Explore the precise calculation of grouping correction factors in cables. Understand cable performance adjustments through organized, efficient grouping methodologies today.

Calculate grouping correction factors accurately using detailed formulas, practical examples, and guidelines for safe, efficient cable installations in complex systems.

AI-powered calculator for Grouping Correction Factor Calculation in Cables

Example Prompts

- 4 cables, spacing 30 mm, installation depth 150 mm

- 6 cables, spacing 50 mm, ambient temperature 35°C

- 8 cables, spacing 40 mm, cable diameter 25 mm

- 10 cables, spacing 60 mm, conduit length 2000 mm

Understanding Grouping Correction Factor in Cables

Grouping correction factors in cables are essential adjustments applied to current-carrying capacities when multiple cables are bundled together. As cables grouped closely affect mutual heating and dissipation of heat, these factors ensure that the installation remains within safe operating conditions. Understanding this calculation is crucial for accurate design and compliance with electrical standards.

Electrical installations often require cables to be installed in groups, either within cable trays, conduits, or ducts. In such cases, the total amount of heat generated by the cables can be higher than that produced by a single cable installed independently. The grouping correction factor, sometimes referred to as the “binning factor” or “derating factor,” is a multiplier applied to adjust the estimated thermal load. This adjustment guarantees that the cables are not overburdened by excessive current, ensuring both longevity and safety.

Fundamental Principles Behind Grouping Correction Factors

Several factors influence the grouping correction factor, such as the number of cables, cable spacing, installation environment, and ambient temperature. Codes and industry standards, including those from the International Electrotechnical Commission (IEC) and the National Electrical Code (NEC), provide detailed guidelines on corrections.

The inherent concept behind grouping correction factors revolves around the heat dissipation capabilities of cables. When cables are placed in close proximity, the heat generated by each cable interferes with the cooling of its neighbors, necessitating a reduction in the permissible current-carrying capacity. Hence, designers and engineers apply grouping correction factors as a safety measure.

Fundamental Formulas for Grouping Correction Factor Calculation in Cables

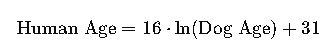

The calculation can often be simplified by the following formula:

In this formula, each variable represents:

- N: The number of cables placed together (group size).

- F: A correction coefficient that depends on cable spacing, installation conditions, and ambient temperature.

An alternative, more detailed formula sometimes used in engineering practice is:

Where:

- T_b: Base temperature rise permitted for individual cables.

- T_a: Actual temperature rise observed when cables are grouped.

- A_c: Cross-sectional area of the cables.

- A_e: Effective additional area accounting for cable proximity and installation environment.

Each formula variant has its specific application context, and engineers must choose the one that fits the specific installation scenario while adhering to regional code requirements.

In-depth Explanation of Variables and Their Implications

Understanding each term in the correction factor formulas is vital:

- N (Number of Cables): Increasing the count from 1 will typically decrease the capacity as mutual heating increases.

- F (Correction Coefficient): This factor is determined by empirical studies, installation layout, cable spacing, conduit or tray dimensions, and ambient temperature. Engineers typically use standardized tables or simulation software to determine F.

- T_b vs. T_a: The ratio of base temperature rise to actual temperature rise indicates how far the installation deviates from ideal cooling conditions.

- A_c vs. A_e: A larger cable cross-section usually leads to improved heat transfer, whereas a smaller effective additional area indicates a denser setup, requiring a tougher derating factor.

Both formulas reflect the balance between heat generation and dissipation. In practice, thorough consideration of these variables results in safer cable designs and enhanced longevity of electrical installations.

Extensive Tables for Grouping Correction Factor Calculation

Below is an extensive table outlining example grouping correction factors for various numbers of cables and typical installation conditions. These values are approximate and should be validated against local codes.

| Number of Cables (N) | Spacing (mm) | Ambient Temperature (°C) | Grouping Correction Factor |

|---|---|---|---|

| 1 | – | 25 | 1.00 |

| 3 | 30 | 30 | 0.85 |

| 5 | 50 | 35 | 0.78 |

| 8 | 40 | 40 | 0.70 |

| 10 | 60 | 45 | 0.65 |

This table is a guide that illustrates how grouping correction factors vary with installation specifics. Engineers often refer to manufacturer data and code-specific tables for the most precise values.

Methodology for Grouping Correction Factor Calculation

The step-by-step process below outlines a standard methodology to compute the grouping correction factor in cable assemblies. This method emphasizes practicality and adherence to safety standards.

- Step 1: Determine the Number of Cables (N) – Count the number of cables that will be grouped together within the same cable tray or conduit.

- Step 2: Identify Installation Conditions – Note the spacing between cables (in mm), ambient temperature, and installation environment. Obtain the correction coefficient F from standard reference tables.

- Step 3: Apply the Basic Formula – Use the simplified formula: Grouping Correction Factor = 1 / (1 + (N – 1) × F). Substitute the appropriate values for each variable.

- Step 4: Validate Against Detailed Models – Where necessary, apply the alternative formula with temperature and area factors for greater precision.

- Step 5: Documentation and Review – Record all parameters, calculations, and any assumptions made during the process to facilitate review and audits.

This method ensures a structured approach and reduces errors, thereby protecting the system’s integrity. Detailed planning here is critical, especially in environments with strict safety requirements.

Real-Life Application Case #1: Cable Tray Grouping in an Industrial Installation

In an industrial plant, several power cables are installed in a cable tray that runs across a production floor. The cable grouping causes a higher ambient temperature in the tray due to heat accumulation.

Assume seven identical cables are grouped in a tray with 40 mm spacing. The ambient temperature is 35°C, and the standard lookup value for F in similar conditions is 0.10. Using the simplified formula: Grouping Correction Factor = 1 / (1 + (N – 1) × F), substitute the values:

Calculate the intermediate value:

Thus, the grouping correction factor becomes:

Engineers then adjust the nominal current rating of the cables accordingly. For instance, if each cable is rated for 150 A under free-air conditions, the effective current-carrying capacity in the grouped scenario becomes 150 A × 0.625 = 93.75 A per cable. This derated capacity is critical for ensuring that the cable tray does not overheat during prolonged operation.

Real-Life Application Case #2: Conduit Grouping in a Commercial Building

Consider a commercial building installation where a bundle of eight cables is run through a conduit with limited ventilation in a high-rise structure. The cables are tightly bundled with a spacing of 35 mm, and the measured ambient temperature is 40°C. An empirical data table suggests using F = 0.12 in these conditions.

Using the basic formula:

Compute the expression:

Thus, the adjusted grouping correction factor is:

For cables originally capable of carrying 200 A, application of the correction factor provides an effective current rating of 200 A × 0.543 = 108.6 A per cable. This helps ensure the installation remains within safe limits despite the high ambient conditions and connector proximity.

Additional Practical Considerations in Grouping Correction Factor Calculation

Beyond the primary calculation, various practical factors can impact the grouping correction factor. These include cable construction, insulation type, installation configuration, and even the presence of adjacent heat sources.

- Cable Conductor Material: Copper and aluminum cables have different thermal characteristics. Copper’s higher conductivity might allow for slightly higher current ratings despite grouping.

- Insulation Type: The thermal resistance of cable insulation influences heat transfer. High-temperature insulation materials require adjusted derating factors.

- Installation Environment: Indoor versus outdoor installations, the presence of ventilation systems, and ambient temperature variations all affect the final grouping correction factor.

- Regulatory Requirements: Many local and international codes specify mandatory derating factors to address safety margins under varying conditions.

Understanding these considerations is key to ensuring a robust and safe cable installation. In many scenarios, a conservative approach is recommended, particularly in critical power systems.

Advanced Techniques and Software Applications

Modern electrical engineering increasingly relies on software tools to simulate cable installations. These software applications compute grouping correction factors by inputting numerous parameters and environmental data.

Popular software tools include ETAP, SKM Power Tools, and CableSizer. These applications allow engineers to simulate heat dissipation, current load, and dynamic environmental changes, providing a detailed overview of the cable installation’s performance. Their advanced algorithms account for not only the basic formulas but also complex interactions between cables, installation geometry, and external conditions. Using these tools helps engineers optimize cable layouts, improve energy efficiency, and ensure compliance with international standards.

- Simulation Capabilities: In-depth simulation models consider transient thermal conditions, enabling dynamic derating analysis beyond static factors.

- Customizable Parameters: Engineers can alter parameters such as cable spacing, ambient temperature variations, and wall conductivities within the simulation to explore various scenarios.

- Improved Accuracy: Using real-time data and simulation feedback leads to more precise grouping correction factor determinations.

These advanced techniques enhance the understanding of cable behavior in complex environments, pushing the boundaries of conventional calculations.

Comparative Analysis: Standard Versus Optimized Cable Grouping

A comparative analysis provides valuable insights for engineers deciding between standard and optimized cable grouping scenarios.

Consider two cases: Case A involves standard cable grouping with minimal spacing and typical ambient conditions, while Case B establishes an optimized layout with increased spacing and enhanced ventilation. Although the standard grouping may yield a correction factor of around 0.65, the optimized configuration could improve the factor to 0.80 or higher. This improvement not only increases the effective current-carrying capacity but also enhances safety margins, reduces cable aging, and minimizes fire hazards.

Below is a table comparing key parameters and outcomes between the two cases:

| Criterion | Standard Grouping | Optimized Grouping |

|---|---|---|

| Cable Spacing | 30-40 mm | 50-60 mm |

| Ambient Temperature | 30-35°C | 25-30°C |

| Grouping Correction Factor | 0.65-0.70 | 0.80-0.85 |

| Installation Cost | Lower | Slightly Higher |

| System Reliability | Moderate | Enhanced |

This comparative analysis illustrates how design choices impact both performance and safety. While optimized grouping might incur increased upfront costs, the long-term benefits in reliability and energy efficiency are often well worth the investment.

Integrating Grouping Correction Factor Calculations with Regulatory Standards

Electrical regulations worldwide emphasize accurate current capacity calculations to prevent hazardous conditions. The grouping correction factor is an integral part of these calculations, ensuring that grouped cables meet stringent safety requirements.

In Europe, the IEC standards provide explicit formulas and tabulated correction factors for different installation scenarios. Similarly, in the United States, the NEC specifies derating factors in its installation guidelines. Both sets of regulations mandate regular recalculations and validation through periodic inspections. Engineers must always ensure their calculations align with the latest regulatory updates and independent testing results, thereby fostering a culture of safety and compliance.

Industry Best Practices and Recommendations

To achieve optimal results in grouping correction factor calculations, adhere to these industry best practices:

- Regularly Update Data: Use the most current tables and codes provided by recognized bodies such as IEC and NEC.

- Perform Detailed Site Surveys: Empirical measurements of ambient temperature, cable spacing, and installation conditions yield more accurate corrections.

- Use Simulation Software: Validate manual calculations with advanced simulation tools to verify assumptions and results.

- Plan for Future Scalability: Factor in anticipated changes in cable arrangement and environmental conditions when designing systems.

- Maintain Thorough Documentation: Accurate records of assumptions, methodologies, and calculations help during audits and troubleshooting.

These recommendations represent the pinnacle of good engineering practices. Integrating them into daily workflows minimizes errors and enhances the overall safety and efficiency of electrical installations.

External Resources and Further Reading

For additional information on cable grouping and current deratings, refer to authoritative sources. The International Electrotechnical Commission (IEC) offers comprehensive documentation on cable installation standards. Visit the official IEC website at IEC.

The National Fire Protection Association (NFPA) provides extensive guidance on cable installation and safety measures in the National Electrical Code. More detailed discussions can also be found on online platforms such as ETAP and technical blogs by seasoned electrical engineers. Leveraging these resources can further clarify complex topics related to grouping correction factors.

Frequently Asked Questions

Below are answers to some of the most common questions regarding grouping correction factor calculations:

-

Q: What is the grouping correction factor?

A: It is a multiplier that adjusts the current-carrying capacity of cables when grouped together, accounting for mutual heating effects. -

Q: How is the correction factor calculated?

A: It is typically calculated using the formula 1 / (1 + (N – 1) × F) where N is the number of cables and F is a correction coefficient derived from installation conditions. -

Q: Which variables affect the grouping correction factor?

A: Variables include the number of cables, cable spacing, ambient temperature, insulation type, and installation environment. -

Q: Can the grouping correction factor be optimized?

A: Yes, by increasing cable spacing and improving ventilation in installations, the effective derating factor can be improved, leading to a higher current capacity.

These FAQs address typical concerns and provide a basic understanding of grouping correction factor concepts and their practical implications.

Integrating Experienced Engineering Judgment with Calculation Tools

While mathematical formulas and simulation software are invaluable, the experienced judgment of a seasoned electrical engineer remains irreplaceable. Practical scenarios often involve unforeseen circumstances and environmental nuances that basic calculations may not capture.

For example, an installation in an industrial setting might involve additional heat sources or unique cable arrangements that slightly deviate from standard tabulated data. In these situations, an engineer’s judgment helps adjust the grouping correction factor using conservative estimates and safety margins. Combining best practices, accurate simulations, and on-site assessments ensures robust, reliable outcomes that uphold safety and performance.

The Role of Grouping Correction Factor Calculations in Energy Efficiency

Accurate grouping correction factor calculations do not merely enhance safety; they also contribute significantly to energy efficiency. By precisely predicting cable performance under grouped conditions, designers can optimize cables to operate closer to their rated capacities without unnecessary conservatism.

This optimization leads to several benefits:

- Reduced Energy Loss: Efficient cable grouping minimizes excessive energy loss due to overheating and inefficient cooling.

- Cost Savings: Optimized cable ratings reduce the need for oversized conductors, resulting in lower material and installation costs.

- Improved System Reliability: Correctly derated cables operate within safer temperature ranges, reducing the risk of thermal degradation and failure.

- Environmental Impact: Energy efficiency translates into a lower carbon footprint, aligning with global sustainability goals.

Therefore, proper calculation and application of grouping correction factors play a fundamental role in designing energy-efficient, cost-effective electric systems.

Future Trends in Cable Grouping and Correction Factors

The field of cable installation is evolving, and so are the methods for calculating grouping correction factors. Future trends include the integration of IoT sensors for real-time monitoring of cable temperatures and automated adjustment of derating factors.

Smart cable management systems that continuously monitor ambient conditions and cable temperatures can inform dynamic adjustments to current ratings, thus increasing the resilience and adaptability of modern electrical grids. Research into advanced materials with improved thermal properties may also lead to higher grouping correction factors, reducing the need for severe derating. These trends promise to further enhance safety, energy efficiency, and the longevity of electrical installations.

Practical Checklist for Engineers

To ensure consistent application of grouping correction factor calculations, engineers can utilize the following practical checklist during installations:

- Confirm the exact number of cables grouped in the tray or conduit.

- Measure cable spacing accurately and review any manufacturer-provided guidelines.

- Assess ambient and operational temperatures through site surveys or simulation data.

- Determine the appropriate correction coefficient (F) from trusted tables or software tools.

- Apply the chosen formula and document every step for future reference.

- Reassess the design if installation conditions change or new regulations are issued.

- Validate calculations through peer-review and cross-checking with simulation outputs.

Using this checklist ensures a rigorous and methodical approach, ultimately resulting in safer and more efficient cable system designs.

Conclusion: Embracing Precision and Innovation in Cable Grouping

Grouping correction factor calculation is a nuanced subject, weaving together empirical data, standardized formulas, and advanced engineering judgment. Each installation presents unique challenges, from industrial plants to commercial buildings, necessitating careful analysis of heat dissipation and cable interactions.

The methods and examples presented here provide a comprehensive guide to understanding, calculating, and optimizing grouping correction factors in cables. Embracing both tried-and-true engineering principles and innovative simulation tools, professionals can ensure that every installation meets rigorous safety standards while achieving optimal efficiency.

By continuously refining calculation methods and integrating emerging technologies, the electrical engineering community stands poised to tackle complex challenges in cable installations. The precision and innovation demonstrated in these techniques are a testament to the ongoing evolution of safe, reliable, and efficient electrical systems worldwide.

For more detailed insights and technical support on grouping correction factor calculations, engineers are encouraged to consult updated industry standards, collaborate with peers, and utilize cutting-edge simulation tools. The future of electrical installations lies in harnessing both human expertise and technological innovation.