The design of electrical conduit systems is crucial for safety, efficiency, reliability, and long-term performance. The NEC defines strict requirements, with maximum conduit bends ensuring compliance, pullability, durability, and effective inspection processes.

Maximum Number of Bends Allowed in Conduit Runs — NEC Calculator

Calculate total bend degrees in a conduit run, remaining allowable degrees (NEC standard: 360°), and whether a pull box is required.

What does NEC say about maximum bends in a conduit run?

How is the calculator working?

When is a pull box required?

Formulas used

NEC Requirements for Maximum Conduit Bends

According to NEC Article 358.26 (for EMT), and similar sections for other raceways, the total number of bends in any conduit run between pull points (such as junction boxes or conduit bodies) shall not exceed 360 degrees. This rule applies regardless of conduit type (EMT, RMC, PVC, FMC, IMC, etc.).

This restriction ensures that conductors can be safely pulled without excessive stress, which might damage insulation or make future maintenance impossible.

Key points:

- Maximum total bend = 360° per run between pull points.

- Pull points include junction boxes, conduit bodies, or other accessible enclosures.

- Applies to all recognized conduit types under NEC.

- Exceeding this limit requires the installation of an additional pull box or conduit body.

Common Bend Configurations

Electricians typically use bends of 90°, 45°, 30°, and 22.5° depending on the installation constraints. By combining these standard angles, runs are constructed to fit architectural layouts while maintaining NEC compliance.

Below is a comprehensive table of common bend combinations and whether they comply with NEC’s 360° maximum requirement.

Table 1. Common Bend Combinations and NEC Compliance

| Bend Combination | Total Degrees | NEC Compliance (≤ 360°) |

|---|---|---|

| 4 × 90° bends | 360° | ✅ Allowed (limit reached) |

| 3 × 90° bends | 270° | ✅ Allowed |

| 2 × 90° + 2 × 45° | 270° | ✅ Allowed |

| 2 × 90° + 1 × 45° + 2 × 22.5° | 270° | ✅ Allowed |

| 1 × 90° + 6 × 45° | 360° | ✅ Allowed (limit reached) |

| 8 × 45° bends | 360° | ✅ Allowed (limit reached) |

| 16 × 22.5° bends | 360° | ✅ Allowed (limit reached) |

| 10 × 30° bends | 300° | ✅ Allowed |

| 12 × 30° bends | 360° | ✅ Allowed (limit reached) |

| 2 × 90° + 4 × 30° | 300° | ✅ Allowed |

| 2 × 90° + 1 × 45° + 1 × 30° | 255° | ✅ Allowed |

| 3 × 90° + 1 × 45° | 315° | ✅ Allowed |

| 3 × 90° + 2 × 30° | 330° | ✅ Allowed |

| 3 × 90° + 1 × 30° + 1 × 22.5° | 322.5° | ✅ Allowed |

| 4 × 90° + 1 × 22.5° | 382.5° | ❌ Not allowed |

| 5 × 90° bends | 450° | ❌ Not allowed |

| 2 × 90° + 3 × 45° + 1 × 30° | 345° | ✅ Allowed |

| 2 × 90° + 3 × 45° + 2 × 22.5° | 390° | ❌ Not allowed |

| 2 × 180° back-to-back bends | 360° | ✅ Allowed (limit reached, but practical issues exist) |

Table 2. Practical Examples of Bend Applications by Conduit Type

| Conduit Type | Typical Application | Common Bend Angles | Notes |

|---|---|---|---|

| EMT (Electrical Metallic Tubing) | Commercial buildings, exposed runs | 90°, 45°, 30°, 22.5° | Easily bent with hand bender |

| RMC (Rigid Metal Conduit) | Industrial settings, mechanical protection | 90°, 45° | Heavy-duty, usually factory bent |

| IMC (Intermediate Metal Conduit) | Similar to RMC but lighter | 90°, 45°, 30° | Requires special tools |

| PVC Conduit | Underground installations | 90°, 45°, 22.5° | Heat bending common |

| FMC (Flexible Metal Conduit) | Short connections, equipment whips | Various (custom) | More flexible, but still subject to NEC bend limits |

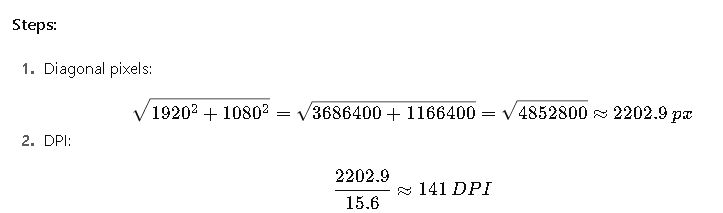

Formula for Maximum Conduit Bends

The NEC rule can be expressed mathematically as:

Detailed Explanation of Variables and Their Practical Implications

While the NEC defines the 360-degree rule as the governing requirement, real-world application requires understanding how each variable in conduit design affects performance, installation, and compliance. Below we break down the most relevant elements.

Bend Angles in Practice

- 90-degree bends: The most common type, used to make sharp turns or drops. They are essential for changing direction at walls, ceilings, or entering equipment. However, four of them will already reach the NEC limit.

- 45-degree bends: Useful for smoother directional changes and reducing pulling friction. Frequently combined with 90-degree bends to navigate complex layouts.

- 30-degree bends: Often applied in offset runs where a smaller angular correction is required.

- 22.5-degree bends: Typically used in segmented offsets, gradual transitions, or underground sweeps with PVC conduit.

Number of Bends

- Runs with fewer bends allow easier conductor pulling, reducing damage risk.

- Runs approaching 360 degrees should be avoided unless absolutely necessary, because practical pulling stress increases even before the maximum is reached.

Conduit Type

- Metallic conduits (EMT, RMC, IMC): Strong but less forgiving; bend limitations are stricter in practice due to conductor friction.

- Non-metallic conduits (PVC): Can be heat-bent into smooth sweeps, but still subject to the same NEC 360° limit.

- Flexible conduits (FMC, LFMC): Naturally adaptable, yet NEC still applies the same angular restrictions.

Pull Points and Accessibility

Pull boxes, conduit bodies (LBs, T-fittings, C-fittings), and junction boxes are critical for breaking long conduit runs.

- Every added pull point resets the bend count to zero from that location onward.

- Accessibility: NEC requires all pull points to remain accessible after installation. Concealed or buried pull points are not acceptable unless specifically designed for access.

Extended Table of Bend Scenarios

To improve usability, here is a comprehensive field reference of practical scenarios showing whether a given layout would be acceptable or not.

Table 3. Extended Scenarios for NEC Conduit Bend Compliance

| Scenario Description | Bend Breakdown | Total Degrees | NEC Compliance |

|---|---|---|---|

| Long hallway run with 4 corner turns | 4 × 90° | 360° | ✅ Allowed (at limit) |

| Drop from ceiling to panelboard, offset around beam | 2 × 90° + 2 × 45° | 270° | ✅ Allowed |

| Underground PVC sweep across driveway | 4 × 45° + 4 × 22.5° | 270° | ✅ Allowed |

| Vertical riser with back-to-back 90s into switchgear | 2 × 90° | 180° | ✅ Allowed |

| Industrial run around machinery footprint | 6 × 45° + 1 × 30° | 300° | ✅ Allowed |

| Tight mechanical room requiring multiple offsets | 3 × 90° + 2 × 45° | 315° | ✅ Allowed |

| Conduit passing across multiple elevation changes | 12 × 30° | 360° | ✅ Allowed (at limit) |

| Attempting 5 sharp corners with 90° each | 5 × 90° | 450° | ❌ Not allowed |

| Complex retrofit in old facility with 3 × 90° + 2 × 30° + 2 × 22.5° | 367.5° | ❌ Not allowed | |

| Outdoor service riser with gradual sweep | 8 × 22.5° | 180° | ✅ Allowed |

This extended table serves as a quick jobsite reference, preventing errors during layout planning.

Practical Design Considerations Beyond NEC

Even when staying within the 360-degree limit, engineers and electricians must account for pulling tension, conductor insulation integrity, and mechanical constraints.

Conductor Pulling Forces

The more bends in a run, the greater the pulling friction. While 360° is the maximum allowed, practical best practice suggests limiting to 270° or less in most applications, especially with larger conductors (e.g., 500 kcmil or above).

Box Fill and Conduit Fill

- Box fill: Additional pull boxes inserted to reset the bend count must still comply with box fill rules (NEC Article 314).

- Conduit fill: The more conductors present, the harder the pulling effort across multiple bends, even within NEC limits.

Equipment Accessibility

- Pull points must remain readily accessible for maintenance and future wiring.

- Runs designed with minimal bends simplify both installation and later troubleshooting.

Installation Methods

- Factory-swept elbows are preferred for long radius bends in underground PVC runs.

- Segmented bends (using smaller angles like 22.5°) reduce friction but consume available bend capacity quickly.

- Conduit bodies (LBs, LLs, LR fittings) are often used strategically to introduce accessible pull points in tight layouts.

Real-World Examples

Example 1: Commercial Office Conduit Run

Scenario: An office building requires an EMT conduit run from a distribution panel in the electrical room to a lighting control cabinet across the hall.

- Layout requires navigating three corners and a vertical drop.

- Proposed bends: 3 × 90° + 1 × 45°.

- Total = 315°.

Analysis:

- NEC limit of 360° is not exceeded.

- This run is compliant.

- However, pulling THHN conductors across 315° is still physically demanding.

- Best practice: Add a conduit body after the second 90° to split the run and simplify pulling.

Outcome: Installation approved and optimized by introducing a pull point, reducing field labor time.

Example 2: Industrial Plant Retrofit

Scenario: In an industrial facility, a rigid metal conduit (RMC) run must connect a motor control center (MCC) to a pump located 200 feet away. The route must bypass existing equipment, piping, and structural columns.

- Proposed bends: 4 × 90° + 1 × 30°.

- Total = 390°.

Analysis:

- This exceeds the NEC maximum of 360°.

- Inspectors will not approve the installation.

- A pull box must be introduced between the second and third 90° bends.

Outcome: With the added pull box, each run section now complies (two separate conduit runs: 180° + 210°). Conductors can be pulled with standard equipment, and NEC compliance is achieved.

Best Practices for Field Compliance

- Pre-plan conduit routes on drawings before installation to verify bend totals.

- Use long-radius factory elbows for large conductors to reduce stress.

- Insert pull points proactively if layouts exceed 270°, even if under 360°.

- Train field electricians to calculate bend totals during installation.

- Leverage conduit bodies strategically in tight spaces.

- Always verify accessibility of any added pull box or conduit body.

References and Authoritative Sources

For deeper study and authoritative information, consult the following references:

- NFPA – National Electrical Code (NEC) 2023 Edition

- NEMA – National Electrical Manufacturers Association

- IEEE Standards Association

- UL Standards for Conduit and Fittings

These resources ensure alignment with the latest safety standards, compliance practices, and engineering recommendations.