Converting RPM to kW is essential in mechanical and electrical engineering for accurate motor power estimation.

This process supports energy efficiency, proper equipment sizing, and reliable mechanical power transmission across applications.

RPM to kW (Power) Calculator

How do I convert RPM to kW?

Can I convert RPM to kW without torque?

What’s the difference between shaft kW and input kW?

What units of torque are supported?

Formulas used

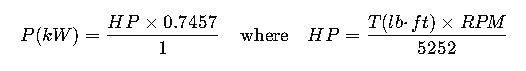

Imperial path: HP = T(lb·ft) × RPM / 5252, then kW = HP × 0.7457.

RPM to kW Conversion Table – Common Values

The following table assumes a constant torque output and performs the conversion using the formula:

Where torque is constant (set at 50 Nm, 100 Nm, and 200 Nm** for typical industrial scenarios). You can use these values directly or as a reference.

Table 1: RPM to kW Conversion for Common Torque Values

| RPM | Power at 50 Nm (kW) | Power at 100 Nm (kW) | Power at 200 Nm (kW) |

|---|---|---|---|

| 100 | 0.52 | 1.05 | 2.09 |

| 250 | 1.31 | 2.62 | 5.24 |

| 500 | 2.62 | 5.24 | 10.47 |

| 750 | 3.93 | 7.85 | 15.71 |

| 1000 | 5.24 | 10.47 | 20.94 |

| 1200 | 6.28 | 12.57 | 25.13 |

| 1500 | 7.85 | 15.71 | 31.42 |

| 1800 | 9.42 | 18.85 | 37.70 |

| 3000 | 15.71 | 31.42 | 62.83 |

These values are based on the widely used formula and are ideal for estimating power output of motors in standard industrial settings.

Key Formulas for RPM to kW Conversion

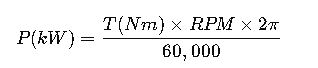

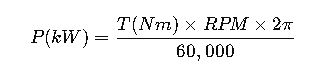

1. Mechanical Power Formula (SI Units)

Variable Breakdown:

- P (Power): Mechanical output power in kilowatts (kW).

- T (Torque): Torque output in Newton-meters (Nm).

- RPM: Rotational speed in revolutions per minute.

- 2π/60,000: Constant to convert from radians per second and watts to kilowatts.

Common Values:

- Small motors: 10–30 Nm

- Medium-size industrial motors: 50–150 Nm

- High-performance motors: 200+ Nm

- RPMs can range from 100 (low-speed gear motors) to 3000+ (high-speed drives).

2. Alternate Formula Using Horsepower (for legacy conversions)

Note:

- 1 Horsepower (HP) ≈ 0.7457 kW

- Torque must be in lb·ft in imperial units

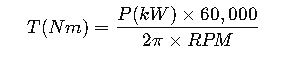

3. Formula Rearranged to Find Torque (if kW and RPM known)

This is essential for reverse-engineering powertrain or gearbox designs when you already know power and speed.

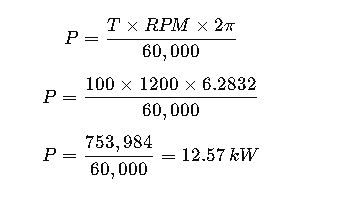

Real-World Application Example 1: Industrial Conveyor Motor Sizing

Problem:

An industrial conveyor runs at RPM = 1200. The manufacturer specifies that the required torque is 100 Nm. What is the required motor power in kW?

Solution:

The system requires a motor with at least 12.57 kW output to ensure proper operation.

Note: Engineers typically add 10-20% service factor, so a 15 kW motor would be selected.

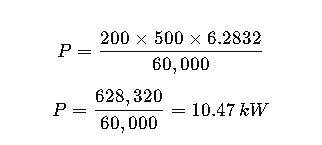

Real-World Application Example 2: Wind Turbine Output Estimation

Problem:

A small wind turbine produces a constant torque of 200 Nm and spins at RPM = 500 under average wind conditions. Estimate the power output.

Solution:

The wind turbine can output about 10.47 kW, making it suitable for small farms or backup energy systems.

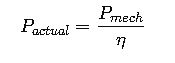

Additional Engineering Considerations

Efficiency Losses

In real-world systems, motor efficiency, gear losses, and thermal effects impact the actual delivered power:

- η (efficiency) is usually between 0.85 to 0.98 for high-quality motors.

- Always account for losses when selecting motors.

Units of Torque

Be cautious with units:

- 1 Nm = 0.7376 lb·ft

- 1 lb·ft = 1.3558 Nm

Many datasheets (especially U.S.-based) use imperial units, so proper unit conversion is crucial.

Extended RPM to kW Table – Fine Granularity

| RPM | Power @ 75 Nm (kW) | Power @ 125 Nm (kW) | Power @ 250 Nm (kW) |

|---|---|---|---|

| 100 | 0.78 | 1.31 | 2.62 |

| 200 | 1.57 | 2.62 | 5.24 |

| 400 | 3.14 | 5.24 | 10.47 |

| 600 | 4.71 | 7.85 | 15.71 |

| 800 | 6.28 | 10.47 | 20.94 |

| 1000 | 7.85 | 13.09 | 26.18 |

| 1250 | 9.81 | 16.36 | 32.73 |

| 1500 | 11.78 | 19.64 | 39.27 |

| 1800 | 14.14 | 23.57 | 47.13 |

| 3000 | 23.56 | 39.27 | 78.54 |

These values help in quick decision-making during drive selection, especially in HVAC systems, gear reducers, wind turbines, and automated conveyor belts.

Tools and Online Resources

To facilitate RPM to kW conversions, you may refer to the following tools:

These are reliable sources frequently used by professional engineers in field applications.

Final Notes on Best Practices

When working with RPM to kW conversions, always:

- Verify torque values under load and peak conditions.

- Use service factors for motor sizing.

- Convert units accurately (SI ↔ Imperial).

- Factor in mechanical losses and real efficiencies.

- Validate sizing with manufacturers’ datasheets and applications notes.

Expand Your Knowledge

For in-depth applications in design and compliance, refer to:

- IEC 60034 – Rotating Electrical Machines standard

- NEMA MG 1 – Motors and Generators by NEMA (U.S.)

- ISO 8528 – Generating sets standards

Understanding these will improve your ability to size equipment, optimize performance, and ensure long-term reliability.