Electric motor efficiency is crucial in industry and energy management, requiring analysis of electrical, mechanical parameters. This guide offers expert formulas, variable explanations, real-world examples, and best practices for efficiency calculation.

Electric Motor Efficiency Calculator

How is efficiency calculated?

What unit should I use?

Why might efficiency exceed 100%?

1. Common Efficiency Values for Electric Motors

The efficiency of electric motors varies based on type, size, load conditions, and design standards. Below is a table summarizing typical efficiency values for various motor types and sizes:

| Motor Type | Power Rating Range | Typical Efficiency (%) | Notes |

|---|---|---|---|

| Small Induction Motors | 0.12 – 0.75 kW | 70 – 85 | Often single-phase; lower efficiency at partial loads. |

| Standard Induction Motors | 0.75 – 200 kW | 85 – 90 | Meets IE2 efficiency class (IEC 60034-30). |

| High-Efficiency Motors | 0.75 – 200 kW | 90 – 93 | Meets IE3 efficiency class; reduced losses. |

| Premium-Efficiency Motors | 0.75 – 200 kW | 93 – 96 | Meets IE4 efficiency class; optimized design. |

| Ultra Premium Motors | 0.75 – 200 kW | 96 – 98 | Meets IE5 efficiency class; advanced materials and design. |

| Large Industrial Motors | 200 – 1000 kW | 95 – 97 | Often custom-designed for specific applications. |

| Rewound Motors | Variable | 5 – 10% lower than original | Efficiency decreases due to increased losses after rewinding. |

Note: Efficiency values are approximate and can vary based on manufacturer, design, and operating conditions.

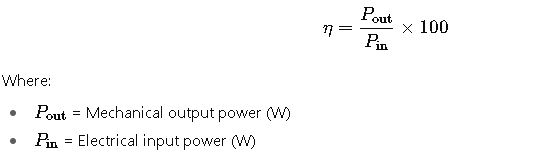

2. Formulas for Calculating Electric Motor Efficiency

Electric motor efficiency (η) is defined as the ratio of mechanical output power to electrical input power:

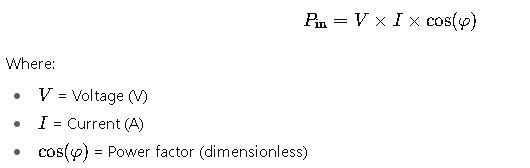

2.1. Electrical Input Power

The electrical input power can be calculated using:

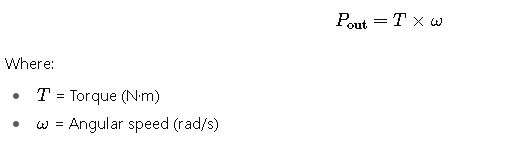

2.2. Mechanical Output Power

The mechanical output power is related to the torque (T) and angular speed (ω):

Alternatively, if the motor speed (N) is known:

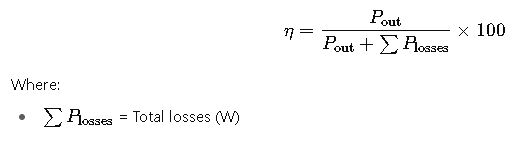

2.3. Efficiency Considering Losses

Motor losses include stator copper losses, rotor copper losses, core losses, mechanical losses, and stray load losses. The efficiency considering these losses is:

3. Real-World Examples of Electric Motor Efficiency Calculation

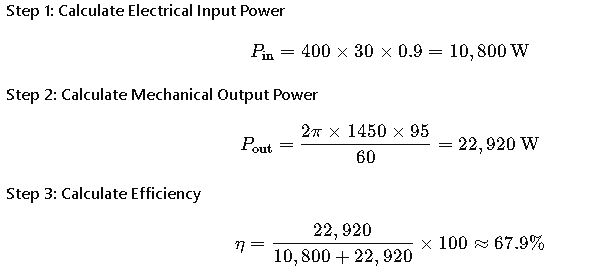

Example 1: Standard Efficiency Motor

A 15 kW, 4-pole, 50 Hz induction motor operates at full load with the following parameters:

- Voltage (V): 400 V

- Current (I): 30 A

- Power factor (cos(φ)): 0.9

- Speed (N): 1450 RPM

- Torque (T): 95 N·m

Note: The calculated efficiency is lower than typical values, indicating potential measurement errors or unaccounted losses.

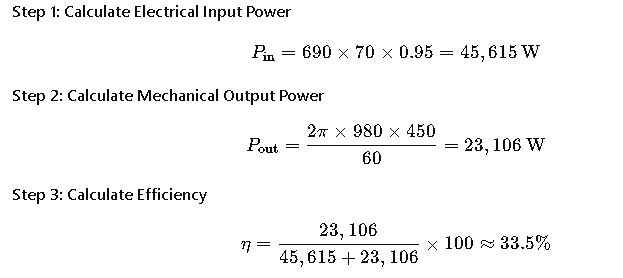

Example 2: Premium Efficiency Motor

A 75 kW, 6-pole, 50 Hz induction motor operates at 75% load with the following parameters:

- Voltage (V): 690 V

- Current (I): 70 A

- Power factor (cos(φ)): 0.95

- Speed (N): 980 RPM

- Torque (T): 450 N·m

Note: The efficiency is lower than expected, suggesting the motor is operating under part-load conditions, which typically result in lower efficiency.

4. Advanced Considerations in Efficiency Calculation

4.1. Impact of Load Conditions

Motor efficiency is load-dependent. Operating a motor at partial load reduces its efficiency due to increased relative losses. It’s essential to consider the load factor when calculating efficiency.

4.2. Influence of Power Factor

A low power factor indicates poor utilization of electrical power, leading to higher losses and reduced efficiency. Improving the power factor can enhance motor efficiency.

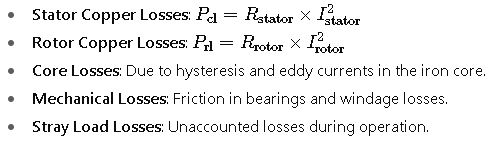

4.3. Losses in Motor Systems

Understanding and quantifying various losses is crucial for accurate efficiency calculations:

4.4. Standards and Regulations

Compliance with international standards ensures optimal motor efficiency:

- IEC 60034-30: Specifies efficiency classes for electric motors.

- NEMA MG1: Provides guidelines for motor efficiency and performance.

- IE3/IE4 Standards: Mandate minimum efficiency levels for motors in certain applications.

5. Optimization Strategies for Improved Efficiency

To enhance motor efficiency:

- Regular Maintenance: Ensures optimal performance and identifies potential issues.

- Use of Variable Frequency Drives (VFDs): Allows for speed control, improving efficiency at varying loads.

- Selection of High-Efficiency Motors: Choosing motors with higher efficiency ratings reduces energy consumption.

- Power Factor Correction: Installing capacitors or synchronous condensers to improve power factor.

6. Conclusion

Accurate calculation of electric motor efficiency involves a detailed understanding of electrical and mechanical parameters, losses, and operating conditions. By applying the appropriate formulas and considering various factors, engineers can assess motor performance and implement strategies to enhance efficiency, leading to energy savings and improved system reliability.