Electrical engineers, designers, and facility managers frequently require converting kilovolt-amperes (kVA) into watts (W). Conversions ensure accurate sizing of UPS systems, generators, industrial motors, hospital equipment, and critical data centers.

kVA ↔ Watts Calculator

Convert quickly between apparent power and real power using Power Factor (PF).

Which PF should I use?

Does phase change the formula?

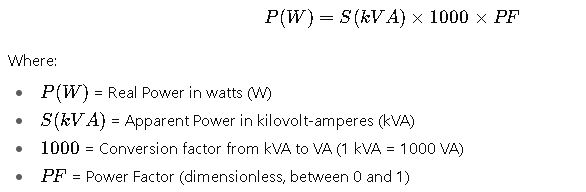

kVA to Watts Conversion Formula

The general formula to convert kVA to watts is:

Explanation of Variables

- Apparent Power (S, in kVA)

- Represents the total power flowing in the system.

- Includes both real power (watts) and reactive power (VAR).

- Common values for equipment range from 1 kVA for small UPS systems to 2000+ kVA for large industrial generators.

- Power Factor (PF)

- Ratio between real power and apparent power.

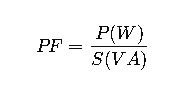

- Formula:

3.Typical PF values:

- Resistive loads (heaters, incandescent bulbs): PF ≈ 1.0

- Inductive loads (motors, transformers): PF ≈ 0.7 – 0.95

- Data centers / UPS systems: PF ≈ 0.8 – 0.9

Regulated by standards such as IEEE Std 141-1993 (Red Book) and IEC 60034.

4.Watts (W)

- Represents usable power that performs actual work.

- This is the parameter directly consumed by loads like lighting, HVAC systems, servers, and motors.

kVA to Watts Conversion Tables

The following tables provide ready-to-use conversion values for common kVA ratings at different power factors (0.6, 0.7, 0.8, 0.9, and 1.0). These are typical PF ranges seen in industry, data centers, and residential systems.

Table 1 – kVA to Watts Conversion at Different Power Factors

| kVA | Watts @ PF=0.6 | Watts @ PF=0.7 | Watts @ PF=0.8 | Watts @ PF=0.9 | Watts @ PF=1.0 |

|---|---|---|---|---|---|

| 1 | 600 W | 700 W | 800 W | 900 W | 1000 W |

| 2 | 1200 W | 1400 W | 1600 W | 1800 W | 2000 W |

| 3 | 1800 W | 2100 W | 2400 W | 2700 W | 3000 W |

| 5 | 3000 W | 3500 W | 4000 W | 4500 W | 5000 W |

| 7.5 | 4500 W | 5250 W | 6000 W | 6750 W | 7500 W |

| 10 | 6000 W | 7000 W | 8000 W | 9000 W | 10000 W |

| 15 | 9000 W | 10500 W | 12000 W | 13500 W | 15000 W |

| 20 | 12000 W | 14000 W | 16000 W | 18000 W | 20000 W |

| 25 | 15000 W | 17500 W | 20000 W | 22500 W | 25000 W |

| 30 | 18000 W | 21000 W | 24000 W | 27000 W | 30000 W |

| 40 | 24000 W | 28000 W | 32000 W | 36000 W | 40000 W |

| 50 | 30000 W | 35000 W | 40000 W | 45000 W | 50000 W |

| 75 | 45000 W | 52500 W | 60000 W | 67500 W | 75000 W |

| 100 | 60000 W | 70000 W | 80000 W | 90000 W | 100000 W |

| 150 | 90000 W | 105000 W | 120000 W | 135000 W | 150000 W |

| 200 | 120000 W | 140000 W | 160000 W | 180000 W | 200000 W |

| 250 | 150000 W | 175000 W | 200000 W | 225000 W | 250000 W |

| 300 | 180000 W | 210000 W | 240000 W | 270000 W | 300000 W |

| 400 | 240000 W | 280000 W | 320000 W | 360000 W | 400000 W |

| 500 | 300000 W | 350000 W | 400000 W | 450000 W | 500000 W |

| 750 | 450000 W | 525000 W | 600000 W | 675000 W | 750000 W |

| 1000 | 600000 W | 700000 W | 800000 W | 900000 W | 1000000 W |

| 1250 | 750000 W | 875000 W | 1000000 W | 1125000 W | 1250000 W |

| 1500 | 900000 W | 1050000 W | 1200000 W | 1350000 W | 1500000 W |

| 2000 | 1200000 W | 1400000 W | 1600000 W | 1800000 W | 2000000 W |

Table 2 – Focused Values for Data Centers and UPS Systems

These are the most common ratings used in critical IT infrastructure.

| UPS / Generator Size (kVA) | PF=0.8 (Industry Standard) | PF=0.9 (Modern UPS Systems) | PF=1.0 (High-Efficiency UPS) |

|---|---|---|---|

| 10 kVA | 8000 W | 9000 W | 10000 W |

| 20 kVA | 16000 W | 18000 W | 20000 W |

| 30 kVA | 24000 W | 27000 W | 30000 W |

| 50 kVA | 40000 W | 45000 W | 50000 W |

| 100 kVA | 80000 W | 90000 W | 100000 W |

| 250 kVA | 200000 W | 225000 W | 250000 W |

| 500 kVA | 400000 W | 450000 W | 500000 W |

| 1000 kVA | 800000 W | 900000 W | 1000000 W |

Importance of Power Factor in Conversion

- At PF = 1.0 → kVA equals watts (ideal case).

- At PF < 1.0 → Real power is lower, requiring larger kVA capacity for the same wattage.

- Regulatory authorities (like IEEE, IEC, and ANSI) require power factor correction in many installations.

Practical Applications of kVA to Watts Conversion

The conversion from kVA to watts is not merely a theoretical exercise. It has significant implications in power system design, electrical engineering, and equipment sizing. Below are some real-world contexts where this calculation is indispensable.

1. Data Centers and IT Infrastructure

Data centers are among the most power-intensive facilities in the modern world. Servers, storage arrays, and networking equipment require precisely calculated real power in watts.

- Why conversion is needed:

UPS (Uninterruptible Power Supply) systems and generators are typically rated in kVA. However, IT equipment manufacturers specify power demand in watts.

This mismatch requires engineers to perform kVA-to-watts conversion to ensure compatibility. - Example scenario:

A data center plans to install a 250 kVA UPS. The system has a power factor of 0.9.- Apparent Power = 250 kVA

- Real Power = 225,000 W (225 kW)

- Implication:

Oversizing or undersizing could either waste capital investment or lead to equipment failures. Correct conversion ensures efficiency, reliability, and compliance with standards like TIA-942 and ISO/IEC 30134.

2. Industrial Plants and Motor Loads

In heavy industries such as mining, oil refining, and manufacturing, electric motors dominate power consumption. Motors have an inherently lower power factor (often 0.7 to 0.85) due to their inductive nature.

- Why conversion is needed:

Most generators and transformers in industrial plants are rated in kVA. Engineers must determine how much real work (in watts or kilowatts) can be supported at the actual PF. - Example scenario:

An oil refinery operates a 1000 kVA generator with a power factor of 0.8.- Apparent Power = 1000 kVA

- Real Power = 800,000 W (800 kW)

- Implication:

Misjudging the real wattage capacity can lead to downtime, overheating, or equipment failure. By converting accurately, engineers align electrical infrastructure capacity with actual mechanical demand.

Real-World Case Studies

Case Study 1 – Hospital Emergency Power System

Hospitals rely heavily on backup generators to maintain life-saving equipment during outages. These generators are usually rated in kVA, but medical devices are specified in watts.

Scenario:

A mid-sized hospital is installing a 500 kVA generator. The expected power factor of the combined load (MRI machines, ventilators, HVAC, and lighting) is 0.85.

Step-by-step reasoning (simplified):

- Generator apparent capacity = 500 kVA

- Power factor = 0.85

- Real usable power = 500 × 1000 × 0.85 = 425,000 W (425 kW)

Interpretation:

This generator can reliably supply 425 kW of medical and facility load. Engineers will design load distribution panels accordingly, ensuring critical life-support systems have top priority.

Why this matters:

In healthcare, underestimating real power could mean insufficient supply for MRI systems or ventilators. Overestimating could waste millions on oversized generators. Accurate conversion balances cost with safety.

Case Study 2 – Commercial Office Tower with UPS

A modern office building requires uninterrupted power for elevators, fire alarms, and IT infrastructure. A UPS is chosen as the primary protection against outages.

Scenario:

The building installs a 300 kVA UPS rated at a power factor of 0.9.

Step-by-step reasoning (simplified):

- UPS apparent capacity = 300 kVA

- Real usable power = 270,000 W (270 kW)

Interpretation:

The UPS can safely supply 270 kW of real load to critical systems. Designers can size battery banks, switchgear, and distribution circuits based on this value.

Why this matters:

Without conversion, building managers might overload the UPS, risking shutdowns during an outage. Proper kVA-to-watts calculation ensures operational continuity, tenant safety, and compliance with building codes like NFPA 70 (NEC).

Extended Considerations in Conversion

Single-Phase vs. Three-Phase Systems

- Single-phase systems are common in residential and small commercial loads. Conversion is straightforward with one power factor applied.

- Three-phase systems, used in industrial plants and large buildings, require consideration of line voltage and load balancing, but the principle of kVA-to-watts remains the same: multiply by PF to determine usable watts.

Impact of Power Factor Correction

Power factor correction (PFC) devices—such as capacitor banks and active filters—are used to improve PF closer to 1.0.

- Without correction, a 1000 kVA generator at PF=0.7 delivers only 700 kW.

- With correction to PF=0.95, the same generator can supply 950 kW.

This demonstrates how PFC allows facilities to maximize usable wattage without upgrading equipment capacity.

Standards and Compliance

Several international standards govern how kVA and watt ratings are applied:

- IEEE Std 1459-2010: Defines active, reactive, and apparent power.

- IEC 60034: Specifies efficiency and power factor standards for electric motors.

- NFPA 110: Emergency power systems for healthcare and mission-critical facilities.

These standards ensure uniformity, safety, and performance reliability worldwide.

Why Accurate Conversion Matters

- Cost Efficiency – Oversized equipment wastes capital, while undersized equipment risks outages.

- Energy Efficiency – Correctly rated systems avoid losses due to low PF.

- Safety – Prevents overheating, tripping, and equipment damage.

- Regulatory Compliance – Many regions mandate minimum PF values.

- Operational Continuity – Ensures critical loads in hospitals, data centers, and industrial plants always receive sufficient power.

Authoritative References

For further technical depth, see:

- IEEE Standards Association – Guidelines on power factor and power measurement.

- IEC – International Electrotechnical Commission – Standards for motors, transformers, and power systems.

- NFPA 70 – National Electrical Code – Electrical safety and emergency system requirements.

- U.S. Department of Energy – Resources on power factor correction and energy efficiency.