Impact force is a critical concept in physics and engineering, essential for safety and structural integrity. Calculating and interpreting impact forces enables designing safer systems, preventing injuries, and applying practical engineering solutions.

Impact Force Calculator (F)

Which formula is used?

F = 2·m·h / t² for free-fall drop calculation.

Recommended units

Common Values of Impact Force

| Scenario | Mass (kg) | Velocity (m/s) | Impact Distance (m) | Impact Force (N) |

|---|---|---|---|---|

| Falling person (1.2 m height) | 90 | 4.9 | 0.02 | 53,000 |

| Car crash (15 m/s, 0.5 m crumple) | 1,500 | 15 | 0.5 | 450,000 |

| Bungee jumper (70 kg, 50 m drop) | 70 | 31.3 | 10 | 2,190 |

| Baseball bat impact (0.145 kg, 40 m/s) | 0.145 | 40 | 0.01 | 232,000 |

| Human landing (parkour, 2 m fall) | 75 | 6.26 | 0.05 | 90,000 |

Note: These values are approximations for illustrative purposes.

Fundamental Formulas for Impact Force Calculation

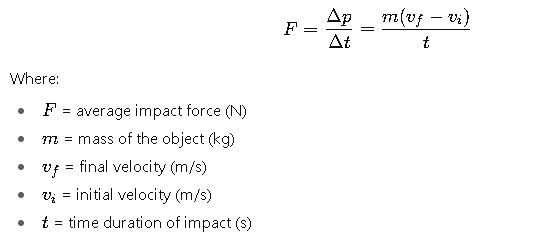

1.Impulse-Momentum Theorem: This principle states that the change in momentum (Δp) of an object is equal to the impulse (FΔt) applied to it. Mathematically,

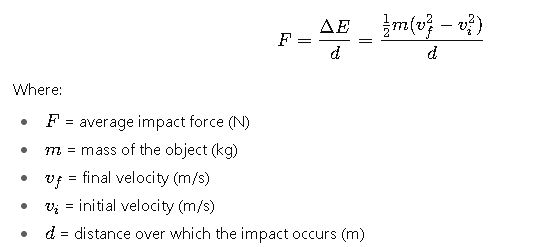

2.Work-Energy Principle: This approach relates the work done (force applied over a distance) to the change in kinetic energy. The formula is:

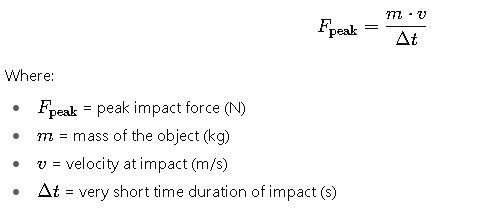

3.Peak Impact Force: In cases of very short impact durations, the peak force can be significantly higher than the average force. An estimation is given by:

Real-World Examples of Impact Force Calculations

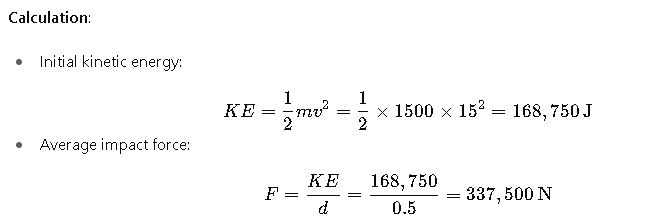

1. Car Collision

Scenario: A car with a mass of 1,500 kg crashes into a wall at 15 m/s. The crumple zone of the car compresses by 0.5 meters before coming to a stop.

Interpretation: The car experiences a substantial force during the collision, highlighting the importance of crumple zones in reducing impact forces and protecting occupants.

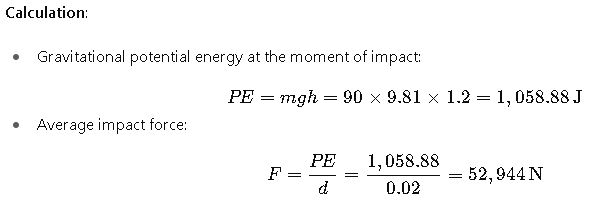

2. Human Fall

Scenario: A person weighing 90 kg falls from a height of 1.2 meters onto a surface that compresses 2 cm during the impact.

Interpretation: The person experiences a significant force upon landing, emphasizing the need for protective gear and proper landing techniques to mitigate injury risks.

Strategies to Reduce Impact Forces

- Increase Impact Duration: By extending the time over which the impact occurs, the average force experienced can be reduced. This principle is utilized in safety features like airbags and crumple zones in vehicles.

- Use of Energy-Absorbing Materials: Materials such as foams and gels can absorb energy during an impact, thereby reducing the force transmitted to the object or person.

- Proper Design of Safety Gear: Helmets, pads, and other protective equipment are designed to spread out the impact force over a larger area and increase the duration of the impact, thereby reducing the peak force experienced.

Understanding the Dynamics of Impact

Impact force arises when two bodies collide, resulting in a rapid exchange of momentum and energy. The magnitude of this force depends on several factors, including the mass of the objects, their velocities, the duration of contact, and the deformation characteristics of the surfaces involved. Unlike static forces, impact forces are highly dynamic and can vary significantly within milliseconds of the collision.

Key Variables Affecting Impact Force:

- Mass: Heavier objects naturally produce higher forces upon impact. For example, a falling 100 kg object exerts a far greater force than a 10 kg object from the same height.

- Velocity: The speed at which the object strikes dramatically affects the force. Doubling the velocity nearly quadruples the kinetic energy, increasing the potential impact force.

- Contact Duration: Longer contact times during impact allow energy to dissipate gradually, reducing peak forces. This principle underlies the design of cushioning materials, crumple zones in cars, and sports protective gear.

- Surface Deformation: Softer or deformable surfaces absorb energy, reducing the effective force transmitted. Rigid surfaces, conversely, increase the peak impact force and the risk of damage or injury.

Real-World Applications of Impact Force Calculation

Automotive Safety

Automotive engineers use impact force calculations to design safer vehicles. Crumple zones, airbags, and seatbelts are engineered to manage the energy during collisions, reducing the peak forces experienced by passengers. Detailed simulations are conducted to estimate forces in various collision scenarios, including frontal, side, and rear impacts.

Example: In a frontal crash at 50 km/h, the car’s crumple zone absorbs the majority of kinetic energy over 0.5–1 meter of deformation. Airbags then distribute remaining forces across the passenger’s torso and head, preventing injuries that would occur if the impact were concentrated on a small area.

Sports Engineering

In sports like football, hockey, and gymnastics, impact force calculations inform helmet design, padding, and floor materials. Helmets are not just rigid shells; they include multiple layers of energy-absorbing materials to dissipate forces from collisions or falls. Gymnastics mats are designed to deform under load, extending the contact time and reducing injury risk.

Common Ranges of Impact Forces in Everyday Scenarios

| Scenario | Typical Mass | Typical Velocity | Estimated Impact Force |

|---|---|---|---|

| Baseball hitting bat | 0.145 kg | 40 m/s | 200,000–250,000 N |

| Car crash at 50 km/h | 1,500 kg | 13.9 m/s | 300,000–400,000 N |

| Human landing from 2 m fall | 75 kg | 6.3 m/s | 90,000–100,000 N |

| Hammer striking nail | 2 kg | 8 m/s | 600–800 N |

| Industrial machinery impact | 500 kg | 2 m/s | 2,000–3,000 N |

This table shows the dramatic range of forces depending on mass, velocity, and impact context. Understanding these forces helps engineers design safer systems, from personal protective equipment to large-scale industrial machines.

Materials and Impact Force Mitigation

Materials play a critical role in controlling impact forces. Engineers select materials based on their energy absorption capacity, stiffness, and deformation characteristics:

- Foams and Elastomers: These materials compress under load, increasing the time over which impact occurs and reducing peak forces.

- Metals with High Ductility: Structural components in vehicles often use high-ductility steel that can deform without fracturing, absorbing energy during collisions.

- Composite Materials: Carbon fiber composites in aerospace and automotive applications combine stiffness and controlled energy dissipation.

Advanced Considerations

- Multi-Stage Impacts: Many collisions involve multiple contacts, like a falling object bouncing off surfaces. Each impact has a distinct force profile that must be calculated separately.

- Angular Impacts: Impacts rarely occur perfectly perpendicular. Oblique collisions introduce shear forces and torsion, which can drastically change the force distribution.

- Dynamic vs. Static Calculations: Unlike static load analysis, impact force calculation must consider time-dependent changes in momentum and energy, often requiring simulation tools like finite element analysis (FEA) for precision.

Standards and Guidelines

Calculating impact force often follows standardized approaches to ensure safety and consistency:

- ISO 8124 – Safety of Toys: Specifies test conditions for toy impacts to prevent injuries.

- ECE R94 and R95 – Vehicle crash regulations: Define how to measure forces in frontal and side collisions.

- ASTM D3763 – Standard Test Method for High-Speed Puncture Resistance of Plastics: Relevant for material testing in impact scenarios.

Using these guidelines ensures calculations are not just theoretical but applicable and compliant with legal and safety requirements.