Accurate relay selection prevents equipment damage and optimizes protection coordination in power systems operation reliability.

Calculator features must include time-current curves, IDMT settings, pickup ratios, and adjustable time delays accurately.

Overcurrent Relay Selection Calculator — Recommended Pickup & CT Scaling

Fundamental principles and selection objectives for overcurrent protection

Overcurrent relays protect conductors, transformers, generators, motors and buswork by detecting excessive currents and initiating circuit interruption. Selection of an overcurrent relay calculator and the resulting relay settings must satisfy three primary objectives: safety (personnel and equipment), selectivity (coordination between devices), and stability (no nuisance tripping during transient events such as motor starting or inrush currents). Key protection types and terms:- Instantaneous overcurrent (IO): no intentional time delay; trips when current exceeds a preset multiple of pickup.

- Inverse definite minimum time (IDMT): trip time decreases as current magnitude increases, governed by a time multiplier setting (TMS) and curve shape.

- Definite-time overcurrent: fixed time delay independent of current magnitude above pickup.

- Pickup setting (Ip or Ipickup): the current level at which the relay begins timing or initiates trip.

- CT ratio and accuracy: current transformer ratio, burden and class affect relay input and must be included in calculator logic.

Core calculations required in a robust relay selection calculator

A professional calculator must implement these calculation modules:- Short-circuit current calculation (three-phase, single-line-to-ground, phase-to-phase) based on system impedances and fault location.

- Load current and continuous current margins for pickup selection.

- Time-current characteristic evaluation for IDMT and definite-time types.

- Coordination study between upstream and downstream protective devices, including minimum operating times and intentional time grading.

- CT selection and saturation study to ensure relay sees true fault currents within CT linear range.

- Motor starting/inrush discrimination: verification that starting currents do not cause unintended trips.

- Breaker interrupting time and curve overlay with relay operating times for final clearing time estimation.

Essential mathematical relationships (expressed in plain HTML text)

Three-phase symmetrical short-circuit current (balanced fault):

Variables:

- V_LL = line-to-line nominal voltage (V)

- Z_th = total Thevenin impedance seen from the fault point (ohm)

- I_sc = fault current magnitude (A)

- V_LL for medium-voltage feeders: 11,000 V; for low-voltage mains: 400 V

- Z_th often computed from substation short-circuit MVA: Z_th = V_LL^2 / (sqrt(3) × S_sc) converted appropriately

Phase current for single-line-to-ground and phase-to-phase faults requires sequence impedances and may be computed per IEC 60909 methodologies. For example, for single-line-to-ground:

Variables:

- V_ph = phase-to-neutral voltage (V)

- Z1, Z2, Z0 = positive, negative and zero sequence impedances (ohm)

IDMT generic equation implemented by many relays and calculators:

Variables:

- t = operating time (s)

- K, α = curve constants (dimensionless) depending on curve family

- TMS = time multiplier setting (dimensionless, often 0.05–2.0)

- I = measured current (A)

- Ir = relay pickup setting (A) or normalized pickup (often 1.0)

- TMS between 0.02 and 2.0 depending on coordination requirements

- Common curve families: inverse, very inverse, extremely inverse; K and α are manufacturer/scheme specific

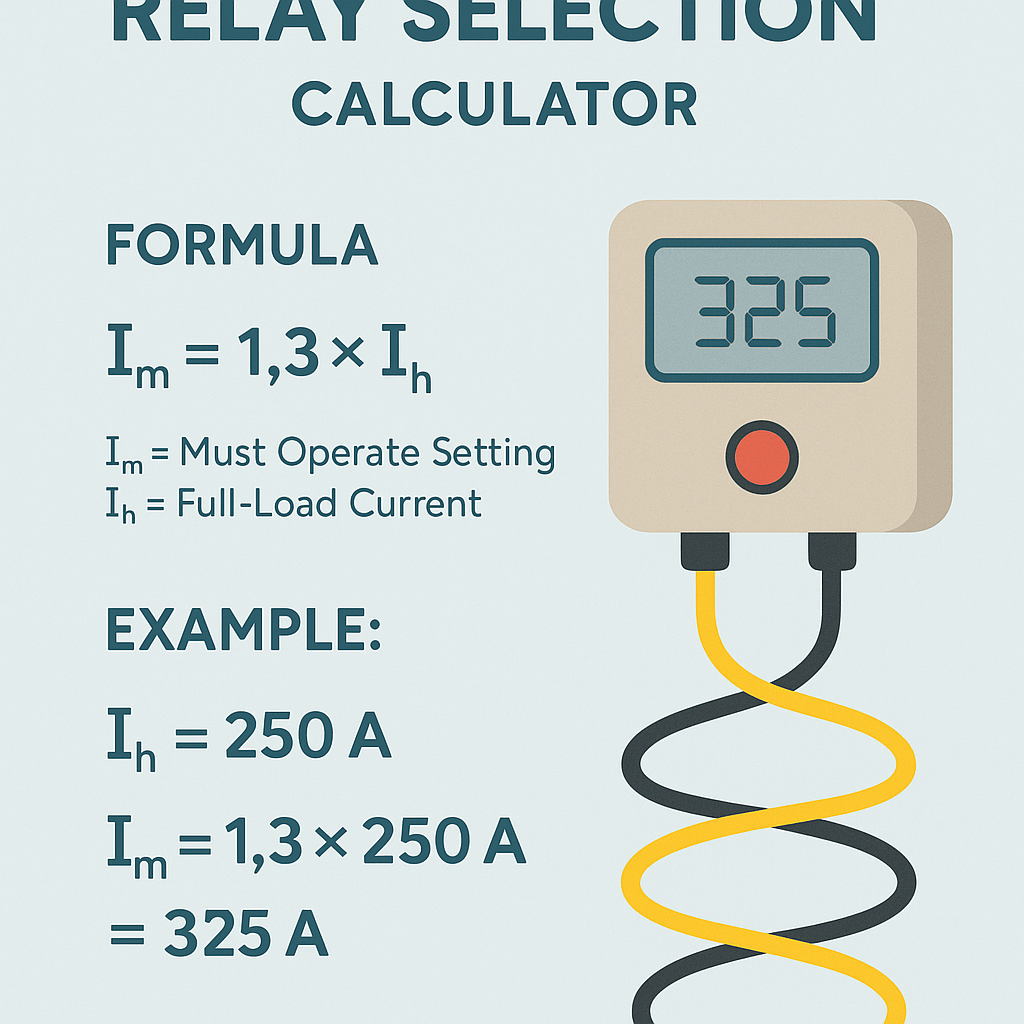

Pickup selection rule-of-thumb:

Variables:

- Ip = relay pickup current (A)

- I_load = maximum continuous load current (A)

- k_load = safety factor, commonly 1.1–1.25 for feeders carrying continuous loads

Instantaneous trip setting and coordination:

Variables:

- I_inst = instantaneous trip threshold (A)

- M_inst = instantaneous multiplier (3–12 typical)

- Ir = relay pickup setting (A)

Tables of common values for practical design and calculator presets

| Item | Typical Range / Value | Notes |

|---|---|---|

| Low-voltage system V_LL | 400 V, 480 V | Factory and building mains |

| Medium-voltage system V_LL | 6.6 kV, 11 kV, 13.8 kV | Distribution feeders |

| Typical CT ratios | 200/1, 400/5, 800/5, 1000/5 | Selected to match relay input and primary currents |

| Relay pickup multiplier (Ip / I_load) | 1.05 – 1.25 | Higher for non-continuous loads or harmonics |

| Instantaneous multiplier M_inst | 3 – 12 | Motor feeders typically higher to tolerate inrush |

| TMS typical range | 0.02 – 2.0 | Smaller TMS → faster trips |

| Time grading margin between devices | 0.3 – 0.5 s for LV; 0.2 – 0.5 s for MV | Depends on breaker operating times and coordination philosophy |

| Breaker arcing time additional allowance | 0.05 – 0.2 s | Added to relay operating time for total clearing time |

| Relay curve family (example) | Representative K | Representative α | Use case |

|---|---|---|---|

| Inverse (general) | 0.14 – 0.16 (typical) | 0.02 – 0.04 (illustrative) | General feeder protection |

| Very inverse | 1.0 – 3.0 (manufacturer dependent) | 0.5 – 1.0 | Protection for sources with large variations in fault current |

| Extremely inverse | 10 – 80 | 1.0 – 2.0 | Improved selectivity for short-range faults near transformer |

Calculator functional requirements and UX priorities

A best-in-class overcurrent relay selection calculator must provide:- User-friendly input forms for system data: voltage levels, transformer ratings and X/R, feeder impedances, cable lengths, breaker characteristics, CT ratios and burden.

- Multiple fault types supported (three-phase, single-line-to-ground, phase-to-phase) with sequence impedance handling or standardized IEC 60909 options.

- Built-in library of relay curves and allow upload of manufacturer curve data for precise overlays.

- Automated coordination diagrams (TCCs) with zoom, exportable data and suggested TMS/pickup candidates.

- CT saturation simulation and harmonic/inrush discrimination options for motor loads.

- Report generation containing normative references, calculation steps, and final settings exportable to CSV or IEC 61850 SCL templates where applicable.

Coordination algorithm essentials

Algorithmic steps that the calculator should perform:- Calculate prospective fault currents at each bus and feeder node.

- Estimate load currents and continuous duty margins; propose baseline pickup = k_load × I_load.

- Overlay relay TCCs using chosen curve families and initial TMS.

- Perform time grading checks: ensure relay downstream clears significantly faster than upstream relay plus grading margin.

- Iterate TMS and pickup using optimization (minimize total clearing time while maintaining selectivity).

- Validate CT ratios and secondary currents to ensure relay input is within range and CTs do not saturate for expected fault currents.

Detailed worked examples

Below are two full examples with step-by-step calculations demonstrating best-practice usage of a relay selection calculator.

Example 1 — Distribution feeder protection coordination (11 kV feeder)

Scenario:- Substation: 11 kV line voltage, transformer 40 MVA, 11/0.4 kV with X/R ratio known.

- Feeder: radial 11 kV feeder supplying an industrial area; load current maximum 360 A at 11 kV (per feeder).

- Downstream device: LV feeder breaker at 400 V with known clearing time 0.08 s; upstream device: feeder breaker at 11 kV with operating time 0.12 s.

- Available short-circuit power at substation (three-phase): 100 MVA (from utility data).

- CT on 11 kV feeder secondary (relay input) to be 5 A secondary full scale.

Given S_sc = 100 MVA (three-phase short-circuit power), V_LL = 11 kV.

Z_th = (V_LL^2) / (S_sc × 1000) — convert S_sc to kVA consistent units.

Correct consistent approach: For three-phase fault current magnitude:

Because S_sc (MVA) is related: I_sc = S_sc / (sqrt(3) × V_LL) with S_sc in VA.

I_sc = 100,000,000 / (sqrt(3) × 11,000) ≈ 100,000,000 / (1.732 × 11,000) ≈ 100,000,000 / 19,052 ≈ 5,250 A

So the prospective three-phase fault current at the substation bus is approximately 5.25 kA. Step 2 — Determine feeder fault currents accounting for feeder impedance (assume feeder impedance negligible relative to source for this example), so I_fault ≈ 5.25 kA at the head of feeder. Step 3 — Load current and pickup selection for relay at 11 kV feeder:Load I_load = 360 A.

Choose Ip = 1.2 × I_load = 432 A.

Relay secondary pickup Ir (in secondary amps) given CT ratio: choose CT 200/5 to match primary 360 A range.

Using CT 200/5: primary 200 A → secondary 5 A. For primary 432 A, secondary Ip_sec = 432 × (5 / 200) = 10.8 A.

Step 4 — Instantaneous setting for short-circuit protection:Assume M_inst = 6 to avoid nuisance trip for start-up or transients.

Pick inverse curve (manufacturer) and initial TMS = 0.4 to achieve clearing time for near faults faster than downstream device plus grading margin.

For a fault current magnitude, compute relay operating time using t = K × TMS / ( (I/Ir)^α − 1 ).

Assume manufacturer example constants: K = 0.14, α = 0.02 (illustrative). For fault at 5,250 A and pickup Ir = 432 A, I/Ir = 5,250 / 432 ≈ 12.15. Compute:First compute exponent term: 12.15^0.02 ≈ exp(0.02 × ln(12.15)) ≈ exp(0.02 × 2.498) ≈ exp(0.04996) ≈ 1.0512

Primary fault current 5,250 A → secondary = 5,250 × (5 / 200) = 131.25 A.

Confirm CT thermal limit and knee point; typical protection CTs rated for these transient currents if specified. If CT saturates, choose higher ratio or multi-ratio CT, or use numerical relay that can handle higher secondary currents. Result summary for Example 1:- Prospective fault current: ~5.25 kA

- Relay pickup Ip = 432 A primary (10.8 A secondary @ 200/5 CT)

- Instantaneous threshold approx 2,592 A primary (64.8 A secondary)

- IDMT TMS initial estimate 0.4 with curve constants provided yields approximate clearing time 1.09 s (subject to manufacturer curve).

- CT secondary fault current ~131 A — verify CT knee point and saturation for transient performance.

Example 2 — Motor feeder protection (400 V motor, large inrush)

Scenario:- Motor: 400 V, rated current I_motor = 350 A, locked-rotor (starting) current = 6 × I_motor = 2,100 A

- Supply short-circuit capacity at motor bus: 30 kA prospective three-phase

- Protection devices: electronic relay with IDMT plus instantaneous element; CT ratio to be chosen

Prospective fault at motor bus I_sc = 30 kA (given).

Step 2 — Choose pickup and instantaneous thresholds to avoid nuisance trips during starting:Set Ip = 1.25 × I_motor = 437.5 A to handle full load and supply fluctuations.

Instantaneous set to allow starting: motor start current 2,100 A; choose I_inst > 2,500 A to avoid tripping during start (safety margin), so I_inst ≈ 7.14 × I_motor ≈ 2,500 A (approximately 7.14 × rated).

Step 3 — CT selection:Choose CT 400/5, so secondary at rated motor current: I_sec_rated = 350 × (5/400) = 4.375 A. Secondary pickup for Ip = 437.5 A is Ip_sec = 437.5 × (5/400) = 5.46875 A.

Secondary instantaneous threshold I_inst_sec = 2,500 × (5/400) = 31.25 A.

Step 4 — IDMT time versus fault/current in a starting event:During starting, the current may be 2,100 A primary → I/Ir = 2,100 / 437.5 = 4.8.

Using example IDMT constants (manufacturer sample): K = 0.14, α = 0.02 and selecting TMS = 0.5:- Pickup Ip = 437.5 A primary (≈5.47 A secondary @ 400/5 CT)

- Instantaneous threshold ~2,500 A primary (≈31.25 A secondary)

- IDMT TMS = 0.5 yields starting discrimination (~2.19 s) and fast fault clearing for large faults (~0.79 s for IDMT, instantaneous faster for >2,500 A)

- CT selection ensures secondary currents are within relay input range; verify CT thermal and knee-point if fault currents can saturate.

Practical CT and relay interface considerations

Important CT and relay interface checks that a calculator must perform:- Calculate secondary current under maximum fault: I_sec_fault = I_fault × (CT_secondary / CT_primary).

- Compare I_sec_fault to CT continuous and short-duration ratings; ensure thermal withstand and knee-point are adequate.

- Estimate CT burden and verify relay input impedance plus cable burden do not exceed CT accuracy class limits.

- Check for multi-ratio CT options to provide both protection accuracy and metering flexibility.

Quantitative CT saturation check (simple approach)

A simplified saturation evaluation in the calculator can compute the expected secondary mmf and compare with CT knee point:If V_s approaches or exceeds CT knee-point voltage V_k (from CT datasheet), saturation may occur during high fault currents causing under-reading by the relay.

Variables explained:- I_sec = expected secondary fault current (A)

- relay_impedance = relay input impedance at 50/60 Hz (ohm)

- wiring_impedance = cable impedance in secondary circuit (ohm)

- V_k = CT knee-point voltage from manufacturer (V)

Regulatory and normative references

Key standards and references to support calculations and settings:- IEC 60255 — Electrical relays (general electromechanical and measuring relays). Reference: https://www.iec.ch

- IEC 60909 — Short-circuit currents in three-phase AC systems (calculation methods). Reference: https://www.iec.ch

- IEEE Std C37.2 — Electrical Power System Device Function Numbers, acronyms and contact designations. Reference: https://standards.ieee.org

- IEEE Std C37.112 — Guide for the application of time-overcurrent relays (provides curve definitions). Reference: https://standards.ieee.org

- NFPA 70 (NEC) — National Electrical Code for equipment ratings and installation practices. Reference: https://www.nfpa.org

- Manufacturer relay and CT datasheets — for curve constants, TMS behavior, CT knee point and thermal ratings.

Best-practice recommendations for the calculator and workflow

To be effective and compliant, the selection calculator should:- Start from measured system data or latest utility short-circuit study; do not rely on default magnitudes alone.

- Support manufacturer curve import so that relay-specific K and α constants are exact, not approximated.

- Provide automatic coordination optimization but allow manual override by engineer for edge cases.

- Include CT saturation simulation and automatic CT ratio suggestions based on fault current magnitudes.

- Export final settings to relay configuration formats and include a human-readable report documenting calculations and normative references.

- Allow sensitivity studies (e.g., varying system short-circuit MVA ±20%) to assess protection robustness to system changes.

Checklist for commissioning engineers

- Verify measured system voltages and actual fault level versus calculator inputs.

- Confirm CT wiring and polarity, CT secondary burden and relay input burden match calculations.

- Validate that time grading margins are respected when considering breaker operating times.

- Test relay pickup and time settings during commissioning with secondary injection tests.

- Document settings and obtain operational acceptance from system operator/utility if required.

Limitations, disclaimers and areas requiring engineering judgment

While a calculator speeds selection and provides consistency, there are limitations that require professional review:- Manufacturer-specific curve behavior and numerical relay logic (e.g., directional elements, harmonic blocking filters) must be validated beyond generic IDMT formulas.

- CT saturation modeling is complex; a simplified V_k comparison helps but detailed electromagnetic simulation may be required for edge cases.

- Standards evolve; always cross-check with the latest editions of IEC/IEEE standards and local codes (e.g., NFPA, national grid codes).

- Field conditions such as harmonics, DC offset in fault currents, and communication delays for remote trip schemes must be considered in coordination studies.

Further reading and authoritative resources

- IEC 60255 series — for relay performance and testing guidelines: https://www.iec.ch/standards

- IEC 60909 — guidelines for calculating short-circuit currents: https://www.iec.ch/standards

- IEEE Std C37.112 — Recommended practice for power-system relay coordination: https://standards.ieee.org/

- NFPA 70 (NEC) — electrical installation and equipment requirements: https://www.nfpa.org/NEC

- Manufacturer technical handbooks (e.g., Siemens, ABB, Schneider Electric, SEL) — for specific TCCs and CT datasheets (search vendor sites for relay product pages).

Closing operational notes for practitioners

A high-quality overcurrent relay selection calculator is an engineering tool that must integrate accurate system data, manufacturer curves, CT modeling and coordination optimization. Use the calculator to propose settings, but always apply engineering judgment, field verification and compliance with applicable standards before commissioning settings in live protection devices. References:- IEC 60255 — Electrical relays (IEC Webstore)

- IEC 60909 — Short-circuit current calculations (IEC Webstore)

- IEEE Std C37.112 — Guide for overcurrent relays (IEEE Xplore/standards)

- NFPA 70 — National Electrical Code (NFPA)

- Sample manufacturer pages: SEL (Schweitzer Engineering Laboratories), ABB Protection and Control, Siemens Protection Devices