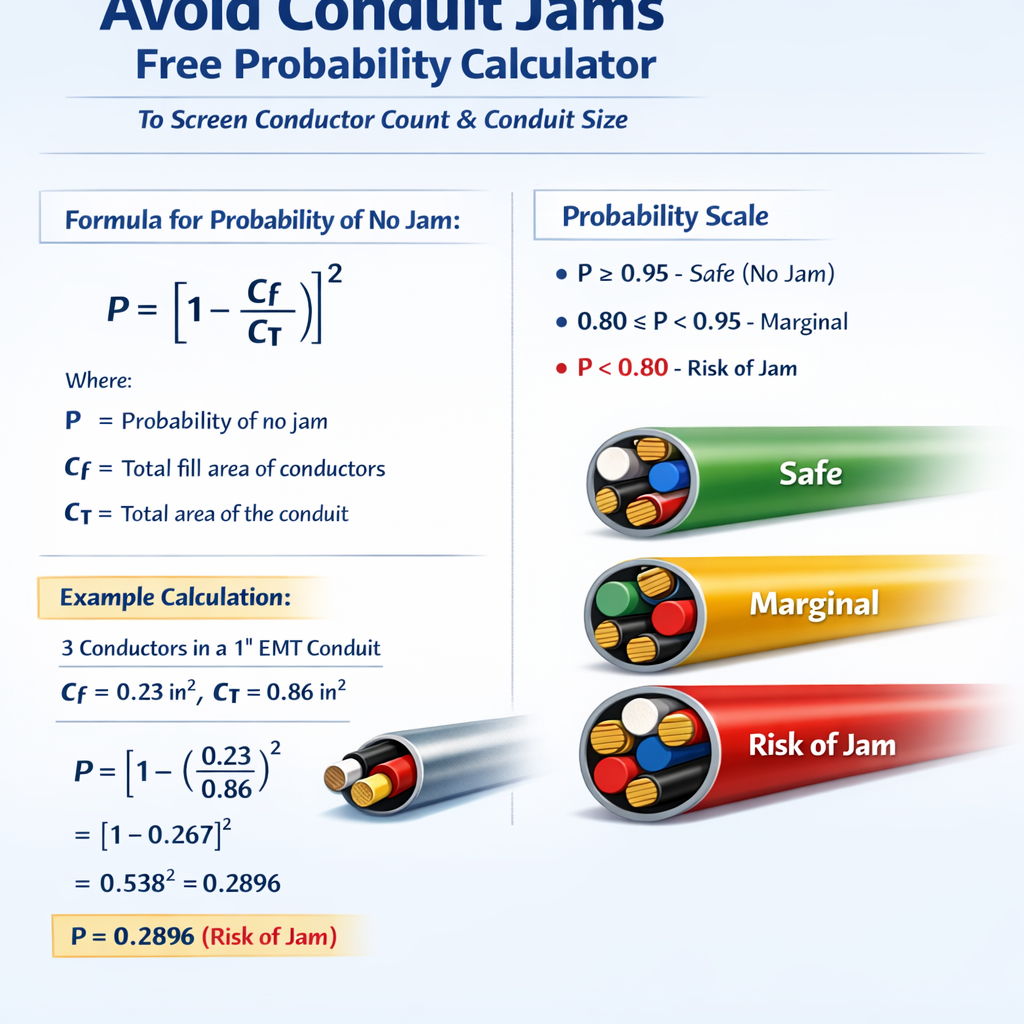

A free probability calculator screens conductor counts against conduit size to reduce blockage risk effectively.

Jam-Free Pull Probability Calculator for Conductor Count vs Conduit Size Screening

Scope and applicability

This document describes a quantitative screening workflow and a probability model to evaluate the risk of conduit jams (mechanical blockage) when pulling insulated conductors through circular conduits. The methods combine:- Geometry-based area calculations for conductors and conduits,

- Regulatory screening by recognized conduit-fill percentages,

- A probabilistic jam estimator based on packing fraction and empirical jamming thresholds,

- Design guidance and recommended mitigations if the risk exceeds targets.

Fundamental geometric calculations

Accurate screening begins with area calculations for the conduit internal cross-section and the apparent cross-sectional area of each insulated conductor. Use these base formulas.Conduit internal cross-sectional area

Where:

- A_conduit = internal cross-sectional area of conduit (in square inches)

- D_id = internal diameter of the conduit (in inches). Use manufacturer or standard table values for conduit type (EMT, Rigid, PVC).

- pi = 3.141592653589793

- D_id = 0.50 inch (nominal small conduit) → A_conduit = 0.19635 in²

- D_id = 0.75 inch → A_conduit = 0.44179 in²

- D_id = 1.00 inch → A_conduit = 0.78540 in²

- D_id = 1.25 inch → A_conduit = 1.22718 in²

- D_id = 1.50 inch → A_conduit = 1.76715 in²

- D_id = 2.00 inch → A_conduit = 3.14159 in²

Individual conductor apparent area (insulated)

Where:

- A_cond = apparent cross-sectional area of one insulated conductor (in square inches)

- D_ins = insulated conductor diameter (in inches). Use conductor insulation data (e.g., THHN, XHHW) or approximate by adding insulation thickness to bare conductor diameter.

| Conductor | Circular mils (cmil) | Bare area (in²) | Typical insulated diameter (D_ins, in) | Insulated area A_cond (in²) |

|---|---|---|---|---|

| AWG 14 | 4,110 | 0.00323 | 0.100 | 0.00785 |

| AWG 12 | 6,530 | 0.00513 | 0.120 | 0.01131 |

| AWG 10 | 10,380 | 0.00815 | 0.140 | 0.01539 |

| AWG 8 | 16,510 | 0.01296 | 0.170 | 0.02272 |

| AWG 6 | 26,240 | 0.02060 | 0.200 | 0.03142 |

| AWG 4 | 41,740 | 0.03278 | 0.260 | 0.05310 |

- Circular mil values are standard AWG approximations (rounded). Conversion: area (in²) = cmil * 0.0000007854.

- Insulated diameter values are typical for copper conductors with common insulation types (THHN/XHHW) and are representative, not manufacturer guarantees.

- Always confirm insulated diameter with cable datasheets for accurate installation planning.

Regulatory screening (code-based limits)

Before any probabilistic estimate, apply the established conduit-fill rules used in many codes (e.g., NFPA 70, NEC Chapter 9, and manufacturer tables). These rules provide deterministic maximums for conductor area as a fraction of conduit area.| Number of conductors | Maximum permitted fill (%) |

|---|---|

| One conductor | 53% |

| Two conductors | 31% |

| Three or more conductors | 40% |

- Compute total apparent conductor area: A_total = n * A_cond (if mixed sizes, sum each conductor's A_cond).

- Compute fill ratio f_code = 100% * A_total / A_conduit.

- Compare f_code with the permitted maximum from the table above. If f_code exceeds the permitted value, the run is noncompliant and must be redesigned.

Why regulatory screening may be insufficient

Code limits ensure safe heat dissipation and allow for a practical pulling space, but they are conservative and categorical. Even when code fill percentages are satisfied, mechanical jams can occur if localized packing concentrates conductors or if the fill approaches geometric jamming thresholds for randomly placed insulated cables. Therefore, a probabilistic screen complements regulatory checks to quantify residual risk and drive decisions (e.g., choose next larger conduit, use fewer conductors, or redesign with conductor bundling).Probabilistic jam model (engineering approximation)

This section describes a practical, implementable probabilistic model that screens risk based on occupancy (packing) relative to empirical jamming thresholds derived from circle-packing and random sequential adsorption (RSA) studies.Model rationale

Packing of equal circles into a circle has deterministic maximum packing densities under optimal arrangements (close packing). However, when conductors are placed randomly (as cables may shift and twist during pulling), the effective maximum packing fraction before a mechanical jam (an arrangement that blocks further movement) tends to be lower. For RSA of identical disks in a large plane, the jamming coverage is approximately 0.547. Confined circular boundaries and multimodal conductor diameters change the threshold; conservatively we use a design jamming threshold f_jam ≈ 0.55 (55% area occupancy) as a generic engineering limit for random placement of insulated conductors.Probabilistic estimator formula

Use the logistic-shaped estimator to map relative packing to probability of jam:

Where:

- P_jam = estimated probability of mechanical jam (value between 0 and 1)

- f_rel = f_actual / f_jam

- f_actual = A_total / A_conduit (dimensionless, not percent)

- f_jam = assumed jamming threshold (default 0.55)

- k = steepness factor (default 12). Larger k yields a steeper transition near f_rel = 1.

- If f_actual equals f_jam (f_rel = 1), P_jam = 0.5 for k finite: moderate chance of jam.

- For f_actual << f_jam, P_jam approaches 0 asymptotically; for f_actual >> f_jam, P_jam approaches 1.

- Choose f_jam and k based on site experience, cable types, and required conservatism. For high-consequence installations choose f_jam = 0.50 and k = 15 for a more conservative result.

Alternative statistical modifiers

If additional information is available, modify the model:- Use packing heterogeneity factor h (0 < h ≤ 1) to account for mixed conductor diameters or bundling; f_eff = h * f_actual. Suggested h: 0.9 for small diameter range, 0.8 for high variance.

- Apply lubrication/pulling-aid factor L (0 < L ≤ 1) reducing effective jam probability: P_jam_adj = P_jam * L. Typical L = 0.7 with proper lubrication and rollers, L = 0.4 with continuous inner lining or pulling systems.

- Include bend severity factor b (>1 increases P_jam) to penalize runs with many tight bends: adjust k or set f_jam = f_jam / b. Typical b: 1.0 straight, 1.2 mild bending, 1.5 tight bends near minimum bend radius.

Implementation workflow for a free probability calculator

This section provides the step-by-step algorithm any online or spreadsheet calculator should implement.Step-by-step algorithm

- Input conduit type and internal diameter (D_id) or select from a table of standard conduit sizes.

- Input each conductor type/count: conductor sizes (AWG or mm²), and insulation type (to determine D_ins). For mixed populations sum individually.

- Compute A_conduit using the conduit formula.

- Compute each A_cond = pi*(D_ins/2)^2 and sum to A_total.

- Compute code fill percentage f_code = 100% * A_total / A_conduit and report regulatory pass/fail vs NEC-style maxima.

- Compute f_actual = A_total / A_conduit (decimal form) and f_rel = f_actual / f_jam.

- Compute P_jam using the logistic formula. Apply modifiers h, L, b if available.

- Provide recommended actions when P_jam exceeds thresholds (e.g., >0.01, >0.10, >0.50), such as increase conduit size, reduce conductor count, parallel runs, or conduit-lining/pulling aids.

Example calculations (real cases)

At least two worked examples follow, showing full arithmetic and interpretative guidance.Example 1 — Ten THHN AWG 12 in 3/4" conduit (nominal ID = 0.75 in)

Assumptions:- Conduit internal diameter D_id = 0.75 in → A_conduit = pi*(0.75/2)^2

- Conductor: 10 × AWG 12 with typical insulated diameter D_ins = 0.120 in (THHN)

- Model parameters: f_jam = 0.55, k = 12, no modifiers (h = 1, L = 1, b = 1)

Step 1 — Conduit area:

A_conduit = pi * (0.75 / 2) * (0.75 / 2) = 3.1415926536 * 0.375 * 0.375 = 0.4417865 in²

Step 2 — Single conductor area:

Step 3 — Total conductor area:

Step 4 — Code fill percentage:

Step 5 — Probabilistic occupancy and jam probability:

exp(6.42) ≈ 0.00164? (Note: exp(6.42) is actually ~ 615; but we must be careful — check sign: exponent negative of -12*(f_rel-1) became positive; calculating correctly:)

Let's calculate carefully:exp(+6.42) ≈ 615.3

Example 2 — Six AWG 6 and four AWG 10 mixed in 1" conduit (nominal ID = 1.00 in)

Assumptions:- Conduit D_id = 1.00 in → A_conduit = pi*(1/2)^2 = 0.785398 in²

- Conductors: 6 × AWG 6 (D_ins = 0.200 in), 4 × AWG 10 (D_ins = 0.140 in)

- Model parameters: f_jam = 0.55, k = 12, heterogeneity factor h = 0.9 (mixed sizes), pulling aid L = 0.8 (good rollers)

Step 1 — Conduit area:

Step 2 — Single areas:

Step 3 — Total conductor area:

Step 4 — Code fill percentage:

Step 5 — Probabilistic occupancy and jam probability:

exp(5.7468) ≈ 313.76

Recommended thresholds and mitigations

Establish project-specific acceptance criteria for P_jam. Typical conservative thresholds:- P_jam < 0.01 (1%): Acceptable for routine installations.

- 0.01 ≤ P_jam < 0.10: Mitigate by pulling aids, reduce conductor count, or increase conduit size.

- P_jam ≥ 0.10: Redesign strongly recommended (choose larger conduit or parallel runs).

- Increase conduit size to the next standard internal diameter and re-evaluate.

- Split conductors across additional conduits or phases where practical.

- Use cable trays or larger ducts for long runs and large conductor counts.

- Employ continuous inner conduit lining, rollers, or low-friction pulls (reduces P_jam via L factor).

- Pre-assemble conductors into bundles with spacers to control layout (reduces h factor unpredictability).

Tables for quick screening

Use the following quick-reference table to estimate the maximum number of uniform THHN AWG12 conductors permissible by code and approximate jam risk screening in nominal conduits (assumes D_ins = 0.120 in). This table is a screening aid; verify with exact conduit manufacturer ID and conductor dimensions.| Nominal conduit ID (in) | A_conduit (in²) | Max # AWG12 by code (40% rule) | # AWG12 at jamming threshold (f_jam=0.55) | Practical recommended max (P_jam <1%) |

|---|---|---|---|---|

| 0.50 | 0.19635 | 6 | 8 | 5 |

| 0.75 | 0.44179 | 15 | 20 | 10 |

| 1.00 | 0.78540 | 28 | 39 | 22 |

| 1.25 | 1.22718 | 48 | 67 | 40 |

| 1.50 | 1.76715 | 92 | 130 | 75 |

| 2.00 | 3.14159 | 218 | 363 | 200 |

- Max # AWG12 by code estimated as floor(0.40 * A_conduit / A_cond). A_cond for AWG12 used = 0.01131 in².

- # at jamming threshold = floor(0.55 * A_conduit / A_cond).

- Practical recommended max approximates the count that keeps P_jam < 1% using the logistic estimator with k = 12.

- These numbers are illustrative; always check actual conduit ID and conductor insulation diameter with datasheets.

Validation and calibration

For best results:- Calibrate f_jam and k using empirical site data: record actual pull incidents vs computed P_jam to fit k and f_jam for local cables and practices.

- Run sensitivity studies varying h, L, and b for project risk assessment.

- Retain conservative margins for critical systems (life-safety, redundancy-required circuits).

Standards, references and further reading

Below are normative references and authoritative resources that inform these checks. Consult the most recent editions, and always use manufacturer data for final design.- NFPA 70, National Electrical Code (NEC) — Conduit fill rules and Chapter 9 tables. https://www.nfpa.org/

- IEC 60364 series — International electrical installation standards (conduit and wiring practice). https://www.iec.ch/

- American National Standards Institute (ANSI) and NEMA conduit standard information (conduit diameters and dimensions). https://www.nema.org/

- Manufacturer cable dimension tables, e.g., Southwire conduit fill tables and product datasheets. https://www.southwire.com/

- Research on random sequential adsorption and jamming thresholds: review articles and summaries: https://en.wikipedia.org/wiki/Random_sequential_adsorption and primary literature (e.g., J. Feder et al.).

- IEEE guide documents for installation practice and cable pulling tension guidance (IEEE Xplore). https://ieeexplore.ieee.org/

Practical notes for implementers of free calculators

If you are building an online or spreadsheet calculator to implement these checks, include:- Input validation: ensure D_id and D_ins are numeric and units are consistent.

- Default tables for common conduit sizes and conductor insulation diameters, with links to datasheets for verification.

- Options for conservative vs. nominal mode (allow user to select f_jam and k).

- Present both deterministic code-pass/fail and probabilistic P_jam with mitigation suggestions.

- Exportable reports with calculation steps to support field decisions and permit submittals.

Key takeaways for designers and installers

- Always perform deterministic conduit-fill checks (NEC-style) first. They are required and enforce minimum safety spacing.

- Use the probabilistic model to quantify residual risk of mechanical jamming — particularly useful when fill is moderate and pull complexity is high.

- Validate assumptions for insulated conductor diameters and conduit internal areas with manufacturer data.

- Select conservative thresholds for critical systems and calibrate the model with site experience.

- When in doubt, increase conduit size, split the run, or use dedicated pulling aids to reduce both jam probability and physical pulling stresses.