Understanding kilowatt (kW) to kilowatt-hour (kWh) conversion is essential for effective energy management strategies.

This guide explains calculations for single-phase, two-phase, three-phase systems, including formulas, tables, examples.

kW → kWh Calculator

How to calculate kWh?

Why system phase matters?

Standard kW to kWh Conversion Tables

Below are extensive tables showing common power ratings in kW and their corresponding energy consumption in kWh over different time intervals. These tables help engineers and facility managers quickly estimate energy usage.

Single-Phase (1φ) System

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 0.5 | 0.5 | 1 | 2 | 4 | 6 | 12 |

| 1 | 1 | 2 | 4 | 8 | 12 | 24 |

| 2 | 2 | 4 | 8 | 16 | 24 | 48 |

| 3 | 3 | 6 | 12 | 24 | 36 | 72 |

| 5 | 5 | 10 | 20 | 40 | 60 | 120 |

| 7.5 | 7.5 | 15 | 30 | 60 | 90 | 180 |

| 10 | 10 | 20 | 40 | 80 | 120 | 240 |

Two-Phase (2φ) System

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 4 | 8 | 12 | 24 |

| 2 | 2 | 4 | 8 | 16 | 24 | 48 |

| 4 | 4 | 8 | 16 | 32 | 48 | 96 |

| 6 | 6 | 12 | 24 | 48 | 72 | 144 |

| 8 | 8 | 16 | 32 | 64 | 96 | 192 |

| 10 | 10 | 20 | 40 | 80 | 120 | 240 |

Three-Phase (3φ) System

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 1.5 | 1.5 | 3 | 6 | 12 | 18 | 36 |

| 3 | 3 | 6 | 12 | 24 | 36 | 72 |

| 5 | 5 | 10 | 20 | 40 | 60 | 120 |

| 7.5 | 7.5 | 15 | 30 | 60 | 90 | 180 |

| 10 | 10 | 20 | 40 | 80 | 120 | 240 |

| 15 | 15 | 30 | 60 | 120 | 180 | 360 |

| 20 | 20 | 40 | 80 | 160 | 240 | 480 |

Note: These tables assume constant power consumption without fluctuations. Real systems may have variable loads, power factor, and efficiency losses.

kW to kWh Conversion Formulas

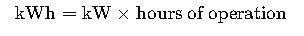

The basic relationship between kW and kWh is:

Where:

- kW = Power rating in kilowatts

- Hours of operation = Time the system is consuming power

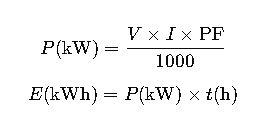

Single-Phase System

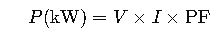

For single-phase AC circuits:

Where:

- V = Voltage in volts (V)

- I = Current in amperes (A)

- PF = Power factor (dimensionless, 0–1)

- t = Time in hours (h)

Typical Values:

| Voltage (V) | Current (A) | PF |

|---|---|---|

| 120 | 10 | 0.8 |

| 230 | 5 | 0.9 |

| 240 | 20 | 1 |

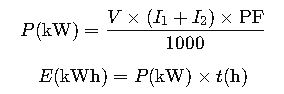

Two-Phase System

Two-phase systems are rare but calculated as:

Where I₁ and I₂ are the currents in each phase.

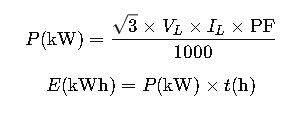

Three-Phase System

For three-phase AC systems:

Where:

- V_L = Line-to-line voltage (V)

- I_L = Line current (A)

- PF = Power factor

- t = Time in hours

Common Three-Phase Configurations:

| Voltage (V_L) | Current (A) | PF |

|---|---|---|

| 208 | 10 | 0.85 |

| 400 | 15 | 0.9 |

| 480 | 20 | 1 |

Real-World Application Examples

Example 1: Single-Phase Residential Load

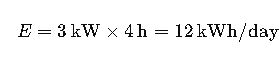

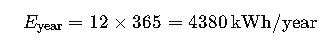

Scenario: A 3 kW electric water heater operates for 4 hours daily.

Calculation:

Annual Consumption:

This value helps estimate electricity bills and load planning for residential energy management.

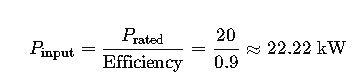

Example 2: Three-Phase Industrial Motor

Scenario: A 15 kW three-phase motor runs 8 hours per day at a PF of 0.9 and voltage of 400 V.

This calculation is essential for industrial energy auditing and load balancing.

Extended kW to kWh Conversion Tables

For professionals managing larger systems, extended tables with higher power ratings are useful. Below are examples for industrial and commercial applications.

Single-Phase Systems (Advanced)

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 12 | 12 | 24 | 48 | 96 | 144 | 288 |

| 15 | 15 | 30 | 60 | 120 | 180 | 360 |

| 20 | 20 | 40 | 80 | 160 | 240 | 480 |

| 25 | 25 | 50 | 100 | 200 | 300 | 600 |

| 30 | 30 | 60 | 120 | 240 | 360 | 720 |

Two-Phase Systems (Advanced)

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 12 | 12 | 24 | 48 | 96 | 144 | 288 |

| 16 | 16 | 32 | 64 | 128 | 192 | 384 |

| 20 | 20 | 40 | 80 | 160 | 240 | 480 |

| 25 | 25 | 50 | 100 | 200 | 300 | 600 |

| 30 | 30 | 60 | 120 | 240 | 360 | 720 |

Three-Phase Systems (Advanced)

| Power (kW) | 1 Hour (kWh) | 2 Hours (kWh) | 4 Hours (kWh) | 8 Hours (kWh) | 12 Hours (kWh) | 24 Hours (kWh) |

|---|---|---|---|---|---|---|

| 25 | 25 | 50 | 100 | 200 | 300 | 600 |

| 30 | 30 | 60 | 120 | 240 | 360 | 720 |

| 40 | 40 | 80 | 160 | 320 | 480 | 960 |

| 50 | 50 | 100 | 200 | 400 | 600 | 1200 |

| 60 | 60 | 120 | 240 | 480 | 720 | 1440 |

Tip: These tables are ideal for industrial engineers estimating daily, monthly, or annual energy consumption for factories, HVAC systems, or production lines.

Power Factor and Its Impact on kWh Calculation

Power factor (PF) significantly influences energy calculations, especially in commercial and industrial setups.

- PF = 1 (Unity): Ideal, all power is active.

- PF < 1: Presence of reactive power; only part of power is active.

Typical PF values:

| Equipment Type | PF Range |

|---|---|

| Electric motors | 0.75–0.9 |

| Lighting (LED/CFL) | 0.9–1 |

| HVAC systems | 0.8–0.95 |

| Industrial machinery | 0.7–0.9 |

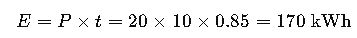

Example: A 20 kW motor with PF = 0.85 running 10 hours:

Real-World Applications: Commercial and Industrial

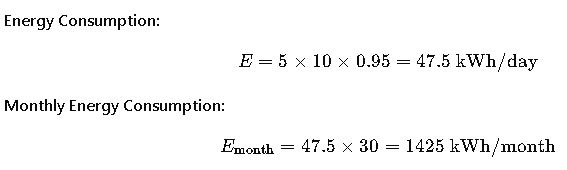

Example 3: Commercial Building Lighting System (Single-Phase)

- Load: 5 kW

- Operating hours: 10 hours/day

- PF: 0.95

This allows facility managers to estimate monthly bills and optimize lighting schedules.

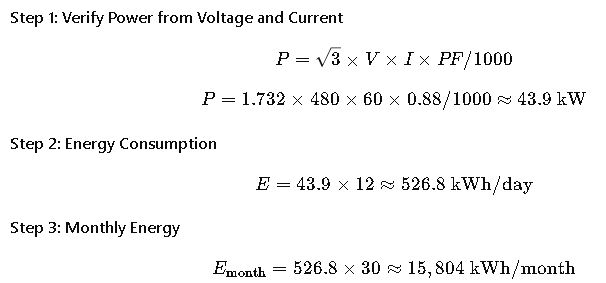

Example 4: Industrial Three-Phase Compressor

- Rated Power: 50 kW

- Voltage: 480 V

- Current: 60 A

- PF: 0.88

- Operating time: 12 hours/day

This helps industrial engineers plan for peak demand, utility contracts, and energy efficiency upgrades.

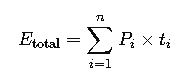

Calculating Energy for Variable Loads

Real systems rarely run at constant power. To calculate kWh for variable loads:

Where Pi is the power during interval ti.

Example: A machine operates:

- 5 kW for 4 hours

- 7 kW for 2 hours

- 3 kW for 6 hours

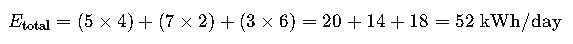

Advanced Considerations

- Efficiency: Motor efficiency affects actual consumption. For example, 90% efficient motor increases energy drawn:

- Voltage Fluctuations: Variations affect current draw; monitor via power meters.

- Time-of-Use (TOU) Tariffs: Energy cost can be minimized by scheduling high loads in off-peak hours.

- Regulatory Standards: Follow IEEE 141 and IEC 60364 for safe calculations and compliance.