Storage tank dimension calculations ensure safe, efficient liquid containment, accounting for structural, operational, and environmental constraints. Engineers optimize height, diameter, material, and foundation while complying with API 650, ISO, and ASME standards.

Tank Dimension Calculator

How is the tank volume calculated?

Units

Common Tank Dimensions Table

The following table presents typical tank dimensions based on API 650 standards, commonly used in the oil and gas industry:

| Tank Diameter (ft) | Tank Height (ft) | Nominal Capacity (bbl) | Nominal Capacity (m³) |

|---|---|---|---|

| 30 | 30 | 1,000 | 159.0 |

| 40 | 40 | 2,500 | 397.5 |

| 50 | 50 | 5,000 | 795.0 |

| 60 | 60 | 10,000 | 1,590.0 |

| 70 | 70 | 15,000 | 2,385.0 |

| 80 | 80 | 20,000 | 3,180.0 |

Note: Capacities are approximate and can vary based on design specifics.

Formulas for Tank Dimension Calculation

To determine the dimensions of a tank, several formulas are employed, primarily focusing on the relationship between volume, diameter, and height.

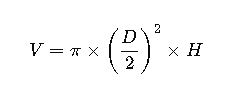

1.Volume of a Cylindrical Tank:

Where:

- V= Volume (bbl or m³)

- D= Diameter (ft or m)

- H= Height (ft or m)

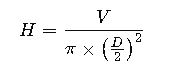

2.Height Calculation:

- This formula is used when the volume and diameter are known, and the height needs to be determined.

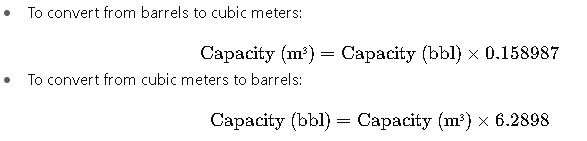

3.Nominal Capacity Conversion:

- 1 barrel (bbl) = 0.158987 m³

Real-World Application Examples

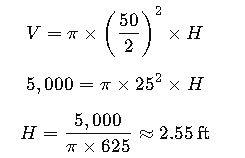

1.Example 1: Determining Tank Height

- Given:

- Desired capacity: 5,000 bbl

- Tank diameter: 50 ft

- Using the volume formula:

Therefore, the tank height required is approximately 2.55 feet.

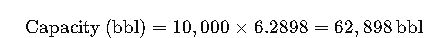

2.Example 2: Converting Capacity Units

- Given:

- Capacity: 10,000 m³

- To convert to barrels:

- Therefore, the capacity is 62,898 barrels.

Tank Dimensioning: Key Technical Considerations

Designing a storage tank is not just about choosing a diameter and height—it involves a detailed understanding of operational requirements, fluid properties, and structural constraints. Engineers must consider the following aspects:

1. Material Selection and Thickness

The choice of material impacts both structural integrity and chemical compatibility. Carbon steel is most common for petroleum storage, while stainless steel is used for corrosive chemicals or food-grade applications.

- Corrosion Allowance: Standard designs include an extra 3–6 mm of steel to account for long-term corrosion. This is critical in environments where moisture or chemical exposure is significant.

- Plate Thickness: Determined by the tank diameter, height, and internal pressure. Larger tanks require thicker walls to withstand hydrostatic pressure.

2. Tank Geometry

Cylindrical tanks dominate storage designs due to their structural efficiency and ease of construction. However, the following must be carefully analyzed:

- Diameter-to-Height Ratio: Common ratios range from 1:1 to 2:1. Tanks with high height-to-diameter ratios require stronger wall support.

- Roof Types:

- Fixed Roof: Simple and economical for low-vapor pressure liquids.

- Floating Roof: Reduces evaporation losses in volatile liquids like crude oil.

- External Floating Roof: Combines the advantages of fixed and floating designs.

3. Fluid Considerations

Different liquids exert different pressures, densities, and vapor characteristics, all affecting tank dimensions:

- Density: Heavier liquids require stronger wall supports and thicker plates.

- Temperature Effects: Expansion due to temperature changes can significantly affect volume and pressure inside the tank.

Real-World Applications

Case Study 1: Oil Storage Terminal

An oil terminal needs a storage tank capable of holding 20,000 barrels of crude oil. The engineering team chooses a cylindrical tank with a diameter of 60 ft. Based on historical operational constraints and environmental conditions, they implement the following:

- Wall Thickness: 0.5 in with a 0.125 in corrosion allowance.

- Roof Type: Internal floating roof to minimize evaporation losses.

- Foundation: Reinforced concrete ringwall foundation to support the heavy weight and distribute load evenly.

During design review, engineers simulate hydrostatic pressure distribution and wind load impacts. They verify that the tank can safely withstand extreme weather events up to 100 mph wind speeds and seismic activity rated at Zone 3.

Case Study 2: Chemical Plant Storage

A chemical manufacturing facility requires a storage tank for a corrosive liquid. Specifications:

- Capacity: 5,000 m³

- Material: Stainless steel grade 316L for chemical resistance.

- Roof: Fixed roof with vapor recovery system.

- Additional Design Features:

- Secondary containment with a bund wall to prevent environmental contamination.

- Corrosion sensors embedded in the tank walls for continuous monitoring.

The design prioritizes chemical compatibility, safety, and compliance with ISO 28300 standards for tank storage of hazardous liquids.

Common Standards and Compliance

Engineers rely on internationally recognized standards to guide tank dimensioning:

- API 650: Standard for welded steel tanks for oil storage. Provides specifications for plate thickness, material selection, and welding practices.

- ASME BPVC Section VIII: Pressure vessel design rules that sometimes apply to tanks operating under pressure.

- ISO 28300: Focused on the storage of dangerous chemicals with detailed containment and safety requirements.

Compliance ensures that tanks can withstand operational, environmental, and seismic loads safely while reducing the risk of leaks and structural failures.

Best Practices in Tank Dimensioning

- Optimizing Diameter and Height: Consider operational efficiency, maintenance access, and land availability. Taller tanks save space but require careful structural design.

- Load Distribution Analysis: Assess hydrostatic loads, wind, and seismic forces. Finite element analysis (FEA) is often used for large tanks.

- Maintenance and Inspection Planning: Adequate spacing for inspections, scaffolding, and potential retrofitting must be included.

- Safety Margins: Include design safety factors for extreme weather, accidental overfilling, and corrosion over the tank’s lifetime.

Practical Tips for Engineers

- Always consult the latest API 650 and ISO 28300 standards for updated design criteria.

- Integrate tank dimensioning software for rapid preliminary sizing, but validate manually for safety-critical applications.

- Factor in operational constraints such as pumping speed, filling rate, and vapor recovery systems.

- Plan for expansion joints or flexible connections if thermal expansion of the tank is significant.