Electric motors power pumps, compressors, conveyors, and HVAC systems, making them indispensable in modern industrial automation worldwide. Their reliability depends on strict thermal management; operating temperature critically affects efficiency, insulation durability, safety, and overall motor lifespan.

Operating Temperature — Electric Motor Calculator (IEC / IEEE)

What does this calculator compute?

Key assumptions

Formulas used

Hot-spot temp = Average winding temp + Hot-spot allowance.

Allowable ambient for class = Tmax − ΔT − Hot-spot allowance.

Approx. insulation life multiplier ≈ 2^((Ref − Hotspot)/10) (Ref=100°C by default). This is a rule-of-thumb (life halves per +10°C).

Reference Tables for Operating Temperatures (IEC & IEEE)

The IEC 60034 and IEEE 841 standards specify common insulation classes, maximum permissible temperature rises, and ambient conditions for different motor types.

Table 1. Common Insulation Classes and Limits (IEC 60085, IEEE 117)

| Insulation Class | Max. Hotspot Temperature (°C) | Typical Temp Rise Limit (°C) | Margin to Ambient (40°C typical) | Typical Applications |

|---|---|---|---|---|

| Y | 90 | 45 | 5 | Small appliances, obsolete |

| A | 105 | 60 | 5 | Fans, light-duty motors |

| E | 120 | 75 | 5 | Early industrial motors |

| B | 130 | 80 | 10 | Standard induction motors |

| F | 155 | 105 | 10 | Pumps, compressors, HVAC |

| H | 180 | 125 | 15 | Traction, aerospace, heavy-duty |

| N | 200 | 140 | 20 | Specialized, high-reliability |

| R | 220 | 160 | 20 | Nuclear, aerospace |

Table 2. IEC vs IEEE Temperature Rise Measurement Methods

| Standard | Method | Reference Point | Common Applications |

|---|---|---|---|

| IEC 60034-1 | Resistance method (preferred), embedded sensors | Average winding temperature | General-purpose motors |

| IEEE 112 | Resistance method, thermocouples, RTDs | Hotspot or average temperature | Industrial-grade motors |

| IEC 60034-11 | Thermal protection curves | Thermal model of winding | Motors with electronic protection |

Table 3. Ambient Temperature and Derating Factors

| Ambient Temperature (°C) | Derating Factor (IEC/IEEE typical) | Notes |

|---|---|---|

| 30 | 1.05 | Better than standard 40°C |

| 40 | 1.00 | Standard reference |

| 45 | 0.96 | Reduced capability |

| 50 | 0.92 | Common in desert climates |

| 55 | 0.87 | Often requires Class H insulation |

| 60 | 0.82 | Special cooling needed |

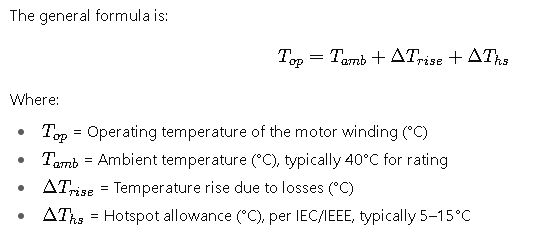

Core Formulas for Operating Temperature Calculations

Operating temperature in electric motors is determined by a combination of ambient temperature, temperature rise, and hotspot allowance.

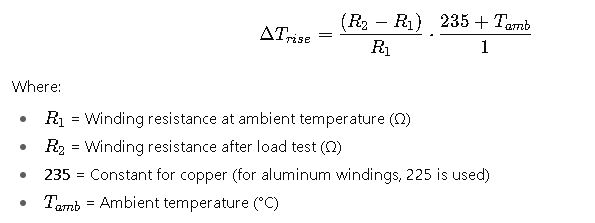

1. Temperature Rise by Resistance Method (IEC & IEEE)

The resistance method calculates average winding temperature:

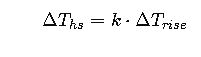

2. Hotspot Correction Factor (IEC 60034-1)

Where:

- k = Hotspot factor (typically 0.1–0.15 per IEC)

Example: For a winding rise of 80°C and k=0.1, hotspot = 8°C.

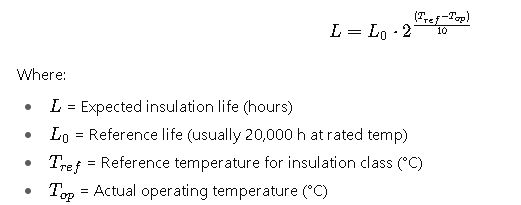

3. Insulation Lifetime Estimation (Arrhenius Model)

Thermal aging follows the Arrhenius exponential law:

This means every 10°C over the rated temperature halves insulation life.

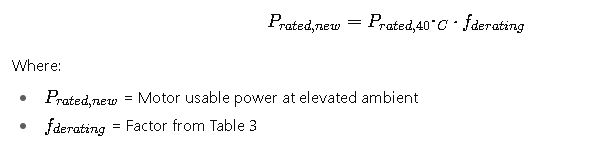

4. Derating Formula for Ambient Conditions

When ambient exceeds 40°C, derating is applied:

Real-World Application Examples of Operating Temperature in Electric Motors

Case Study 1: HVAC Centrifugal Pump Motor in a Tropical Climate

Background

A water treatment facility located in Southeast Asia operates several 200 kW, 4-pole induction motors driving centrifugal pumps. The site experiences average ambient temperatures of 45°C with peaks up to 50°C. Operators reported frequent tripping of thermal protection relays.

Analysis

- Ambient condition: At 45–50°C, the motors already operate above the IEC/IEEE standard reference of 40°C.

- Insulation class: Motors were designed with Class F (155°C) insulation, but operated near the limit due to insufficient cooling.

- Temperature rise: Measured winding rises averaged 105°C, which when added to 50°C ambient results in ~155°C, dangerously close to Class F maximum.

- Hotspot effect: Even a small 10°C hotspot pushed effective winding temperatures to 165°C.

Corrective Actions

- Installation of auxiliary cooling fans improved air circulation around the motor housing.

- Operators applied a derating factor of approximately 0.92 for 50°C operation, reducing mechanical load to ~184 kW.

- Motors were upgraded with Class H (180°C) insulation to extend life expectancy.

Outcome

- Reduced tripping events by 80%.

- Extended expected insulation life from ~18,000 hours to 45,000 hours.

- Verified compliance with IEC 60034-1 temperature rise limits under corrected operating conditions.

Case Study 2: IEEE-Compliant Industrial Compressor Motor in a Petrochemical Plant

Background

A petrochemical plant in Texas, USA, deployed IEEE 841 motors (premium severe-duty standard) for large compressors. Operating environments included high dust levels and fluctuating ambient temperatures between 35°C and 55°C.

Analysis

- Motor type: Severe-duty, totally enclosed fan-cooled (TEFC), Class B rise with Class F insulation.

- Operating issue: After two years, several motors exhibited winding resistance imbalance, indicating possible thermal hotspots.

- IEEE methodology: Thermocouples embedded in windings confirmed hotspot temperatures exceeding 160°C.

Corrective Actions

- Motors were retrofitted with RTD (Resistance Temperature Detector) sensors for continuous monitoring.

- Plant engineers recalibrated thermal overload protection based on IEEE 112 test standards rather than factory default.

- Ambient derating applied, and motors operated at 90% rated load during peak summer conditions.

Outcome

- Prevented unplanned shutdowns, saving approximately $500,000 annually in avoided downtime.

- Improved predictive maintenance through continuous monitoring of temperature trends.

- Ensured long-term compliance with IEEE 841 severe-duty thermal specifications.

IEC vs IEEE Approaches: Key Differences in Practice

Although both IEC and IEEE converge on similar temperature limits, there are important practical distinctions:

IEC (International Electrotechnical Commission)

- Global focus: Widely adopted in Europe, Asia, Africa, and Latin America.

- Ambient reference: Assumes 40°C as standard ambient.

- Temperature rise: Typically measured by the resistance method (average winding temperature).

- Hotspot allowance: Fixed value depending on insulation class (usually 5–15°C).

- Derating guidance: Explicit derating factors provided for high ambient conditions.

IEEE (Institute of Electrical and Electronics Engineers)

- Regional focus: More common in North America, especially for severe-duty motors.

- Test methods: Allows both resistance method and direct thermal measurement with thermocouples or RTDs.

- Hotspot consideration: Explicitly accounts for measured hotspots, not just average rise.

- Application orientation: Strong emphasis on industrial reliability (IEEE 841 motors for petrochemicals, refineries, etc.).

- Lifetime evaluation: Closer integration with Arrhenius thermal aging models for predictive maintenance.

Extended Insights for Engineers and Plant Managers

1. The Role of Insulation Class in Motor Selection

Choosing a motor with the right insulation class is not only about immediate compliance but also about future-proofing. For example, using Class H insulation in a plant where ambient may unexpectedly rise to 55°C ensures that motors survive unexpected load peaks and cooling failures.

2. Monitoring Technologies

Modern plants rarely rely only on nameplate data. Instead, they implement:

- Embedded RTDs in stator windings for real-time monitoring.

- Infrared thermography during predictive maintenance rounds.

- Smart motor sensors (e.g., ABB Ability™, Siemens MindSphere) that monitor temperature, vibration, and load simultaneously.

3. The Cost of Overheating

- Every 10°C increase beyond rated temperature halves insulation life.

- Overheating is responsible for 30–40% of motor failures globally.

- Rewinding costs typically represent 60–70% of a new motor price, while premature motor replacement can disrupt critical production.

4. Environmental and Energy Efficiency Impacts

- Motors running hotter than design are also less efficient, wasting energy as excess heat.

- Compliance with IEC and IEEE thermal guidelines directly contributes to energy savings and lower greenhouse gas emissions.

- High-efficiency motors (IE3/IE4) designed with optimized cooling channels can reduce thermal stress while lowering operating costs.