Converting kilowatts (kW) to kilovolt-amperes (kVA) is essential in electrical engineering, energy management, and industry. The kW-kVA relationship influences sizing of generators, transformers, UPS systems, ensuring efficiency, reliability, and compliance.

Calculator: kW → kVA (Kilowatts to Kilovolt-amperes)

How to convert kW to kVA?

Which PF should I use?

Understanding the Relationship Between kW and kVA

- kW (kilowatts): Represents the real power consumed or produced by equipment. It measures the actual work output (e.g., mechanical work, lighting, heating).

- kVA (kilovolt-amperes): Represents the apparent power, which includes both real power (kW) and reactive power (kVAR).

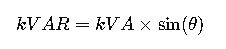

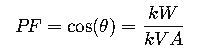

- Power Factor (PF): The ratio of kW to kVA. It quantifies how effectively electrical power is converted into useful work.

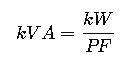

The fundamental equation is:

Where:

- kW = real power (work-producing component).

- kVA = apparent power (total supplied).

- PF = power factor (dimensionless, between 0 and 1).

In most industrial and commercial contexts, the power factor typically ranges from 0.6 to 1.0, with common values around 0.8 to 0.9 for equipment like generators and motors.

Extensive Conversion Tables: kW to kVA at Common Power Factors

The following tables provide ready-to-use conversions for typical industrial and commercial power factor values. These are designed for engineers, facility planners, and technicians who need quick reference without manually calculating.

Table 1. Conversion of kW to kVA at Power Factor = 1.0 (Unity PF)

| kW | kVA |

|---|---|

| 10 | 10 |

| 20 | 20 |

| 50 | 50 |

| 75 | 75 |

| 100 | 100 |

| 150 | 150 |

| 200 | 200 |

| 250 | 250 |

| 300 | 300 |

| 400 | 400 |

| 500 | 500 |

| 750 | 750 |

| 1000 | 1000 |

| 2000 | 2000 |

| 3000 | 3000 |

| 5000 | 5000 |

At PF = 1.0, kW = kVA, since all supplied power is converted into useful work.

Table 2. Conversion of kW to kVA at Power Factor = 0.8 (Common Industrial PF)

| kW | kVA |

|---|---|

| 10 | 12.5 |

| 20 | 25 |

| 50 | 62.5 |

| 75 | 93.8 |

| 100 | 125 |

| 150 | 187.5 |

| 200 | 250 |

| 250 | 312.5 |

| 300 | 375 |

| 400 | 500 |

| 500 | 625 |

| 750 | 937.5 |

| 1000 | 1250 |

| 2000 | 2500 |

| 3000 | 3750 |

| 5000 | 6250 |

At PF = 0.8, apparent power is larger than real power, meaning equipment needs more supply capacity.

Table 3. Conversion of kW to kVA at Power Factor = 0.9

| kW | kVA |

|---|---|

| 10 | 11.1 |

| 20 | 22.2 |

| 50 | 55.6 |

| 75 | 83.3 |

| 100 | 111.1 |

| 150 | 166.7 |

| 200 | 222.2 |

| 250 | 277.8 |

| 300 | 333.3 |

| 400 | 444.4 |

| 500 | 555.6 |

| 750 | 833.3 |

| 1000 | 1111.1 |

| 2000 | 2222.2 |

| 3000 | 3333.3 |

| 5000 | 5555.6 |

A PF of 0.9 is typically found in optimized power systems with correction capacitors installed.

Table 4. Conversion of kW to kVA at Power Factor = 0.6 (Low PF Scenario)

| kW | kVA |

|---|---|

| 10 | 16.7 |

| 20 | 33.3 |

| 50 | 83.3 |

| 75 | 125 |

| 100 | 166.7 |

| 150 | 250 |

| 200 | 333.3 |

| 250 | 416.7 |

| 300 | 500 |

| 400 | 666.7 |

| 500 | 833.3 |

| 750 | 1250 |

| 1000 | 1666.7 |

| 2000 | 3333.3 |

| 3000 | 5000 |

| 5000 | 8333.3 |

A low PF scenario is common in poorly corrected systems, such as those with large inductive motor loads.

Formulas for Calculator kW to kVA

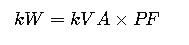

The fundamental equation:

But to deepen understanding, let’s explore all related formulas:

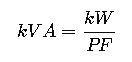

1.Power Triangle Relationship

- kVA = apparent power

- kW = real power

- kVAR = reactive power

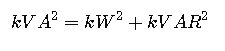

2.Reactive Power Calculation

Where θ = phase angle between current and voltage.

3.Power Factor Definition

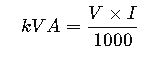

4.kVA from Current and Voltage (Single Phase)

Where:

- V = Voltage in Volts

- I = Current in Amperes

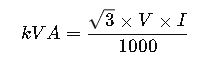

5.kVA from Current and Voltage (Three Phase)

6.kW from kVA and PF

Explanation of Variables

- kW (kilowatts): Energy doing real work, measured in kilojoules per second.

- kVA (kilovolt-amperes): Total energy supplied (real + reactive).

- kVAR (kilovolt-ampere reactive): Power oscillating between source and load, not doing useful work.

- PF (power factor): Ratio of useful work to total supplied power.

- V: Voltage in the system (V).

- I: Current drawn by load (A).

- θ: Phase angle between current and voltage (degrees or radians).

Real-World Applications of kW to kVA Conversion

Case Study 1: Generator Sizing for a Data Center

Scenario:

A data center has a continuous load requirement of 800 kW with an average power factor of 0.85. The facility manager needs to select a backup generator.

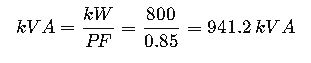

Step 1: Apply formula

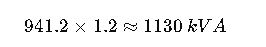

Step 2: Safety margin

Industrial practice recommends sizing the generator at 20% above calculated kVA to account for transient loads.

Solution:

The appropriate generator size is 1130 kVA, ensuring reliability and preventing overloads.

Implications:

- Without conversion, choosing an 800 kVA generator would lead to undersizing.

- This could cause overheating, reduced lifespan, and potential downtime.

Case Study 2: Transformer Sizing in an Industrial Plant

Scenario:

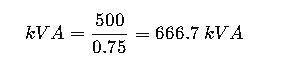

An industrial facility runs induction motors totaling 500 kW at a PF of 0.75. Engineers must size the transformer.

Step 1: Calculate required kVA

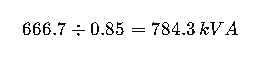

Step 2: Apply transformer selection standards

According to IEC 60076 and IEEE C57 standards, transformers should operate below 85% of rated capacity for longevity.

Solution:

A 800 kVA transformer should be selected.

Engineering Note:

This ensures future load growth capacity and compliance with reliability standards.

Practical Applications Across Industries

1. Data Centers and IT Infrastructure

Data centers operate with highly sensitive loads and strict uptime requirements. Converting kW to kVA is fundamental for:

- Sizing UPS systems: Manufacturers rate UPS capacity in kVA, but IT loads are measured in kW. Engineers must convert accurately to avoid undersizing.

- Generator backup systems: Continuous and peak loads are often expressed in kW, while generators are rated in kVA.

A typical example: A 600 kW IT load at 0.9 PF requires a 667 kVA UPS. If the PF drops unexpectedly, the same UPS may be overloaded, risking downtime.

2. Industrial Manufacturing Plants

In manufacturing plants, most equipment is inductive in nature (motors, pumps, conveyors). Engineers must calculate kVA demand to select:

- Transformers: Rated in kVA, not kW.

- Switchgear: Needs to handle both real and apparent power.

- Cabling systems: Oversized if reactive power is excessive.

If a plant consumes 1200 kW with a PF of 0.75, the actual kVA is much higher, forcing larger investment in infrastructure.

3. Renewable Energy Systems

Solar inverters, wind turbines, and hybrid microgrids all require kW to kVA conversion for:

- Grid compliance: Utilities impose power factor requirements on renewable systems.

- Inverter sizing: Inverters are often rated in kVA, while load consumption is expressed in kW.

- Battery energy storage systems: Must provide both active and reactive power support.

A solar farm delivering 1000 kW at PF 0.9 requires an inverter of at least 1110 kVA capacity.

4. Commercial Buildings

Shopping malls, hospitals, airports, and office towers all require precise sizing of electrical equipment. The typical PF in these environments ranges from 0.85 to 0.95. Without proper conversion:

- HVAC systems could overload distribution boards.

- Elevators and escalators might trigger overcurrent protection unnecessarily.

- Backup power systems might be undersized, failing during outages.

Advanced Considerations in kW to kVA Conversion

Effect of Low Power Factor

A low PF increases the apparent power (kVA) demand significantly. This has three main impacts:

- Higher equipment costs: Larger generators, transformers, and cables are required.

- Lower efficiency: More current flows through the system, leading to heat losses.

- Utility penalties: Many utilities charge additional fees when PF falls below 0.9.

Power Factor Correction

The most common solution is to install capacitor banks or active harmonic filters. These devices improve PF by compensating for the reactive component, bringing the system closer to unity PF. This reduces kVA demand and makes equipment run more efficiently.

For example, a plant operating at 0.7 PF may improve to 0.95 PF after installing capacitors, reducing its kVA demand by over 25% without changing its kW load.

How to Use a kW to kVA Calculator Effectively

An online calculator simplifies the conversion process. To use it properly:

- Enter the kW value: Based on the load requirement.

- Select or input the PF: If unknown, assume 0.8 (common industrial standard) or measure with a power quality analyzer.

- Obtain kVA result: The calculator will instantly show the apparent power.

- Apply safety margin: Always add 15–25% margin for future expansion or transient loads.

For accurate engineering design, it’s critical to base the PF on actual measurements rather than assumptions.

Frequently Asked Questions (FAQ)

1. Why do generators use kVA rating instead of kW?

Because generators supply both real and reactive power, and manufacturers cannot predict the exact PF of the connected loads. Rating in kVA provides a universal measure.

2. What is a good power factor to assume?

For general industrial applications, 0.8 PF is often used as a conservative estimate. Modern equipment with correction systems can achieve 0.9–0.95 PF.

3. Can PF be greater than 1?

No. In practice, PF ranges from 0 to 1. However, some meters may display values slightly above 1 due to measurement errors.

4. How do I know the PF of my system?

Use a power quality analyzer or check your utility bill. Many utilities display average PF on monthly reports.

5. What happens if I undersize equipment due to ignoring PF?

Undersized transformers, UPS systems, or generators will overheat, trip protections, and reduce operational reliability.