In electrical engineering, understanding the relationship between AC motor speed (RPM) and frequency (Hz) is essential. IEC 60034-1 standards govern this relationship, providing guidelines for rotating machines, examples, and practical applications.

RPM to Frequency Conversion Calculator – IEC

How is frequency calculated from RPM?

What does the number of poles mean?

Table of Common RPM to Frequency Conversions

To facilitate quick reference, the following table presents common RPM values and their corresponding frequencies for standard AC motor configurations:

| RPM (Revolutions per Minute) | Frequency (Hz) |

|---|---|

| 3000 | 50 |

| 3600 | 60 |

| 1500 | 50 |

| 1800 | 60 |

| 1000 | 50 |

| 1200 | 60 |

| 750 | 50 |

| 900 | 60 |

These values correspond to synchronous speeds for motors with varying numbers of poles at standard supply frequencies.

Fundamental Formulas for RPM to Frequency Conversion

1. RPM to Frequency (Hz)

The basic formula to convert RPM to frequency is:

This formula is derived from the definition of frequency as the number of cycles per second. Since RPM measures revolutions per minute, dividing by 60 converts the time unit to seconds, yielding the frequency in Hertz.

2. Frequency to RPM

Conversely, to determine RPM from frequency:

This relationship is fundamental in designing and selecting motors for specific applications, ensuring compatibility with the power supply frequency.

Detailed Explanation of Variables

- RPM (Revolutions per Minute): Represents the mechanical speed of the motor shaft. It is influenced by factors such as the number of poles and the supply frequency.

- Frequency (Hz): Indicates the electrical supply frequency, typically 50 Hz or 60 Hz, depending on regional standards.

- Number of Poles: Refers to the number of magnetic poles in the motor. The number of poles directly affects the synchronous speed of the motor.

Real-World Examples and Applications

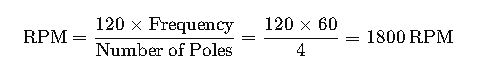

Example 1: Determining Synchronous Speed for a 4-Pole Motor

Given:

- Frequency = 60 Hz

- Number of Poles = 4

Using the formula:

This calculation indicates that a 4-pole motor operating at 60 Hz will have a synchronous speed of 1800 RPM.

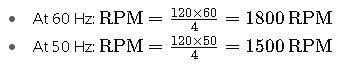

Example 2: Adjusting Motor Speed for Different Supply Frequencies

If a motor designed for 60 Hz operation is to be used in a region with a 50 Hz supply, the synchronous speed will change. For a 4-pole motor:

This reduction in speed can impact the motor’s performance and may require adjustments in the application.

IEC 60034-1 Standards and Their Impact

IEC 60034-1 outlines the performance and rating requirements for rotating electrical machines. It specifies the relationship between supply frequency, number of poles, and synchronous speed. Adhering to these standards ensures that motors operate efficiently and reliably across different regions and applications.

Practical Understanding of RPM to Frequency Conversion

In industrial settings, engineers often need to match motor speed with process requirements. The RPM to frequency relationship determines how fast a motor will rotate given a specific electrical supply frequency. Understanding this is essential for applications such as conveyor belts, pumps, compressors, and fans.

For example, in a manufacturing plant using a 50 Hz supply, a 4-pole motor will naturally run at 1500 RPM. If the process requires faster rotation, such as 1800 RPM, the supply frequency must be increased to 60 Hz or a different motor selected. This simple principle ensures that machines operate efficiently without risking mechanical failure.

Extended Table of Common RPM to Frequency Values

Below is a more extensive table covering common motor configurations and standard supply frequencies:

| Poles | Frequency (Hz) | Synchronous Speed (RPM) |

|---|---|---|

| 2 | 50 | 3000 |

| 2 | 60 | 3600 |

| 4 | 50 | 1500 |

| 4 | 60 | 1800 |

| 6 | 50 | 1000 |

| 6 | 60 | 1200 |

| 8 | 50 | 750 |

| 8 | 60 | 900 |

| 10 | 50 | 600 |

| 10 | 60 | 720 |

| 12 | 50 | 500 |

| 12 | 60 | 600 |

This table is widely used in motor selection charts to quickly estimate the expected speed based on supply conditions.

Real-World Applications

Example 1: Pump Speed Matching

A water treatment plant needs a pump running at 1500 RPM. The facility uses a 50 Hz supply. By checking the standard motor table, engineers confirm that a 4-pole motor will deliver the required speed without modifications. This avoids unnecessary costs and ensures optimal efficiency.

Example 2: Conveyor Belt Synchronization

A conveyor system in a packaging plant must run faster for high-speed operations. The original motor is rated for 1500 RPM at 50 Hz. By replacing it with a 4-pole, 60 Hz motor or adjusting the frequency with a variable frequency drive (VFD), the system can achieve 1800 RPM. This allows the conveyor to meet production demands without overloading the motor.

Practical Notes for Engineers

- Variable Frequency Drives (VFDs): Modern industrial systems often use VFDs to adjust frequency dynamically, controlling motor speed precisely without changing hardware.

- Motor Poles Selection: Fewer poles result in higher synchronous speed. Engineers must balance speed with torque requirements.

- Global Supply Considerations: Frequency varies by region (50 Hz in Europe, 60 Hz in North America). Motor selection must align with local supply standards.

- IEC Compliance: Ensuring motors comply with IEC 60034-1 guarantees efficiency, reliability, and global compatibility.