Determining the correct conductor cross-section is critical for electrical safety and efficiency in power systems. This calculation ensures conductors handle current without overheating or excessive voltage drop.

This article explores conductor sizing based on current density per IEC and IEEE standards, providing formulas, tables, and practical examples. Engineers and designers will gain comprehensive insights for accurate conductor selection.

Artificial Intelligence (AI) Calculator for “Conductor Cross-Section by Current Density Calculator – IEC, IEEE”

- Calculate conductor size for 150 A current using IEC current density values.

- Determine cross-section for 200 A with IEEE standard current density.

- Find conductor area for 100 A in a three-phase system per IEC guidelines.

- Compute minimum conductor size for 250 A based on IEEE current density limits.

Common Current Density Values and Corresponding Conductor Cross-Sections

Current density (J) is the current per unit cross-sectional area of a conductor, typically expressed in A/mm². Both IEC and IEEE standards provide recommended current density values to ensure safe operation without overheating.

| Standard | Conductor Material | Typical Current Density (A/mm²) | Recommended Cross-Section (mm²) for 100 A | Notes |

|---|---|---|---|---|

| IEC 60287 | Copper | 2.5 | 40 | Standard installation, ambient 30°C |

| IEC 60287 | Aluminum | 1.5 | 70 | Standard installation, ambient 30°C |

| IEEE Std 835 | Copper | 3.0 | 35 | Typical power cable rating |

| IEEE Std 835 | Aluminum | 1.8 | 55 | Typical power cable rating |

| IEC 60364 | Copper | 2.0 | 50 | Building wiring, general purpose |

| IEC 60364 | Aluminum | 1.2 | 85 | Building wiring, general purpose |

Additional Practical Current Density Values for Various Applications

| Application | Conductor Material | Current Density (A/mm²) | Typical Cross-Section (mm²) for 100 A | Remarks |

|---|---|---|---|---|

| Overhead Lines | Aluminum | 1.0 | 100 | High ambient temperature, derating applied |

| Industrial Power Cables | Copper | 2.8 | 36 | High load, continuous operation |

| Residential Wiring | Copper | 2.0 | 50 | Short runs, moderate ambient temperature |

| Motor Feeders | Aluminum | 1.4 | 72 | Intermittent duty, thermal cycling considered |

Fundamental Formulas for Conductor Cross-Section Calculation

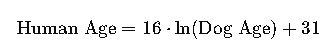

Calculating the minimum conductor cross-sectional area (A) based on current density involves the following primary formula:

- A = Conductor cross-sectional area (mm²)

- I = Current to be carried by the conductor (A)

- J = Current density (A/mm²), as per IEC or IEEE standards

This formula assumes steady-state current and standard ambient conditions. Adjustments may be necessary for temperature, installation method, and conductor grouping.

Voltage Drop Considerations

Voltage drop (Vd) is a critical factor in conductor sizing, especially for long runs. It is calculated as:

- Vd = Voltage drop (Volts)

- I = Load current (Amperes)

- L = One-way conductor length (meters)

- R = Conductor resistance (Ohms per km)

Resistance (R) depends on conductor material and cross-section:

- ρ = Resistivity of conductor material (Ohm·mm²/m)

- A = Cross-sectional area (mm²)

Typical resistivity values at 20°C:

- Copper: 0.0175 Ohm·mm²/m

- Aluminum: 0.028 Ohm·mm²/m

Temperature Correction Factor

Conductor resistance increases with temperature. The corrected resistance RT at temperature T (°C) is:

- RT = Resistance at temperature T

- R20 = Resistance at 20°C

- α = Temperature coefficient of resistivity (Copper: 0.00393 /°C, Aluminum: 0.00403 /°C)

- T = Operating temperature (°C)

Step-by-Step Real-World Example 1: IEC-Based Conductor Sizing for a 150 A Load

An industrial facility requires a copper conductor to carry 150 A continuously. The installation is indoors with an ambient temperature of 30°C. Using IEC 60287, the recommended current density for copper is 2.5 A/mm².

- Step 1: Calculate minimum cross-sectional area using A = I / J

- Step 2: Select the nearest standard conductor size equal or greater than 60 mm² (e.g., 70 mm²)

- Step 3: Verify voltage drop for a 100 m cable run at 70 mm²

Resistance of copper at 20°C for 70 mm²:

Voltage drop:

For a 400 V system, voltage drop percentage:

This is within typical acceptable limits (usually <3%), confirming the conductor size is adequate.

Step-by-Step Real-World Example 2: IEEE-Based Aluminum Conductor Sizing for a 200 A Load

A commercial building requires an aluminum conductor to supply 200 A. According to IEEE Std 835, the recommended current density for aluminum is 1.8 A/mm².

- Step 1: Calculate minimum cross-sectional area:

- Step 2: Choose the next standard conductor size, 120 mm²

- Step 3: Calculate resistance at 20°C:

- Step 4: Calculate voltage drop for 150 m cable length:

Voltage drop percentage for a 415 V system:

This is acceptable for most commercial installations, confirming the conductor size is suitable.

Additional Technical Considerations for Conductor Sizing

- Ambient Temperature: Higher temperatures reduce current carrying capacity; apply correction factors accordingly.

- Grouping of Conductors: Multiple cables bundled together require derating due to reduced heat dissipation.

- Installation Method: Conductor in conduit, buried, or free air affects thermal dissipation and current density limits.

- Short-Circuit Ratings: Mechanical strength and thermal withstand must be verified for fault currents.

- Harmonics and Load Type: Non-linear loads may increase conductor heating; consider derating or oversizing.

Summary of Key IEC and IEEE Standards for Conductor Sizing

| Standard | Scope | Relevant Sections | Key Parameters |

|---|---|---|---|

| IEC 60287 | Electric cables – Calculation of current rating | Part 1-1: Current rating calculation | Current density, thermal resistivity, installation conditions |

| IEC 60364 | Electrical installations of buildings | Part 5-52: Selection and erection of electrical equipment | Conductor sizing, voltage drop, protection coordination |

| IEEE Std 835 | IEEE Guide for Power Cable Ampacity Calculations | Entire document | Current density, temperature correction, cable construction |

Practical Tips for Using the Conductor Cross-Section Calculator

- Always verify the installation environment and adjust current density accordingly.

- Use standard conductor sizes available in the market to simplify procurement.

- Consider future load growth and select a conductor size with margin.

- Check voltage drop limits per local regulations or project specifications.

- Consult manufacturer datasheets for precise conductor resistance and thermal ratings.

By integrating IEC and IEEE standards with practical engineering judgment, the conductor cross-section calculator becomes an indispensable tool for electrical design professionals. Accurate sizing ensures safety, efficiency, and longevity of electrical installations.

For further reading and official standards, visit the IEC official website and the IEEE Standards Association.