Understanding the conversion from amperes to kilowatts is essential for engineers, electricians, and power professionals. This guide explores formulas, common values, real-world applications, and practical examples for thorough comprehension.

Amperes (A) to Kilowatts (kW) Calculator

What PF to use if unknown?

Voltage selection (L–N vs L–L)?

Formulas used

Three-phase: kW = (√3 × V × A × PF) / 1000.

DC: kW = (V × A) / 1000.

Conversion Formulas

The conversion from amps to kilowatts varies based on the type of electrical system: Direct Current (DC), Single-Phase Alternating Current (AC), or Three-Phase AC. Below are the standard formulas used:

1. Direct Current (DC)

For DC systems, the formula is straightforward:

This formula assumes a power factor of 1, as DC systems do not have reactive components.

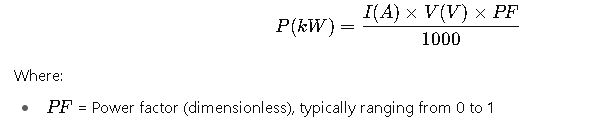

2. Single-Phase AC

In single-phase AC systems, the formula incorporates the power factor (PF):

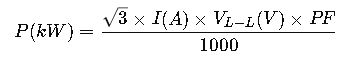

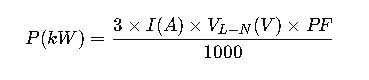

3. Three-Phase AC

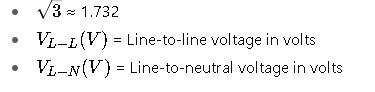

For three-phase AC systems, there are two variations depending on the voltage type:

a. Line-to-Line Voltage

b. Line-to-Neutral Voltage

Where:

Common Power Factor Values

The power factor varies depending on the type of load. Below are typical values:

| Load Type | Power Factor (PF) |

|---|---|

| Resistive (e.g., heaters) | 1.0 |

| Fluorescent lighting | 0.95 |

| Incandescent lighting | 1.0 |

| Induction motor (full load) | 0.85 |

| Induction motor (no load) | 0.35 |

| Synchronous motor | 0.9 |

Note: Always use the actual power factor for accurate calculations.

Conversion Tables

Below are conversion tables for various systems, assuming a power factor of 1.0 (ideal for resistive loads):

DC System (Power Factor = 1)

| Current (A) | Voltage (V) | Power (kW) |

|---|---|---|

| 10 | 120 | 1.2 |

| 20 | 120 | 2.4 |

| 30 | 120 | 3.6 |

| 40 | 120 | 4.8 |

| 50 | 120 | 6.0 |

Single-Phase AC System (Power Factor = 1)

| Current (A) | Voltage (V) | Power (kW) |

|---|---|---|

| 10 | 120 | 1.2 |

| 20 | 120 | 2.4 |

| 30 | 120 | 3.6 |

| 40 | 120 | 4.8 |

| 50 | 120 | 6.0 |

Three-Phase AC System (Line-to-Line Voltage, Power Factor = 1)

| Current (A) | Voltage (V) | Power (kW) |

|---|---|---|

| 10 | 400 | 6.93 |

| 20 | 400 | 13.86 |

| 30 | 400 | 20.79 |

| 40 | 400 | 27.72 |

| 50 | 400 | 34.65 |

Note: For three-phase systems, ensure to use the correct voltage type (line-to-line or line-to-neutral) and power factor.

Detailed Example Calculations

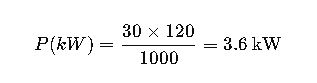

Example 1: DC System

Given:

- Current (I) = 30 A

- Voltage (V) = 120 V

Calculation:

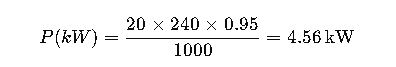

Example 2: Single-Phase AC System

Given:

- Current (I) = 20 A

- Voltage (V) = 240 V

- Power Factor (PF) = 0.95

Calculation:

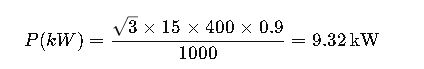

Example 3: Three-Phase AC System (Line-to-Line Voltage)

Given:

- Current (I) = 15 A

- Voltage (VL−L) = 400 V

- Power Factor (PF) = 0.9

Calculation:

Practical Applications

1. Sizing Electrical Circuits

Accurate conversion from amps to kilowatts is essential for determining the appropriate wire sizes, circuit breakers, and other components in electrical installations. This ensures safety and efficiency in the system.

2. Energy Management

Understanding the power consumption in kilowatts helps in monitoring and managing energy usage, leading to cost savings and optimized energy consumption.

3. System Design

In designing electrical systems, especially in industrial settings, converting amps to kilowatts aids in selecting the right equipment and ensuring the system meets the required specifications.

Understanding Electrical Power in Professional Applications

Converting current to power is not just a mathematical exercise—it plays a critical role in the design, operation, and optimization of electrical systems. Professionals rely on accurate current-to-power conversion for tasks such as load analysis, energy efficiency calculations, and compliance with industrial standards.

Electrical power measured in kilowatts allows engineers to estimate the energy consumption of machinery, heating, cooling, and lighting systems. Accurate knowledge of power consumption is crucial for optimizing operational costs, avoiding overloading circuits, and ensuring long-term reliability of electrical infrastructure.

Factors Affecting Power Calculation in Real-World Systems

1. Power Factor Variability

While theoretical calculations often assume ideal conditions, real-world systems rarely operate at perfect efficiency. The power factor represents how effectively electrical power is converted into useful work. Equipment like motors, transformers, and fluorescent lighting may operate at reduced efficiency, causing a discrepancy between theoretical and actual power usage. Understanding the specific power factor of equipment ensures precise system sizing and prevents oversizing or undersizing components.

2. Voltage Fluctuations

Electrical systems are subject to voltage variations due to load changes, grid disturbances, and long-distance transmission losses. Designers must account for these fluctuations to maintain operational safety and efficiency. Overestimating voltage can lead to oversized wiring and equipment costs, while underestimating it can cause overheating and premature failure of components.

3. Load Type and Operating Conditions

Different loads exhibit unique electrical characteristics:

- Resistive loads, such as heating elements, consume power in a predictable linear manner.

- Inductive loads, such as motors, produce reactive power, which requires careful attention to avoid inefficiencies.

- Capacitive loads can affect voltage stability and may lead to overcompensation if not properly analyzed.

Accurate measurement of actual operating conditions is essential for reliable system design and effective energy management.

Advanced Applications in Industrial and Commercial Settings

Industrial Machinery Design

In large industrial environments, engineers often deal with high-power motors, conveyors, and processing equipment. Understanding the current-to-power relationship allows for precise motor sizing, proper selection of protective devices, and accurate load balancing. Correct sizing prevents excessive energy loss and reduces maintenance costs.

Renewable Energy Integration

In solar photovoltaic (PV) systems and wind turbines, current-to-power conversions are crucial for determining inverter capacity, battery storage requirements, and grid interaction. Engineers must analyze fluctuating currents caused by varying sunlight or wind speeds to optimize energy capture and ensure compliance with grid regulations.

Energy Auditing and Cost Analysis

Commercial facilities perform detailed energy audits to identify areas of excessive energy consumption. Accurate conversion of current measurements into kilowatts enables facility managers to determine energy costs, optimize HVAC systems, and improve overall energy efficiency. These insights can translate directly into cost savings and reduced carbon footprint.

Benefits of Using Amp-to-kW Calculators Professionally

- Improved Safety: Accurate calculations reduce the risk of circuit overloading, electrical fires, and equipment damage.

- Cost Optimization: Proper system sizing prevents unnecessary expenditure on oversized equipment and minimizes energy waste.

- Regulatory Compliance: Many industrial standards require precise documentation of energy usage and electrical loads. Accurate power measurements facilitate compliance.

- Performance Optimization: Real-time monitoring of current and power allows engineers to adjust operational parameters for maximum efficiency.

Real-World Case Study 1: Industrial Motor Installation

A manufacturing facility is planning to install a series of three-phase motors to operate conveyor belts. Engineers measure the current and know the line voltage and approximate power factor. By converting current to kilowatts, they determine the total energy requirements for the facility and ensure that transformers, circuit breakers, and protective devices are properly rated. This prevents downtime due to overcurrent events and ensures that energy consumption is accurately forecasted.

Real-World Case Study 2: Solar Farm Power Analysis

An engineer managing a solar farm monitors the current output of several PV arrays. By converting the measured current into kilowatts, the engineer can calculate the total energy production in real-time. This data is used to determine battery storage needs, schedule maintenance, and plan energy sales to the grid. Using this approach, the solar farm maximizes efficiency and ensures the reliability of energy supply.

Leveraging Amp-to-kW Conversion for Strategic Decisions

Beyond technical design, understanding the relationship between current and power supports strategic decision-making. Facility managers can:

- Schedule high-energy operations during off-peak hours to reduce utility costs.

- Identify underperforming equipment based on actual power consumption.

- Design predictive maintenance schedules using energy usage patterns.

This data-driven approach transforms raw electrical measurements into actionable intelligence, improving both operational efficiency and sustainability.

References and Authority Resources

For further study and validation of industry standards, consult:

- IEEE Standards for Power and Energy Measurements – IEEE Xplore

- Schneider Electric Electrical Calculation Guides – Schneider Electric

- Electrical Engineering Portal – EEP