Uninterruptible Power Supply (UPS) power factor correction is critical for optimizing electrical efficiency and reducing energy costs. Accurate calculation ensures compliance with IEEE and IEC standards, improving system reliability.

This article explores advanced UPS power factor correction calculations, including formulas, tables, and real-world examples. It covers IEEE and IEC guidelines to help engineers and technicians optimize UPS performance.

Artificial Intelligence (AI) Calculator for “UPS Power Factor Correction Calculator – IEEE, IEC”

- Calculate required capacitor size for a 50 kVA UPS with 0.7 lagging power factor to reach 0.95.

- Determine corrected power factor for a 30 kW load with 0.85 lagging power factor and 400 V supply.

- Find reactive power compensation needed for a 100 kVA UPS operating at 0.75 lagging power factor.

- Calculate new apparent power after power factor correction from 0.6 to 0.9 for a 20 kW load.

Common Values for UPS Power Factor Correction – IEEE and IEC Standards

| Parameter | Typical Range | Units | Notes |

|---|---|---|---|

| Power Factor (PF) Before Correction | 0.6 – 0.85 (lagging) | Unitless | Typical UPS loads with inductive components |

| Target Power Factor (PF) After Correction | 0.95 – 0.99 (leading or unity) | Unitless | Recommended by IEEE 519 and IEC 61000-3-2 |

| Apparent Power (S) | 10 – 1000 | kVA | UPS rating range for industrial applications |

| Active Power (P) | 5 – 900 | kW | Real power consumed by load |

| Reactive Power (Q) | 3 – 600 | kVAR | Inductive or capacitive power component |

| Supply Voltage (V) | 230 / 400 / 480 | Volts (V) | Common industrial and commercial voltages |

| Frequency (f) | 50 / 60 | Hz | Standard power system frequencies |

| Capacitor Size (C) | 5 – 500 | µF or kVAR | Capacitive reactive power for correction |

Fundamental Formulas for UPS Power Factor Correction

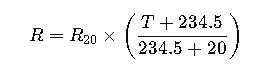

Power factor correction involves adjusting the reactive power to improve the overall power factor of the UPS system. The following formulas are essential for calculating the required capacitor size and understanding the power relationships.

1. Power Factor (PF)

The power factor is the ratio of active power to apparent power:

- P = Active power (kW)

- S = Apparent power (kVA)

- PF = Power factor (unitless, between 0 and 1)

2. Apparent Power (S)

Apparent power is the vector sum of active and reactive power:

- Q = Reactive power (kVAR)

3. Reactive Power (Q)

Reactive power can be calculated from apparent and active power:

4. Required Reactive Power Compensation (Qc)

To correct the power factor from an initial value (PF1) to a target value (PF2), the required reactive power compensation is:

- θ1 = arccos(PF1) (initial power factor angle)

- θ2 = arccos(PF2) (target power factor angle)

- Qc = Capacitive reactive power needed (kVAR)

5. Capacitor Size (C) in Microfarads (µF)

For single-phase systems, capacitor size can be calculated as:

- C = Capacitance (µF)

- Qc = Reactive power compensation (VAR)

- f = Frequency (Hz)

- V = RMS voltage (Volts)

For three-phase systems, capacitor size per phase is:

6. Corrected Apparent Power (S2)

After power factor correction, the new apparent power is:

Detailed Real-World Examples of UPS Power Factor Correction

Example 1: Capacitor Size Calculation for a 50 kVA UPS

A 50 kVA UPS operates at 0.7 lagging power factor. The goal is to improve the power factor to 0.95 lagging. The supply voltage is 400 V, and frequency is 50 Hz. Calculate the required capacitor size for power factor correction.

- Given:

- S1 = 50 kVA

- PF1 = 0.7 (lagging)

- PF2 = 0.95 (lagging)

- V = 400 V (line-to-line)

- f = 50 Hz

Step 1: Calculate active power (P)

Step 2: Calculate initial and target power factor angles

θ2 = arccos(0.95) ≈ 18.19°

Step 3: Calculate reactive power compensation (Qc)

Calculate tangents:

- tan 45.57° ≈ 1.02

- tan 18.19° ≈ 0.33

Therefore:

Step 4: Calculate capacitor size (C) for three-phase system

Convert Qc to VAR:

Use formula:

Calculate denominator:

- 3 × 2 × π × 50 × (400)² = 3 × 2 × 3.1416 × 50 × 160,000 = 3 × 2 × 3.1416 × 8,000,000 = 3 × 2 × 25,132,741 = 150,796,447

Calculate capacitance:

Result: Install a three-phase capacitor bank of approximately 160 µF per phase to correct the power factor.

Example 2: Corrected Apparent Power and Load Analysis

A 30 kW UPS load operates at 0.85 lagging power factor with a supply voltage of 230 V and frequency of 60 Hz. Calculate the corrected apparent power after improving power factor to 0.98.

- Given:

- P = 30 kW

- PF1 = 0.85

- PF2 = 0.98

- V = 230 V

- f = 60 Hz

Step 1: Calculate initial apparent power (S1)

Step 2: Calculate corrected apparent power (S2)

Step 3: Calculate reactive power before and after correction

- Q1 = √(S1² – P²) = √(35.29² – 30²) = √(1245.4 – 900) = √345.4 ≈ 18.59 kVAR

- Q2 = √(S2² – P²) = √(30.61² – 30²) = √(936.9 – 900) = √36.9 ≈ 6.07 kVAR

Step 4: Calculate reactive power compensation (Qc)

Step 5: Calculate capacitor size for single-phase system

Convert Qc to VAR:

Use formula:

Calculate denominator:

- 2 × π × 60 × (230)² = 2 × 3.1416 × 60 × 52,900 = 2 × 3.1416 × 3,174,000 = 2 × 9,973,440 = 19,946,880

Calculate capacitance:

Result: A capacitor bank of approximately 628 µF is required to improve the power factor to 0.98.

Additional Technical Considerations for UPS Power Factor Correction

- IEEE 519 Compliance: IEEE 519 standard limits harmonic distortion and recommends power factor correction to reduce reactive power and improve system stability.

- IEC 61000-3-2 Guidelines: IEC standards specify limits on harmonic currents and recommend power factor correction to minimize power quality issues.

- Harmonic Distortion Impact: UPS systems often generate harmonics; capacitor banks must be designed to avoid resonance and harmonic amplification.

- Dynamic vs. Static Correction: Static capacitors provide fixed correction, while dynamic systems (using power electronics) adapt to load changes for optimal correction.

- Measurement Accuracy: Use true RMS meters and power analyzers compliant with IEC 61000-4-30 for accurate power factor and harmonic measurements.

- Safety and Protection: Capacitor banks require fuses, contactors, and protection relays to prevent damage from faults or switching transients.

Summary of Key Parameters and Their Typical Values

| Parameter | Typical Value | Unit | Description |

|---|---|---|---|

| Power Factor (PF) | 0.7 – 0.99 | Unitless | Ratio of active to apparent power |

| Reactive Power (Q) | 5 – 600 | kVAR | Power stored and released by inductors/capacitors |

| Capacitor Size (C) | 50 – 500 | µF | Capacitance required for correction |

| Voltage (V) | 230 / 400 / 480 | Volts | Supply voltage levels |

| Frequency (f) | 50 / 60 | Hz | Power system frequency |

References and Further Reading

- IEEE Std 519-2014 – IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems

- IEC 61000-3-2 – Electromagnetic compatibility (EMC) – Limits for harmonic current emissions

- Schneider Electric – Power Factor Correction Guide

- Eaton – Power Factor Correction Solutions