This technical guide addresses NEC 220.55 demand calculations for fast electrical cooking appliances precisely today.

Engineers and designers will find step-by-step calculators, examples, tables, and normative references included for practice.

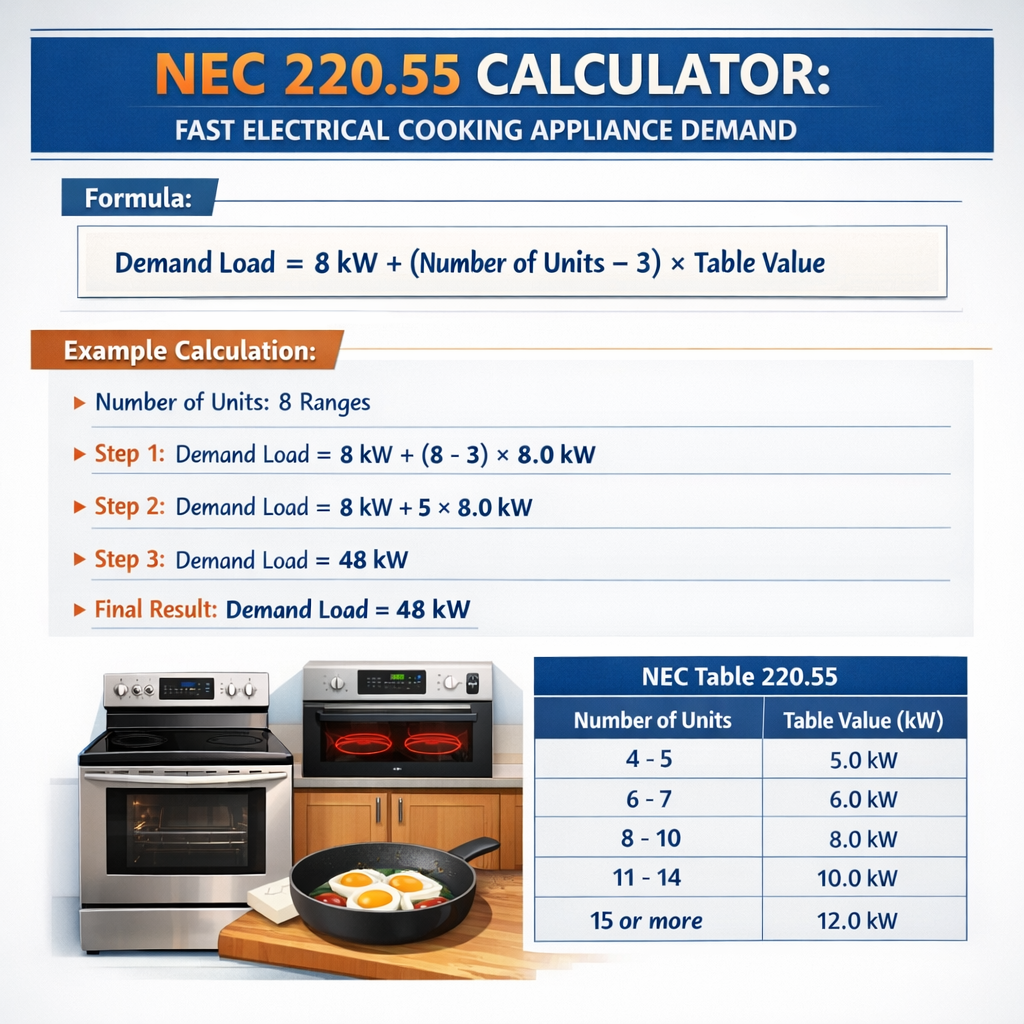

NEC 220.55 fast demand-load calculator for household electric ranges, ovens and cooktops

Scope and application of NEC 220.55 for cooking appliances

NEC 220.55 establishes methods to derive demand loads for household and similar electric ranges, wall-mounted ovens, and counter-mounted cooking units. The paragraph and corresponding table(s) provide demand values (in watts or kilowatts) for different counts and nameplate ratings of cooking appliances to allow sizing of service, feeders, and branch circuits.

This article focuses on engineering-safe methods to implement a calculator workflow for ranges, ovens, and cooktops, including conversion formulas, practical assumptions for voltage systems, examples, and references to the NEC and manufacturer data.

Fundamental electrical principles and formulas

Cooking appliances are largely resistive heating loads (power factor ≈ 1). The primary calculations convert between power (P, watts or kilowatts), current (I, amperes), and voltage (V, volts). When three-phase loads are present, branch between line-to-line and line-to-neutral terminology must be respected.

Basic formulas (single- and three-phase)

Variable explanations and typical values:

- P — real power in watts (W) or kilowatts (kW). Typical residential range: 6 kW–12 kW; commercial cooktop elements may be 10 kW–20 kW each.

- I — current in amperes (A).

- V — voltage. Typical single-phase residential service is 240 V nominal (North America). Typical three-phase commercial systems are 208 V (3Ø Wye) or 480 V (3Ø Delta/Y depending on site).

- PF — power factor. Heating elements PF ≈ 1. For motors or electronic controls, PF may deviate; use manufacturer data.

NEC 220.55 methodology and practical calculator architecture

NEC 220.55 provides demand values keyed to the number and individual nameplate ratings of cooking appliances. A practical calculator will:

- Collect nameplate ratings (kW) and the count of identical and non-identical units.

- Apply NEC 220.55 table lookup or, when units are mixed, aggregate using NEC directions: determine the demand for a set of units by grouping or using the table for the largest common rating, then add remainder as specified.

- Convert demand (kW) to current (A) at the applicable system voltage and phase using the formulas above.

- Include mandatory additional loads per other NEC sections: continuous loads (NEC 210.20, 215.3), appliance branch-circuit loads, and small-appliance loads if required.

Calculator logic outline

- Input: list of appliances with nameplate kW and quantity, supply voltage (e.g., 240 V single-phase, 208 V three-phase), inlet type (dedicated or grouped).

- Step: normalize nameplate ratings to kW (if given in BTU/hr or W).

- Step: use NEC 220.55 lookup (or validated table) to obtain demand kW for the specified quantity and rating bracket.

- Step: sum demands if multiple groups present.

- Output: total demand kW and converted current (A). Provide sizing recommendations for service, feeder, and branch circuit protective devices.

Tables: Typical nameplate ratings and conversion to current

| Appliance type | Typical nameplate rating (kW) | Current @ 240 V single-phase (A) | Current @ 208 V three-phase (A) (balanced, Pf=1) | Notes |

|---|---|---|---|---|

| Residential range (small) | 6.0 | 25.0 | — | Typical domestic small range, single-phase 240 V |

| Residential range (medium) | 8.8 | 36.7 | — | 8.8 kW common rating for many nameplates |

| Residential range (large) | 12.0 | 50.0 | — | Higher-end domestic ranges |

| Wall oven (single) | 4.5 | 18.8 | — | Single wall oven typical |

| Commercial cooktop element | 10.0 | 41.7 | 27.7 | Large element; three-phase 208 V current shown denominator using √3 |

| Commercial range or fryer | 20.0 | 83.3 | 55.5 | Heavy equipment requiring dedicated feeders |

Notes on the conversions in the table above:

- Single-phase current: I = (kW × 1000) / V. Example: 8.8 kW at 240 V → I = 8800 / 240 = 36.67 A.

- Three-phase current (balanced): I = (kW × 1000) / (√3 × VLL). Example: 10 kW at 208 V → I = 10000 / (1.732 × 208) ≈ 27.7 A.

Illustrative demand-factor table (calculator-friendly — verify against NEC)

The following table is an illustrative set of demand factors commonly used in engineering calculators to emulate NEC 220.55 behaviour for groups of similar appliances. This table is for example purposes only. Always verify final values against the edition of NEC applicable to the installation.

| Number of identical appliances | Illustrative demand factor (%) for total load | Illustrative applied method |

|---|---|---|

| 1 | 100% | Full nameplate load applied |

| 2 | 100% + 65% = 165% | First unit 100%, second unit 65% |

| 3 | 100% + 65% + 40% = 205% | Subsequent units reduced progressively |

| 4–6 | Progressively lower per additional unit | Applied per manufacturer or code table |

| More than 6 | Use NEC table lookup or aggregation rules | NEC 220.55 provides specific aggregation rules |

Important caveat

The NEC uses specific tabulated demand values and aggregation rules that depend on the individual appliance nameplate ratings and the number of appliances. The illustrative factors above are for demonstrating calculator methodology only. Always consult NEC Table 220.55 for compliance.

Step-by-step worked examples

Example 1 — Residential: Two mixed ranges and one wall oven (detailed)

Project: Single-family residence with the following fixed cooking appliances to be connected to the dwelling service:

- One 12.0 kW range (R1) — nameplate 12000 W

- One 8.8 kW range (R2) — nameplate 8800 W

- One 4.5 kW wall oven (O1) — nameplate 4500 W

Objective: Determine the demand load (kW) and the equivalent current for the dwelling service using NEC 220.55 methodology (illustrative approach with grouping rules and final conversion at 240 V single-phase).

Step A — Collect and normalize nameplate ratings:- R1 = 12.0 kW

- R2 = 8.8 kW

- O1 = 4.5 kW

- Sum of nameplate cooking loads = 12.0 + 8.8 + 4.5 = 25.3 kW

NEC 220.55 requires that ranges and ovens be considered per table values. When mixed ratings exist, the code allows grouping by using the highest common rating or separate lookups and summation as directed. For this worked example (illustrative), we will:

- Consider the two ranges as a group. Use an illustrative demand factor table: first range 100%, second range 65% (demonstration only).

- Apply 100% for the wall oven (it is a separate appliance type, but small ovens often are included with ranges depending on installation; for safety we'll treat it as an individual appliance at full nameplate for our conservative design).

- R1 demand portion = 12.0 kW × 100% = 12.0 kW

- R2 demand portion = 8.8 kW × 65% = 5.72 kW

- O1 demand portion = 4.5 kW × 100% = 4.5 kW

- Total illustrative demand = 12.0 + 5.72 + 4.5 = 22.22 kW

- I = (22.22 kW × 1000) / 240 V = 22220 / 240 ≈ 92.6 A

- Service and feeder selection must also include other loads (lighting, HVAC, small appliances) per NEC 220. For continuous loads apply the 125% factor where required.

- If the calculated cooking demand is 92.6 A, a standard 100 A service may be insufficient if additional loads push total above rating; consider 150 A service depending on aggregated load.

- The grouping method above is illustrative and conservative in the sense that we applied full nameplate to the largest unit and reduced subsequent units. The exact NEC Table 220.55 may yield a slightly different demand value; use the NEC table for final approval.

- Always include correction for continuous loads and feeders per NEC articles 215 and 220 when sizing protective devices and conductors.

Example 2 — Small commercial kitchen: Four identical 10 kW cooktops on 208 V three-phase

Project: Four identical cooktops, each nameplate 10 kW. Supply is 208 V 3Ø Wye. The layout has these four supplied from the same feeder.

Step A — List nameplate ratings and totals:- Each cooktop: 10 kW; quantity = 4

- Total nameplate connected = 10 × 4 = 40 kW

NEC 220.55 is primarily used for household ranges and similar; commercial kitchens often require full demand application or different code guidance (depending on installation). For demonstration, we will use an illustrative demand factor method specific to groups of similar commercial appliances (note: this is an engineering example — confirm with local code/authority).

Assumed illustrative demand factors:- First cooktop: 100%

- Second cooktop: 65%

- Third cooktop: 40%

- Fourth cooktop: 30%

- Cooktop 1: 10.0 kW × 100% = 10.0 kW

- Cooktop 2: 10.0 kW × 65% = 6.5 kW

- Cooktop 3: 10.0 kW × 40% = 4.0 kW

- Cooktop 4: 10.0 kW × 30% = 3.0 kW

- Total illustrative demand = 10.0 + 6.5 + 4.0 + 3.0 = 23.5 kW

- VLL = 208 V; P = 23.5 kW

- I = 23500 / (1.732 × 208) = 23500 / 360.256 ≈ 65.3 A

- Select a feeder with ampacity >65.3 A, and include 125% for continuous or sustained loads if required by other sections of code: feeder ampacity = 65.3 × 1.25 ≈ 81.6 A → choose 90 A or 100 A rated feeder conductors and protective device per conductor ampacity tables.

- Check motor or control devices on the cooktops that can introduce a non-unity PF—adjust calculations accordingly.

- Commercial cooking equipment often requires dedicated feeders with coordinated protection and may be treated differently by local code authorities. Use NEC 220.55 for household-type ranges and consult NEC 210 and equipment tables or local amendments for commercial gear.

Handling mixed rating groups and code-required aggregation

NEC 220.55 contains specific instructions for mixing appliances of different ratings. The usual approach is:

- Group identical appliances together and use table lookup for that rating and quantity.

- If multiple groups with differing ratings exist, compute the demand for each group separately and sum the demands.

- For remaining units not captured by table groupings, follow code rules for adding nameplate loads or applying a demand factor to the remainder.

Correct implementation requires access to the exact version of Table 220.55 for the applicable NEC cycle (e.g., NEC 2017, NEC 2020, NEC 2023) since table entries and commentary may change slightly between editions.

Calculator input validation, safety factors, and common pitfalls

- Validate nameplate data: ensure the kW rating is the heating element rating and not an input rating with duty cycle distinctions.

- Voltage selection: double-check whether the unit is rated for 240 V single-phase, 208 V three-phase, or other; incorrect voltage selection leads to wrong current conversions.

- Continuous loads: where appliances or combinations constitute continuous loads, apply 125% where the NEC requires.

- Concurrent loads: manufacturing data that gives multiple elements will sometimes represent total simultaneous heat versus typical duty. Use worst-case if sizing for safety.

- Harmonize with other NEC sections: loading calculations must be aggregated with lighting, HVAC, and small-appliance circuits per NEC 220 to size service and feeders properly.

Recommended outputs from a practical NEC 220.55 calculator

- Per-group demand in kW

- Total cooking demand in kW and W

- Total cooking current in amperes at specified voltage/phase

- Suggested minimum service and feeder ampacity (with notes on continuous load multipliers)

- Breakdown of applied code references (table entries used, version of NEC indicated)

- Flags for items requiring manufacturer input (e.g., non-heating loads, PF deviations)

Normative references and further authoritative resources

Key authoritative documents and links for NEC 220.55 and associated requirements:

- NFPA 70, National Electrical Code — consult the specific edition adopted in your jurisdiction. Official NFPA resources: https://www.nfpa.org/

- NEC Handbook commentary and tables — available from NFPA and professional code book vendors for detailed Table 220.55 values.

- UL product directories for appliance ratings and safety data: https://www.ul.com/

- ICC (International Code Council) and local authority having jurisdiction (AHJ) guidance — consult local amendments and interpretations: https://www.iccsafe.org/

- Manufacturers’ installation manuals and nameplate data for ranges, ovens, and cooktops — primary source for exact load values.

Best practices and engineering recommendations

- Always document the NEC edition used for the calculation and reference the specific Table 220.55 entry or code text that was applied.

- When in doubt, adopt the more conservative sizing for service and feeder ampacity to avoid nuisance tripping and to provide margin for future loads.

- Coordinate with the AHJ early in design for commercial kitchens, where local amendments may alter demand calculation procedures.

- Implement an audit trail in the calculator output: list nameplate inputs, grouped calculations, table source, and final conversion steps.

- If electronic controllers, timers, or other electronics are present on appliances, account for manufacturer-specified inrush, harmonics, or PF corrections when necessary.

Maintenance of a compliant calculator and traceability

To keep an engineering calculator compliant and defensible:

- Version-control the calculator and tag the NEC edition used for the lookup tables.

- Include a mechanism to store manufacturer nameplate snapshots with each project case.

- Log the assumed demand factors and whether they are illustrative, code-derived, or AHJ-approved.

- Provide a printable report that includes references to the specific NEC table entries used and the edition/year.

Summary of engineering steps (quick checklist)

- Collect appliance nameplate kW and quantities.

- Identify applicable NEC edition and Table 220.55 entries.

- Group identical appliances and apply table lookups per NEC guidance.

- Convert demand kW to amperes using single- or three-phase formulas.

- Aggregate with other loads per NEC 220 and apply continuous-load multipliers where required.

- Size feeders and protective devices using ampacity tables and 125% where applicable.

- Document all steps, assumptions, and references for AHJ review.

References and authoritative links

- NFPA. National Electrical Code (NEC) — most recent editions and official commentary. https://www.nfpa.org/NEC

- NEC Table 220.55 — see the NEC code book or digital access via NFPA for the authoritative table values and explanatory notes.

- UL Product iQ — lookup appliance listings and electrical data: https://iq.ulprospector.com/

- ICC — local code adoption and amendments: https://www.iccsafe.org/

Engineering note: The specific numeric results in worked examples above use illustrative demand factors to demonstrate methodology. For final design compliance, the exact Table 220.55 entries for the NEC edition adopted by the AHJ must be used and documented.