The Star-Delta Motor Starter is widely used, standardized, and preferred for three-phase induction motors worldwide. According to IEEE standards, star-delta starting suits squirrel-cage motors above 5 HP, preventing voltage dips.

Star–Delta Motor Starter Calculator — IEEE style

Estimate full-load current, starting current (DOL), and reduced starting current when using Star (Y) start. Designed for 3-phase motors.

Extensive Reference Tables for Star-Delta Motor Starter Calculator – IEEE

The following tables summarize common parameters used in star-delta calculations, including power ratings, line voltages, full-load currents, starting current multipliers, and starter configurations.

Table 1: Motor Power Ratings and Corresponding Line Currents (50 Hz, 400 V, 3-Phase)

| Motor Power (kW) | Motor Power (HP) | Line Current (A) | Starting Current (DOL, A) | Starting Current (Star-Delta, A) |

|---|---|---|---|---|

| 5.5 kW | 7.5 HP | 10 A | 60 A | 20 A |

| 7.5 kW | 10 HP | 14 A | 84 A | 28 A |

| 11 kW | 15 HP | 21 A | 126 A | 42 A |

| 15 kW | 20 HP | 28 A | 168 A | 56 A |

| 18.5 kW | 25 HP | 35 A | 210 A | 70 A |

| 22 kW | 30 HP | 42 A | 252 A | 84 A |

| 30 kW | 40 HP | 58 A | 348 A | 116 A |

| 37 kW | 50 HP | 70 A | 420 A | 140 A |

| 45 kW | 60 HP | 85 A | 510 A | 170 A |

| 55 kW | 75 HP | 105 A | 630 A | 210 A |

| 75 kW | 100 HP | 142 A | 852 A | 284 A |

| 90 kW | 120 HP | 170 A | 1020 A | 340 A |

| 110 kW | 150 HP | 210 A | 1260 A | 420 A |

| 132 kW | 175 HP | 255 A | 1530 A | 510 A |

| 160 kW | 215 HP | 310 A | 1860 A | 620 A |

| 200 kW | 270 HP | 390 A | 2340 A | 780 A |

Table 2: Typical Star-Delta Starter Settings by Motor Size

| Motor Power (kW) | Recommended Starter Size (kW) | Contactor Rating (A) | Timer Delay (s) | Overload Relay (A) |

|---|---|---|---|---|

| 5.5 – 7.5 kW | 10 kW | 32 A | 6 – 8 s | 10 – 14 A |

| 11 – 15 kW | 20 kW | 50 A | 7 – 10 s | 20 – 25 A |

| 18.5 – 22 kW | 30 kW | 63 A | 8 – 12 s | 28 – 35 A |

| 30 – 37 kW | 50 kW | 100 A | 10 – 15 s | 40 – 55 A |

| 45 – 55 kW | 75 kW | 150 A | 12 – 18 s | 60 – 75 A |

| 75 – 90 kW | 125 kW | 225 A | 15 – 20 s | 100 – 130 A |

| 110 – 132 kW | 200 kW | 315 A | 18 – 25 s | 150 – 220 A |

| 160 – 200 kW | 315 kW | 400 – 500 A | 20 – 30 s | 250 – 380 A |

Table 3: Voltage, Current, and Torque Ratios in Star-Delta Starting

| Parameter | Direct-on-Line (DOL) | Star Connection | Delta Connection |

|---|---|---|---|

| Line Voltage | VL | VL / √3 | VL |

| Phase Voltage | VL | VL / √3 | VL |

| Line Current | IL | IL / √3 | IL |

| Starting Current | 100% (base) | 33% of DOL | 100% (full load) |

| Starting Torque | 100% (base) | 33% of DOL | 100% (full load) |

| Power Factor | 0.8 – 0.9 | Slightly lower | Standard value |

Core Formulas for Star-Delta Motor Starter Calculator – IEEE

The star-delta method is based on the transformation of winding connection from star (Y) during starting to delta (Δ) during running. Below are the key formulas:

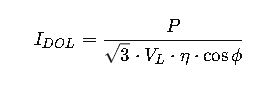

1. Line Current (DOL)

- P = motor power (W)

- VL = line voltage (V)

- η = efficiency (decimal)

- cosφ = power factor

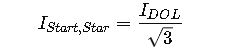

2. Starting Current (Star Connection)

This reduction is due to the phase voltage being VL/√3 in star connection.

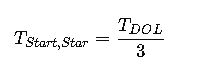

3. Starting Torque

Where:

- TStart,Star = torque during star starting

- TDOL = torque at direct-on-line

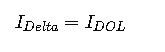

4. Current in Delta (Running Condition)

In delta, the motor achieves its rated torque and rated current.

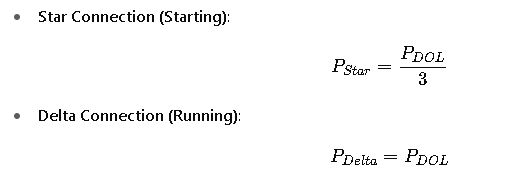

5. Power in Star and Delta

6. Example of Contactors Sizing

IEEE recommends:

- Main Contactor (KM1): Rated for 58% of full-load current.

- Delta Contactor (KM2): Rated for 58% of full-load current.

- Star Contactor (KM3): Rated for 33% of full-load current.

Common Variable Ranges

- Efficiency (η): 0.85 – 0.96 (industrial motors)

- Power factor (cosφ): 0.80 – 0.92

- Timer delay: 6 – 30 seconds (depends on motor inertia and load type)

- Starting torque: Typically 1/3 of DOL torque

Real-World Application Examples of Star-Delta Motor Starter Calculator – IEEE

To fully understand how the Star-Delta Motor Starter Calculator is applied, let’s analyze real industrial cases. These examples highlight how engineers use IEEE methodologies to size equipment, predict performance, and ensure compliance with safety and efficiency standards.

Case Study 1: 30 kW Pump Motor in a Water Treatment Plant

Scenario

A municipal water treatment facility uses a 30 kW, 400 V, 3-phase induction motor to drive a centrifugal pump. Direct-on-line starting caused repeated voltage dips affecting nearby sensitive instrumentation. Engineers opted for a star-delta starter to reduce inrush current.

Step-by-Step Approach

- Motor Full-Load Current

According to standard tables (see earlier), a 30 kW motor at 400 V has a full-load current of 58 A. - DOL Starting Current

Typical starting current is 6 × full-load current, which equals about 348 A. - Star-Delta Starting Current

With star-delta, current reduces to roughly 1/3 of DOL, giving 116 A. - Torque Impact

Starting torque is also reduced to 1/3 of the DOL torque, but since the pump is a low-inertia load, reduced torque is acceptable. - Starter Settings

- Contactor Rating: 100 A

- Timer Delay: 10–12 seconds

- Overload Relay: 40–55 A range

Result

The plant achieved stable pump operation without voltage dips. Power quality in the local distribution improved significantly, and the motor protection system aligned with IEEE standards for safety and longevity.

Case Study 2: 90 kW Conveyor Motor in a Cement Plant

Scenario

A 90 kW induction motor powers a long conveyor belt transporting raw materials in a cement factory. Direct-on-line starting caused mechanical stress on the belt system and tripped upstream circuit breakers.

Step-by-Step Approach

- Motor Full-Load Current

From reference tables, a 90 kW motor at 400 V has a full-load current of 170 A. - DOL Starting Current

Approximate surge current is 1,020 A. This level exceeded feeder capacity and damaged breakers. - Star-Delta Starting Current

Reduced to about 340 A, well within feeder and breaker capacity. - Torque Consideration

Since conveyors require higher starting torque, engineers included:- Extended timer delay (15–20 seconds) to allow smooth transition.

- Torque calculation margin to ensure loaded start capability.

- Starter Settings

- Main Contactor Rating: 225 A

- Overload Relay Setting: 100–130 A

- Protection Coordination: Verified using IEEE 242 (Buff Book) guidelines.

Result

The conveyor now starts smoothly, mechanical wear is reduced, and protection devices no longer trip unnecessarily. The plant reported longer motor life and reduced downtime.

Practical Guidelines for Engineers

- Load Type Matters

- Pumps, fans, compressors → typically low to medium torque loads → ideal for star-delta.

- Conveyors, crushers, mills → require high starting torque → star-delta may need reinforcement or alternative starting methods.

- Timer Settings

- Too short → transition before motor reaches sufficient speed, causing current spikes.

- Too long → unnecessary stress on star contactor.

- Typical range: 6–20 seconds depending on inertia.

- Contactor Selection

Always size based on 58% (main & delta) and 33% (star) of FLC, per IEEE recommendations. - Overload Protection

Should match the motor’s rated current in delta mode, not star mode. - Power System Compatibility

Star-delta reduces voltage dips on weak grids, making it crucial in industries where power stability is essential.

Extended Reference Table: Common Industrial Applications of Star-Delta Starters

| Industry | Typical Motor Power Range | Application Example | Benefit of Star-Delta |

|---|---|---|---|

| Water Treatment | 11 – 90 kW | Pumps, aerators | Prevents voltage dips, smooth pump start |

| Cement Plants | 30 – 160 kW | Crushers, conveyors | Reduces breaker tripping, protects belts |

| HVAC Systems | 7.5 – 75 kW | Fans, chillers | Lowers inrush current, extends equipment life |

| Mining | 45 – 200 kW | Hoists, compressors | Ensures safe starting under heavy load |

| Food Processing | 15 – 55 kW | Mixers, conveyors | Smooth acceleration, reduced wear |

| Oil & Gas | 22 – 132 kW | Pumps, separators | Compliance with safety and power quality standards |

Advantages and Limitations of Star-Delta Motor Starter

Advantages

- Current reduced to 1/3 of DOL

- Simple and reliable design

- Cost-effective compared to soft starters

- Standardized under IEEE and IEC

Limitations

- Starting torque reduced to 1/3 of DOL torque

- Not suitable for high-torque loads (cranes, mills, crushers)

- Requires three contactors and a timer, increasing control complexity

- Mechanical stress may still occur during star-delta transition

Best Practices According to IEEE Standards

- Use IEEE 3002.7 for protection and coordination studies.

- Refer to IEEE 112 for motor efficiency test methods.

- Apply IEEE 141 (Red Book) for electrical power distribution guidelines.

- Align settings with NEMA MG1 and IEC 60034-1 for motor performance standards.