A UPS is vital to maintain continuous power during outages, voltage sags, and transient electrical events.

Correct battery sizing ensures autonomy, prevents over-discharge, optimizes costs, and meets IEEE and IEC standards.

UPS Battery Sizing Calculator — IEEE/IEC (English)

Calculate required battery capacity (Ah), series & parallel battery counts and total runtime factors. Includes inverter/rectifier efficiency, depth-of-discharge and derating.

Core Variables in UPS Battery Sizing

The following parameters must be determined before any UPS battery sizing:

| Variable | Description | Common Values / Ranges (per IEEE & IEC) |

|---|---|---|

| P_load | Total load power (Watts or kW) | 500 W – 500 kW for commercial UPS |

| V_dc | DC bus voltage of UPS | 48 V, 110 V, 192 V, 240 V, 384 V, 480 V |

| t_aut | Required autonomy time | 5, 10, 15, 30, 60, 120 min |

| η_inv | UPS inverter efficiency | 0.90 – 0.97 |

| DOD_max | Maximum allowable Depth of Discharge | 0.80 for VRLA, 0.70 for flooded |

| Temp_C | Ambient temperature | 20°C – 30°C (nominal) |

| CF_temp | Temperature correction factor | 1.00 @ 25°C, up to 1.30 @ 0°C |

| CF_age | Aging factor | 1.25 (typical for 5–10 year life) |

| E_cell | Nominal cell voltage | 2.0 V per cell (lead-acid) |

| K_peuk | Peukert’s exponent | 1.10 – 1.30 (battery type dependent) |

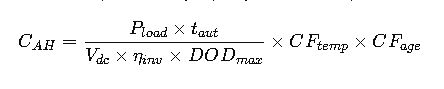

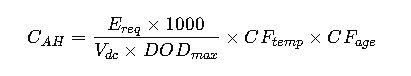

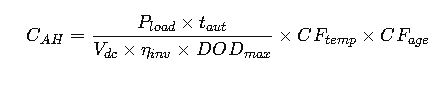

Main UPS Battery Sizing Formula (IEEE 485)

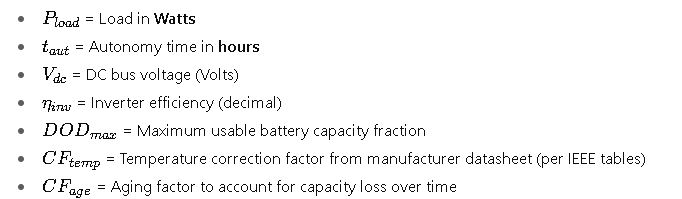

The standard approach to calculate required battery capacity (C_AH) in ampere-hours:

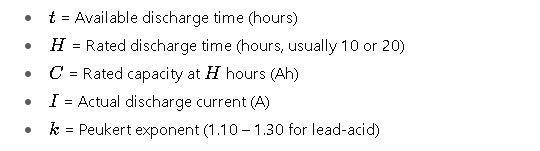

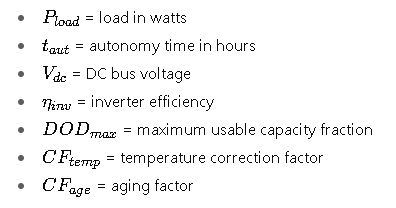

Where:

Example Temperature Correction Factors (IEEE/IEC)

| Temperature (°C) | CF_temp (VRLA) | CF_temp (Flooded) |

|---|---|---|

| 25 | 1.00 | 1.00 |

| 20 | 1.04 | 1.03 |

| 10 | 1.11 | 1.09 |

| 0 | 1.30 | 1.25 |

Extended Table of Common UPS Battery Sizing Scenarios

Below is a reference table for typical configurations.

Assumes VRLA battery, η_inv = 0.94, DOD_max = 0.8, CF_age = 1.25, CF_temp = 1.00.

| P_load (kW) | V_dc (V) | t_aut (min) | Required C_AH |

|---|---|---|---|

| 5 | 240 | 10 | 16.7 AH |

| 5 | 240 | 30 | 50.0 AH |

| 5 | 240 | 60 | 100.0 AH |

| 10 | 240 | 10 | 33.4 AH |

| 10 | 240 | 30 | 100.0 AH |

| 10 | 240 | 60 | 200.0 AH |

| 20 | 384 | 15 | 81.4 AH |

| 20 | 384 | 30 | 162.8 AH |

| 20 | 384 | 60 | 325.6 AH |

| 50 | 480 | 15 | 163.0 AH |

| 50 | 480 | 30 | 326.0 AH |

| 50 | 480 | 60 | 652.0 AH |

Advanced IEEE & IEC UPS Battery Sizing Formulas

While the main IEEE 485 formula is widely used, additional corrections and methods are necessary for precise UPS battery sizing under non-standard conditions such as high discharge rates, extreme temperatures, and variable load profiles.

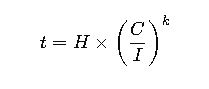

1. Peukert’s Law (High-Rate Discharge Adjustment)

Purpose:

To account for the fact that available battery capacity decreases as discharge current increases.

Formula:

Where:

In UPS applications, I can be 2–10 times higher than nominal rating for short autonomy times, which can significantly reduce available capacity.

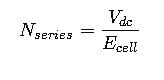

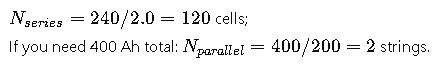

2. Battery String Voltage Calculation

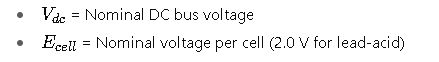

Number of Cells in Series (N_series):

Where:

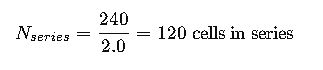

Example:

For a 240 V DC bus with lead-acid cells:

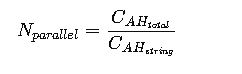

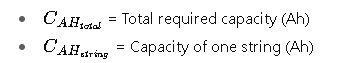

3. Number of Parallel Strings

If one battery string cannot supply the total required capacity, additional parallel strings are added:

Where:

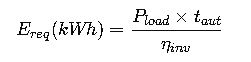

4. Energy-Based Sizing (kWh Method)

Sometimes, energy in kWh is used rather than Ah for quick estimation:

Then:

This is essentially the same as the main formula but emphasizes the energy dimension.

5. IEC Correction for End-of-Discharge Voltage (EODV)

IEC 60896 specifies that usable capacity depends on the end voltage per cell during discharge:

- For UPS: EODV = 1.75 V/cell (VRLA) or 1.80 V/cell (Flooded)

- Lower EODV allows more energy extraction but reduces cycle life.

Manufacturers’ discharge tables (Ah vs. time vs. EODV) should be used to refine the sizing.

Common Reference Values from IEEE/IEC Guidelines

| Parameter | VRLA Typical | Flooded Typical | Notes |

|---|---|---|---|

| Nominal Cell Voltage | 2.0 V | 2.0 V | Lead-acid chemistry |

| Float Voltage @ 25°C | 2.25–2.30 V/cell | 2.20–2.25 V/cell | Per cell |

| EODV (UPS duty) | 1.75 V/cell | 1.80 V/cell | Short discharge |

| Peukert Exponent | 1.12–1.18 | 1.18–1.25 | Lower is better |

| DOD_max | 80% | 70% | To prolong life |

| Life Expectancy | 5–10 years | 10–20 years | Nominal, @ 25°C |

| Temp Correction Start | 25°C | 25°C | Reference temperature |

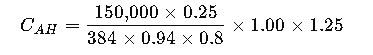

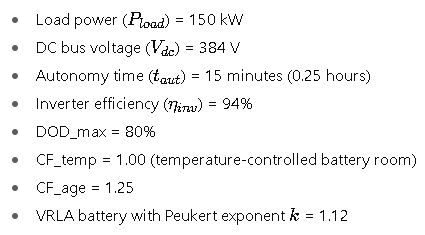

Real-World Case Study #1 – Data Center UPS Battery Sizing

Scenario:

A Tier III data center requires a UPS to support critical IT load during outages until generators start. The specifications are:

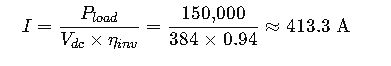

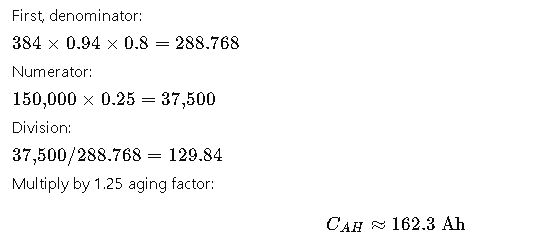

Step 1: Calculate Required Ah Without Peukert Adjustment

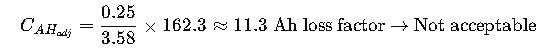

Step 2: Apply Peukert Adjustment

UPS discharges in 15 min are high rate → capacity loss:

Rated capacity time H=10 hours

Rated capacity C=162.3 Ah

Discharge current:

Available time using Peukert:

Raise to 1.12: ≈ 0.358

Multiply by 10: ≈ 3.58 hours equivalent → capacity must be scaled for 0.25 h:

In practice: select next higher battery capacity from manufacturer tables (e.g., 200 Ah VRLA).

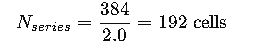

Step 3: Determine Battery Configuration

Nominal cell voltage = 2.0 V

Number of cells in series:

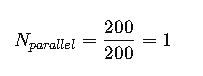

If each cell is 200 Ah:

Required strings in parallel:

Final selection: 192 cells of 200 Ah VRLA in one series string.

Frequently Asked Questions (FAQ) – UPS Battery Sizing Calculator (IEEE & IEC)

1. What is the main IEEE standard for UPS battery sizing?

The primary reference is IEEE Std 485 – IEEE Recommended Practice for Sizing Lead-Acid Batteries for Stationary Applications.

It outlines step-by-step methods, derating factors, and environmental considerations for sizing VRLA and flooded lead-acid batteries in UPS systems.

IEC 60896 provides complementary requirements for stationary lead-acid batteries, especially regarding testing and performance.

2. How do I calculate UPS battery capacity in ampere-hours (Ah)?

Use the IEEE 485 formula:

Where:

3. What is the role of Peukert’s Law in UPS battery sizing?

Peukert’s Law adjusts for the reduced capacity of batteries under high-rate discharge.

In UPS systems, short autonomy times mean high discharge currents, so Peukert’s exponent is applied to avoid undersizing.

Ignoring it can lead to batteries failing to meet required backup time.

4. How many batteries do I need in series and parallel?

- Series: Divide the DC bus voltage by nominal cell voltage (2.0 V for lead-acid).

- Parallel: Divide the total required Ah by the Ah of one string.

Example: For a 240 V DC bus with 200 Ah cells,

5. What is the maximum Depth of Discharge (DOD) for UPS batteries?

- VRLA: typically 80%

- Flooded: typically 70%

Exceeding these values regularly shortens battery life significantly.

6. How does temperature affect UPS battery capacity?

Battery capacity decreases at low temperatures and increases slightly at higher temperatures.

IEEE provides CF_temp correction factors, e.g., at 0°C VRLA batteries may require 30% more capacity to meet the same load.

7. What is the recommended aging factor (CF_age)?

Common practice:

- Short life (3–5 years): CF_age ≈ 1.10

- Medium life (5–10 years): CF_age ≈ 1.25

- Long life (10–20 years): CF_age ≈ 1.30

This accounts for capacity degradation over the battery’s service life.

8. Can I use lithium-ion batteries for UPS instead of lead-acid?

Yes, but IEEE 485 and IEC 60896 are primarily for lead-acid.

Lithium-ion batteries require manufacturer-specific sizing methods, thermal management considerations, and different end-of-discharge voltage criteria.

However, they offer higher cycle life, lighter weight, and better high-rate performance.

9. What’s the difference between IEEE and IEC approaches?

- IEEE: Focuses on sizing methodology, correction factors, and recommended practices (North American origin).

- IEC: Focuses on battery performance testing, design requirements, and international standardization (European origin).

For best results, both should be consulted together.

10. How often should I recheck my UPS battery sizing?

Whenever:

- Load changes by more than 10%

- Autonomy requirements change

- Environmental conditions change significantly

In critical facilities, review at least every 2–3 years.