Tonnage calculation is crucial in industries like structural engineering, manufacturing, and mechanical design processes.

Accurate tonnage calculation ensures correct equipment sizing, safety, material estimation, cost control, and efficiency.

Tonnage Calculation

Common Tonnage Values Across Applications

The following tables present reference values for tonnage across various materials, operations, and structural elements. These values are typical in industrial contexts and useful for quick estimation before precise calculations.

Table 1: Common Material Thickness and Required Tonnage (Sheet Metal Bending – Mild Steel)

| Thickness (mm) | Die Opening (mm) | Tonnage per Meter (Metric Ton/m) |

|---|---|---|

| 0.8 | 10 | 5 |

| 1.0 | 12 | 6.2 |

| 1.5 | 16 | 9.4 |

| 2.0 | 20 | 12.4 |

| 3.0 | 32 | 18.7 |

| 4.0 | 40 | 25 |

| 5.0 | 50 | 31.2 |

| 6.0 | 63 | 37.5 |

| 8.0 | 80 | 50 |

| 10.0 | 100 | 62.5 |

Source: American Iron and Steel Institute, adapted for press brake forming source

Table 2: Tonnage Requirements for Punching Mild Steel (per mm of thickness and mm of perimeter)

| Thickness (mm) | Punching Force per mm Perimeter (kN/mm) |

|---|---|

| 1 | 2.2 |

| 2 | 4.4 |

| 3 | 6.6 |

| 4 | 8.8 |

| 5 | 11 |

| 6 | 13.2 |

| 8 | 17.6 |

| 10 | 22 |

Table 3: Standard Unit Weights of Common Structural Shapes (used in Tonnage for Steel Estimation)

| Steel Shape | Weight per Meter (kg/m) |

|---|---|

| IPE 100 | 8.1 |

| IPE 200 | 20.9 |

| HEA 200 | 61.3 |

| Rectangular Tube 80x40x3 | 8.55 |

| Plate 10mm thick | 78.5 (per m²) |

Key Formulas for Tonnage Calculation

There are different formulas depending on the operation (bending, punching, forming, shearing, or structural loading). Below are the primary ones with detailed variable breakdowns.

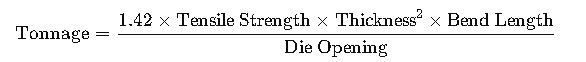

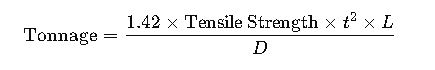

1. Bending Tonnage (Press Brake)

Variables Explained:

- Tensile Strength (N/mm²): For mild steel ≈ 450 N/mm²

- Thickness (mm): Thickness of the material to be bent

- Bend Length (mm): Length of the bend

- Die Opening (mm): V-die opening, typically 8 × thickness

Typical Values:

- For aluminum: 310 N/mm²

- For stainless steel: 600 N/mm²

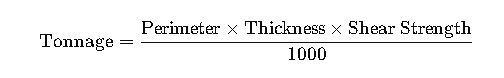

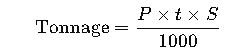

2. Punching Force

Variables Explained:

- Perimeter (mm): Total edge length being punched

- Thickness (mm): Sheet thickness

- Shear Strength (N/mm²): For mild steel ≈ 300 N/mm²

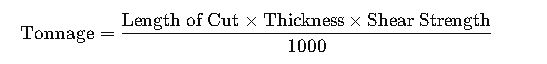

3. Shearing Force

Same variables as punching, but for straight cuts.

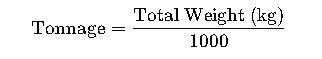

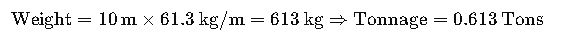

4. Structural Tonnage Estimate (for steel structures)

- Weight = Σ(length × weight per meter) for all members

Example for I-beam:

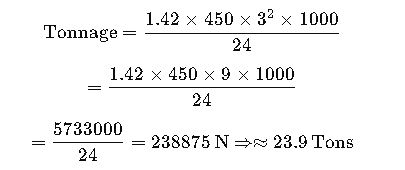

Real-World Example 1: Bending a Mild Steel Sheet (Press Brake)

Problem:

You need to bend a 3 mm thick mild steel sheet across a length of 1000 mm using a 24 mm V-die.

Data:

- Thickness = 3 mm

- Bend Length = 1000 mm

- Die Opening = 24 mm (8× thickness)

- Tensile Strength = 450 N/mm²

Solution:

Using bending tonnage formula:

Interpretation:

You need a 24-ton press brake to bend this sheet safely. It’s advised to add a 20% safety margin, so select a 30-ton capacity machine.

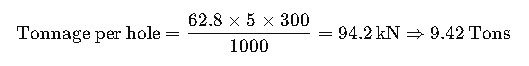

Real-World Example 2: Punching Holes in a Steel Plate

Problem:

Punch 10 circular holes (Ø20 mm) in a 5 mm thick mild steel plate.

Data:

- Perimeter = π × diameter = 3.14 × 20 = 62.8 mm

- Thickness = 5 mm

- Shear Strength = 300 N/mm²

Calculation per hole:

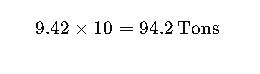

For 10 holes:

Safety Factors and Industry Standards

In practice, tonnage calculations are adjusted by applying safety factors to accommodate material variations, machine inefficiencies, and operator errors.

- Typical safety factor: 1.1 to 1.3 (10-30%)

- Industry standards:

- ISO 9001: Quality management for manufacturing processes.

- AISC (American Institute of Steel Construction): Steel structure design guidelines.

- ANSI: American National Standards for mechanical press safety.

- EN 1011: Welding and fabrication standards.

Practical Notes on Tonnage Measurement and Control

- Modern press brakes and shearing machines are equipped with tonnage sensors and load cells that continuously monitor force applied.

- Real-time monitoring ensures no overloading, reducing wear and potential damage.

- Calibration is crucial: tonnage values can drift due to wear or misalignment.

- Regular maintenance and inspection are mandated by safety regulations.

Frequently Asked Questions (SEO-Optimized)

What is the best formula for calculating bending tonnage?

The most commonly used formula is:

Where all variables must be in consistent units (N/mm², mm).

How do I calculate the tonnage required to punch holes in steel?

Multiply the perimeter of the hole(s) by thickness and shear strength, then divide by 1000 to convert to tons:

What safety factor should be considered in tonnage calculations?

Typically, a 10-30% safety margin is added to account for uncertainties in material properties and machine efficiency.