In electrical engineering, determining cables’ maximum current-carrying capacity is essential for safety, efficiency, and reliability. This guide explores methodologies and standards, including IEEE 835 and IEC 60287, for cable ampacity.

Maximum Current Calculator for Electrical Cables

Ampacity Tables: An Overview

IEEE 835 Standard

The IEEE 835-1994 Standard Power Cable Ampacity Tables provide over 3,000 ampacity values for extruded dielectric power cables rated up to 138 kV and laminar dielectric power cables rated up to 500 kV. These tables are based on typical cable constructions and operating conditions. They offer a practical reference for engineers during the design and installation phases.

IEC 60287 Standard

IEC 60287 outlines methods for calculating the current-carrying capacity of cables under steady-state conditions. It considers factors such as conductor resistance, ambient temperature, and thermal resistivity of surrounding materials. This standard is widely used for more precise and customized ampacity calculations.

Key Formulas for Ampacity Calculations

1. IEC 60287 Formula

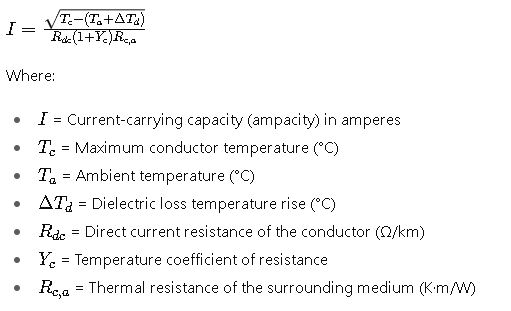

The basic formula for calculating the permissible current rating of a cable is:

2. Neher–McGrath Method

The Neher–McGrath method is an analytical approach used to estimate the steady-state temperature of electrical power cables. It involves solving a set of equations that account for heat generation, dissipation, and ambient conditions. This method is particularly useful for complex cable configurations and installations.

Real-World Application Examples

Example 1: Underground Cable Installation

Scenario: An underground 11 kV cable system is being designed for a commercial complex.

Solution:

- Determine Cable Specifications: Select a cable with appropriate voltage rating and conductor size.

- Calculate Ambient Temperature: Assess the average soil temperature at the installation depth.

- Apply IEC 60287 Formula: Use the formula to calculate the permissible current rating, considering factors like soil thermal resistivity and cable grouping.

- Adjust for Derating Factors: Apply correction factors for depth of burial and cable grouping to ensure safe operation.

Example 2: Overhead Transmission Line

Scenario: Designing an overhead 138 kV transmission line.

Solution:

- Select Conductor Type: Choose a conductor material (e.g., ACSR) with known properties.

- Assess Ambient Conditions: Consider factors like wind speed and ambient temperature.

- Use IEEE 835 Tables: Refer to the standard tables for initial ampacity estimates.

- Apply Neher–McGrath Method: For more accuracy, apply the method to account for specific installation conditions.

Maximum Current Tables for Electrical Cables

Determining the maximum current a cable can safely carry is crucial for electrical system design. Ampacity depends on conductor material, insulation type, installation method, ambient temperature, and grouping of cables. Below is an extensive table of common cables used in industrial and residential applications, reflecting typical maximum current values.Typical Maximum Current Tables (Ampacity)

| Conductor Size (AWG / mm²) | Insulation Type | Single-Core (A) | Multi-Core (A) | Buried Directly (A) | Conduit / Tray (A) |

|---|---|---|---|---|---|

| 1.5 mm² | PVC | 18 | 15 | 14 | 16 |

| 2.5 mm² | PVC | 24 | 21 | 20 | 22 |

| 4 mm² | PVC | 32 | 28 | 26 | 30 |

| 6 mm² | PVC | 41 | 36 | 33 | 38 |

| 10 mm² | PVC | 57 | 50 | 45 | 52 |

| 16 mm² | PVC | 76 | 66 | 60 | 69 |

| 25 mm² | PVC | 101 | 88 | 80 | 92 |

| 35 mm² | PVC | 125 | 109 | 98 | 114 |

| 50 mm² | PVC | 153 | 134 | 120 | 139 |

| 70 mm² | PVC | 193 | 168 | 150 | 175 |

| 95 mm² | PVC | 234 | 204 | 180 | 212 |

| 120 mm² | PVC | 269 | 234 | 210 | 245 |

| 150 mm² | PVC | 303 | 263 | 235 | 276 |

| 185 mm² | PVC | 346 | 301 | 270 | 315 |

| 240 mm² | PVC | 404 | 350 | 315 | 370 |

Notes:

- Values are for copper conductors.

- Ambient temperature considered: 30°C.

- Corrections needed for higher ambient temperatures or grouping multiple cables.

Factors Affecting Maximum Current

1. Conductor Material

- Copper: Higher conductivity, less voltage drop, higher ampacity.

- Aluminum: Lower cost, lighter, but requires larger cross-section for same current.

2. Insulation Type

- PVC (Polyvinyl Chloride): Common, economical, rated up to 70°C.

- XLPE (Cross-Linked Polyethylene): Higher thermal stability, rated up to 90°C or 105°C.

3. Installation Method

- Direct Burial: Heat dissipation into soil; lower ambient temperature increases ampacity.

- Conduit or Tray: Less heat dissipation; derating factors applied for multiple cables together.

4. Ambient Temperature

- Ampacity decreases as ambient temperature increases.

- Correction factors: Typically 0.91 for 35°C, 0.82 for 40°C, 0.71 for 50°C.

Practical Examples

Example 1: Residential Building Wiring

Scenario: A 10 mm² PVC-insulated copper cable is used to supply a 5 kW air conditioning unit in a residential building.

- Nominal voltage: 230V

- Power requirement: 5 kW → Current = P/V ≈ 5000 / 230 ≈ 21.7 A

- From the table: 10 mm² PVC single-core cable ampacity = 57 A

- Result: The cable is safe, with a margin of over 2x.

Considerations:

- Cable is installed in conduit with other wires: derate to ~52 A.

- Still sufficient for 21.7 A load.

Example 2: Industrial Plant Feeder Cable

Scenario: Supplying a motor with 120 kW at 400V three-phase using XLPE-insulated copper cable.

- Current calculation: I = P / (√3 × V × PF)

Assuming PF = 0.85, I = 120,000 / (√3 × 400 × 0.85) ≈ 204 A - Select cable: 95 mm² PVC cable, single-core ampacity = 234 A

- Result: The cable handles the load safely.

- Grouping with 3 other feeders: apply derating factor 0.87 → Adjusted ampacity ≈ 204 A

- Perfect fit.

Additional Tips for Engineers

- Always check manufacturer datasheets for cable-specific ampacity.

- Use derating factors when ambient temperature is above 30°C or when multiple cables are grouped.

- Consider future expansion: selecting a cable slightly higher than immediate needs avoids costly replacements.

- Ensure compliance with local regulations: NEC (US), IEC (Europe), or regional electrical codes.

- Document installation conditions, including conduit type, ambient temperature, and grouping, to maintain safety.