Accurately converting VA to Amps is vital in electrical design, equipment sizing, and safety compliance.

It ensures efficient panel sizing, proper UPS selection, and adherence to industrial standards like NEC or IEC.

This guide explains VA to Amps conversion using formulas, extended tables, and real-world NEC and IEEE applications.

VA ↔ Amps Calculator

Common VA to Amps Conversion Table

Below is a detailed reference table for common VA values across standard voltage levels in both single-phase and three-phase systems. This table assumes a power factor of 1.0 (ideal condition).

Single-Phase (Power Factor = 1.0)

| Voltage (V) | 100 VA | 200 VA | 300 VA | 500 VA | 1000 VA | 2000 VA | 3000 VA | 5000 VA | 10000 VA |

|---|---|---|---|---|---|---|---|---|---|

| 110 V | 0.91 A | 1.82 A | 2.73 A | 4.55 A | 9.09 A | 18.18 A | 27.27 A | 45.45 A | 90.91 A |

| 120 V | 0.83 A | 1.67 A | 2.50 A | 4.17 A | 8.33 A | 16.67 A | 25.00 A | 41.67 A | 83.33 A |

| 208 V | 0.48 A | 0.96 A | 1.44 A | 2.40 A | 4.81 A | 9.62 A | 14.42 A | 24.04 A | 48.08 A |

| 220 V | 0.45 A | 0.91 A | 1.36 A | 2.27 A | 4.55 A | 9.09 A | 13.64 A | 22.73 A | 45.45 A |

| 240 V | 0.42 A | 0.83 A | 1.25 A | 2.08 A | 4.17 A | 8.33 A | 12.50 A | 20.83 A | 41.67 A |

| 277 V | 0.36 A | 0.72 A | 1.08 A | 1.80 A | 3.61 A | 7.22 A | 10.83 A | 18.05 A | 36.10 A |

Three-Phase (Line-to-Line, Power Factor = 1.0)

| Voltage (V) | 1000 VA | 2000 VA | 3000 VA | 5000 VA | 10000 VA | 15000 VA | 20000 VA | 30000 VA |

|---|---|---|---|---|---|---|---|---|

| 208 V | 2.78 A | 5.55 A | 8.33 A | 13.89 A | 27.78 A | 41.67 A | 55.56 A | 83.33 A |

| 220 V | 2.63 A | 5.25 A | 7.88 A | 13.13 A | 26.25 A | 39.38 A | 52.51 A | 78.76 A |

| 380 V | 1.52 A | 3.03 A | 4.55 A | 7.58 A | 15.15 A | 22.73 A | 30.30 A | 45.45 A |

| 400 V | 1.44 A | 2.89 A | 4.33 A | 7.22 A | 14.43 A | 21.65 A | 28.87 A | 43.30 A |

| 415 V | 1.39 A | 2.78 A | 4.17 A | 6.95 A | 13.89 A | 20.84 A | 27.78 A | 41.67 A |

| 480 V | 1.20 A | 2.40 A | 3.60 A | 6.00 A | 12.00 A | 18.00 A | 24.00 A | 36.00 A |

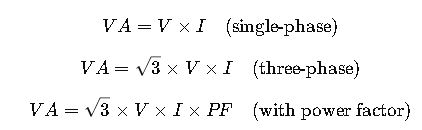

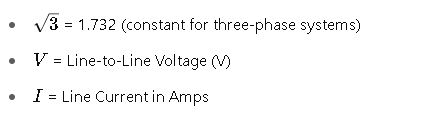

These values are based on √3 × V × I formula for three-phase and V × I for single-phase. Assumes power factor = 1.0.

Formulas for VA to Amps Conversion

VA and Amps are related by the voltage and the nature of the system (single-phase or three-phase). Here are the standardized formulas:

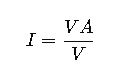

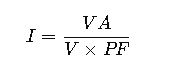

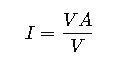

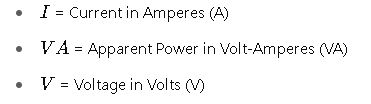

Single-Phase Formula

Where:

Typical Values:

- Residential voltages: 110V, 120V

- Commercial voltages: 208V, 220V, 240V

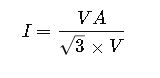

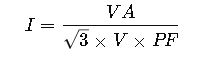

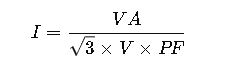

Three-Phase Formula (Line-to-Line Voltage)

Where:

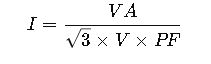

Three-Phase with Power Factor

Where:

- PF= Power Factor (dimensionless, typically 0.8–1.0 for industrial loads)

Rearranged for VA

Power Factor Reference:

- Resistive Loads (heaters, incandescent bulbs): PF = 1.0

- Inductive Loads (motors, transformers): PF ≈ 0.8–0.95

- Capacitive Loads (power factor correction): PF can exceed 1.0 in compensation scenarios

Real-World Examples of VA to Amps Conversion

To further understand the application of these formulas, let’s explore two real-world case studies using actual industrial and commercial equipment.

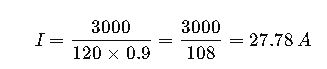

Example 1: Sizing a Single-Phase UPS for an Office Setup

Scenario:

An office plans to install a UPS (Uninterruptible Power Supply) system rated at 3000 VA to support a group of computers. The system operates on a 120V single-phase line. The power factor of the load is 0.9 (due to a mix of resistive and inductive loads such as monitors and small printers).

Given:

- VA=3000

- V=120V

- PF=0.9

Formula:

Calculation:

Result:

The UPS will draw 27.78 A from the supply under full load. This informs the breaker and conductor sizing for safe operation.

Compliance Check: Ensure that the circuit breaker and wiring are rated for at least 125% of the full load current, as per NEC Article 210 and 240.

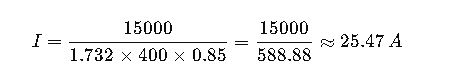

Example 2: Industrial Motor Load on a Three-Phase System

Scenario:

A facility operates a three-phase machine requiring 15,000 VA on a 400V supply. The motor’s power factor is 0.85.

Given:

- VA=15,000

- V=400V

- PF=0.85

Formula:

Calculation:

Result:

The motor will draw approximately 25.47 A from the system.

According to IEC 60204 and IEEE 141, proper selection of contactors, protection relays, and conductors must consider starting current (often 5–7× rated) and derating factors for temperature or grouping.

Practical Applications and Industry Relevance

Why Convert VA to Amps?

Converting VA to Amps is crucial in the following applications:

- UPS/Battery Backup Sizing

Correct amperage ensures battery autonomy and runtime match equipment demands. - Circuit Breaker Selection

Overcurrent devices (per NEC/IEC) must be rated above the expected amperage. - Generator and Transformer Sizing

Ratings in kVA require conversion to current to check cable sizes and voltage drop. - Energy Monitoring

Smart meters and energy management systems need accurate real-time current data for safety and optimization.

Power Factor Considerations

Not accounting for power factor can drastically affect current estimation:

| Power Factor | Effect on Current |

|---|---|

| 1.0 (ideal) | Baseline |

| 0.95 | +5.3% current |

| 0.90 | +11.1% current |

| 0.85 | +17.6% current |

| 0.80 | +25% current |

Poor power factor leads to oversized conductors, increased losses, and voltage drops. Power factor correction (capacitor banks) can mitigate these issues.

Voltage Tolerance and Standards

Voltage Standards by Region

| Region | Common Voltages (Single-Phase) | Common Voltages (Three-Phase) |

|---|---|---|

| North America | 110V, 120V | 208V, 480V |

| Europe | 220V, 230V | 400V, 415V |

| Latin America | 110V, 127V, 220V | 220V, 380V, 440V |

| Asia | 220V, 240V | 380V, 415V, 440V |

Reference: IEC 60038 – IEC Standard Voltages

Tools and Automation

To streamline engineering workflows, web-based calculators or mobile apps are increasingly used for these conversions.

Recommended Tools:

For rapid deployment, AI-powered calculators embedded in web platforms can offer real-time conversion with built-in safety and regulatory checks.

Safety and Regulatory Notes

- NEC 310.15(B): Ampacity adjustment based on ambient temperature and number of conductors.

- IEC 60364-5-52: Derating requirements for cable sizing in international systems.

- IEEE 141: Provides detailed load flow and system protection methodologies.

Always size conductors and protection based on worst-case current — not just nominal VA ratings.

Frequently Asked Questions – VA to Amps Calculator

What is the difference between VA and Amps?

VA (Volt-Amperes) is a measure of apparent power, representing the product of voltage and current in an AC system, regardless of phase alignment.

Amps (A) measure the current flow. The relationship between them depends on the system voltage and power factor. VA is often used to size transformers and UPS systems, while Amps are essential for conductor sizing and protective devices.

How do I convert VA to Amps in a single-phase system?

Use this formula:

Where:

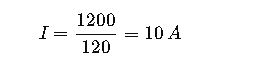

For example, 1200 VA at 120V:

How do I convert VA to Amps in a three-phase system?

Use this formula:

Where:

- V: Line-to-line voltage

- PF: Power factor (default = 1.0 if not known)

What is power factor and why does it matter?

Power Factor (PF) represents the ratio between real power (kW) and apparent power (kVA). A PF less than 1.0 indicates the presence of inductive or capacitive loads. A lower PF increases the current drawn, which may require thicker cables, higher-rated circuit breakers, and leads to higher energy costs. Typical industrial PF is 0.85–0.95.

Can I assume power factor is 1.0 for conversions?

Only for purely resistive loads (like heaters or incandescent lamps). Most real-world loads (motors, HVAC, fluorescent lighting) have PF < 1.0. For accurate current estimations, always use the actual PF provided by the equipment datasheet.

How does voltage affect VA to Amps conversion?

Higher voltage reduces the current for the same VA. For example, 5000 VA at 120V = 41.67 A, but at 240V = 20.83 A. That’s why industrial systems often use higher voltages: to reduce current, conductor size, and losses.

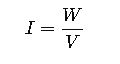

Can VA to Amps calculators be used for DC systems?

Not directly. DC systems don’t use VA; they use Watts (W). For DC:

However, for AC-powered equipment or systems rated in VA, the calculator applies.

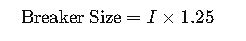

What size breaker do I need for a device rated in VA?

First, convert VA to Amps using the proper formula. Then multiply by a safety factor (typically 125% for continuous loads as per NEC 210.20(A)):

Always consult NEC tables or local codes.

Are kVA and VA the same?

Yes, but scaled.

- 1 kVA = 1000 VA

The conversion formulas are identical. Ensure you convert kVA to VA before plugging values into equations.

What are typical power factors for different equipment?

| Equipment Type | Typical Power Factor |

|---|---|

| Resistive Heaters | 1.00 |

| Induction Motors (Loaded) | 0.85 – 0.95 |

| Fluorescent Lighting | 0.70 – 0.90 |

| Computers and Servers | 0.90 – 0.98 (with PFC) |

| Welders | 0.35 – 0.75 |

Is this calculator compliant with electrical standards?

Yes, when used correctly. The calculator is based on IEC, NEC, and IEEE formula structures. For full compliance, always check:

- NEC 310.15(B) for ampacity

- IEC 60364-5-52 for international conductor sizing

- IEEE 141 (Red Book) for system design and load studies

Where can I find official resources?

Here are trusted references: