Accurately calculating packaging material weight is crucial across industries, such as logistics, manufacturing, and environmental compliance. This comprehensive guide delivers expert insights on methodologies, formulas, and real-world applications for packaging weight.

Packaging Material Weight Calculator

How is the total weight calculated?

What if material type is “Other”?

Common Packaging Material Weights

Understanding the typical weights of various packaging materials is crucial for accurate calculations. Below is a comprehensive table detailing the average weights per unit area or volume for common packaging materials:

| Material Type | Unit of Measure | Average Weight (g) | Notes |

|---|---|---|---|

| Cardboard (Single Wall) | g/m² | 300–600 | Commonly used for shipping boxes. |

| Corrugated Fiberboard | g/m² | 500–900 | Offers higher durability for heavy items. |

| Plastic Film (LDPE) | g/m² | 15–50 | Lightweight and flexible. |

| Plastic Film (HDPE) | g/m² | 20–60 | Strong and resistant to impact. |

| Polyethylene Bags | g/unit | 5–50 | Varies based on size and thickness. |

| Glass Bottles | g/unit | 200–500 | Heavier due to material density. |

| Metal Cans | g/unit | 150–350 | Common for beverages and food products. |

| Wooden Crates | kg/unit | 5–20 | Used for bulk shipping of heavy goods. |

| Paperboard Boxes | g/m² | 200–400 | Standard for retail packaging. |

| Foam Inserts | g/unit | 10–100 | Protective packaging for fragile items. |

These values serve as general guidelines and can vary based on specific material grades and manufacturing processes.

Formulas for Calculating Packaging Weight

Accurate calculation of packaging weight involves understanding the relevant formulas and variables. Below are the primary formulas used in the industry:

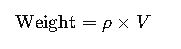

1. Weight of Packaging Material (General Formula)

Where:

- ρ= Density of the material (g/cm³)

- V = Volume of the material (cm³)

This formula is fundamental for calculating the weight of packaging materials based on their density and volume.

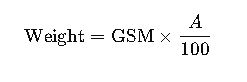

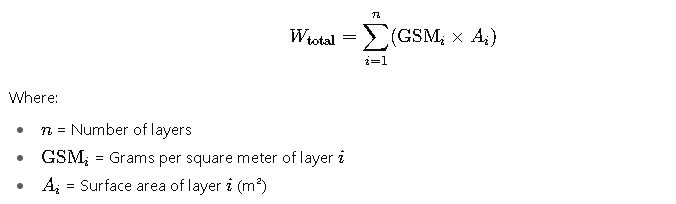

2. Weight Based on Surface Area (For Films and Sheets)

Where:

- GSM= Grams per square meter (unit weight of the material)

- A= Area of the material (m²)

This formula is applicable for materials like plastic films and paperboard, where the weight is determined by the area covered.

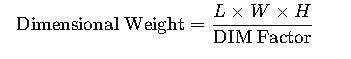

3. Dimensional Weight (For Shipping Calculations)

Where:

- L= Length of the package (cm)

- W = Width of the package (cm)

- H= Height of the package (cm)

- DIM Factor = Carrier-specific divisor (e.g., 5000 for some carriers)

This calculation is crucial for determining shipping costs, as carriers often charge based on dimensional weight rather than actual weight.

Real-World Examples

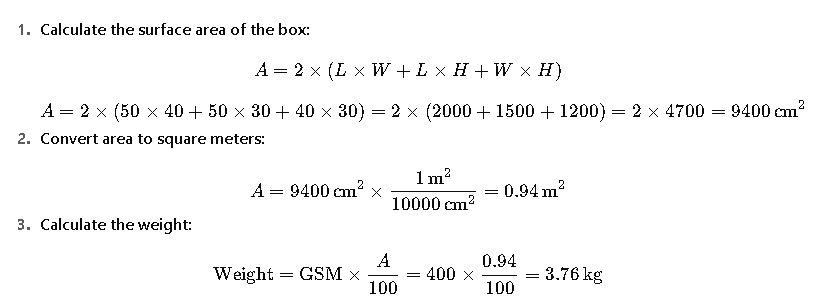

Example 1: Calculating the Weight of a Cardboard Box

Scenario: A company manufactures cardboard boxes with dimensions 50 cm x 40 cm x 30 cm. The cardboard has a GSM of 400. Calculate the weight of one box.

Solution:

Conclusion: The weight of one cardboard box is 3.76 kg.

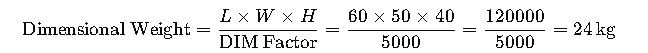

Example 2: Calculating Dimensional Weight for Shipping

Scenario: A package has dimensions 60 cm x 50 cm x 40 cm. The carrier’s DIM factor is 5000. Calculate the dimensional weight.

Solution:

- Calculate the dimensional weight:

Conclusion: The dimensional weight of the package is 24 kg.

Advanced Formulas for Packaging Weight Calculation

In addition to basic formulas, advanced considerations include multi-layer packaging, composite materials, and nested packaging designs.

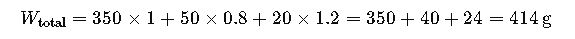

1. Weight of Multi-Layer Packaging

Example:

A package has three layers:

- Outer cardboard: GSM 350, area 1 m²

- Foam insert: GSM 50, area 0.8 m²

- Plastic wrap: GSM 20, area 1.2 m²

Thus, the total weight is 414 g.

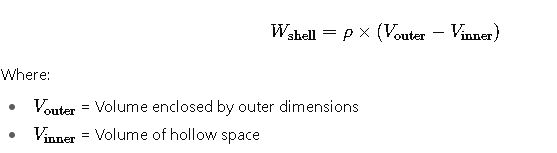

2. Weight of Hollow Containers (Shells)

For packaging like plastic bottles, metal cans, or corrugated boxes, only the shell contributes to weight:

Example:

A cylindrical plastic container:

- Outer radius: 5 cm, height: 20 cm

- Wall thickness: 0.5 cm

- Density of plastic: 0.95 g/cm³

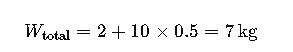

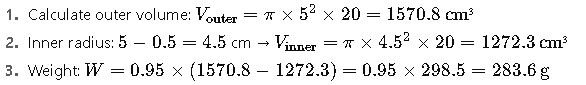

3. Nested Packaging Weight

For multiple products packed together:

Example:

- Outer cardboard box: 2 kg

- Each product with individual packaging: 0.5 kg

- Number of units: 10

Extensive Table of Material Densities and GSM

| Material Type | Density (g/cm³) | GSM Range (g/m²) | Notes |

|---|---|---|---|

| Single Wall Cardboard | 0.7 | 300–600 | Standard shipping boxes |

| Corrugated Fiberboard | 0.75–0.9 | 500–900 | Heavy-duty shipments |

| LDPE Film | 0.91 | 15–50 | Flexible plastic wraps |

| HDPE Film | 0.95 | 20–60 | Rigid and strong film |

| PET Sheet | 1.37 | 100–250 | Bottles and clamshells |

| Polypropylene (PP) Film | 0.9 | 20–80 | Durable packaging film |

| Glass | 2.5 | N/A | Heavy, rigid packaging |

| Steel | 7.85 | N/A | Metal cans, drums |

| Aluminum | 2.7 | N/A | Lightweight cans |

| Foam (Polyurethane) | 0.02–0.05 | N/A | Protective inserts |

Real-World Applications

Case 1: E-commerce Shipping Optimization

A company ships 500 units per day using cardboard boxes and polybag packaging. Accurate weight calculation ensures compliance with carrier dimensional weight pricing.

Data:

- Polybag per unit: 10 g

- Cardboard box for 10 units: 400 g

- Number of boxes: 50

Calculation:

- Polybag total: 500×10=5000 g = 5 kg

- Cardboard total: 50×400=20,000 g = 20 kg

- Total packaging weight: 25 kg

Outcome: Cost-efficient packaging reduces carrier fees and improves sustainability metrics.

Case 2: Industrial Product Shipping

A manufacturer ships fragile electronic devices using multi-layer packaging: foam inserts, cardboard boxes, and outer shrink-wrap.

Data:

- Device packaging: foam 50 g, cardboard 300 g, shrink-wrap 20 g

- Units per box: 5

- Boxes per shipment: 100

Calculation:

- Weight per unit packaging: 50+300+20=370g

- Weight per box: 5×370=1850g=1.85kg

- Total shipment weight: 100×1.85=185kg

Outcome: Ensures accurate shipping cost estimation and compliance with logistics standards.

Best Practices for Accurate Weight Calculation

- Measure Material Properties Precisely: Use manufacturer specifications for density and GSM.

- Include All Packaging Components: Foam inserts, tapes, labels, and protective films impact total weight.

- Consider Dimensional Weight for Shipping: Often higher than actual weight, affecting costs.

- Regularly Update Data: Material specifications change over time; maintain updated tables.

- Use Industry Standards: ISO 3394 for paperboard and ISO 536 for paper and cardboard weights.