kW to BHP Converter

Extensive Conversion Table from kW to BHP

Below is a detailed table showing common kilowatt (kW) values and their equivalent in brake horsepower (BHP). The standard conversion factor is 1 kW = 1.34102209 BHP.

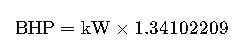

Formula Used:

| Power (kW) | Brake Horsepower (BHP) | Power (kW) | Brake Horsepower (BHP) |

|---|---|---|---|

| 0.5 | 0.6705 | 15 | 20.1153 |

| 1 | 1.3410 | 20 | 26.8204 |

| 2 | 2.6820 | 25 | 33.5255 |

| 3 | 4.0231 | 30 | 40.2307 |

| 4 | 5.3641 | 40 | 53.6409 |

| 5 | 6.7051 | 50 | 67.0511 |

| 6 | 8.0461 | 60 | 80.4613 |

| 7.5 | 10.0577 | 75 | 100.5766 |

| 10 | 13.4102 | 100 | 134.1022 |

| 12.5 | 16.7628 | 125 | 167.6277 |

| 15 | 20.1153 | 150 | 201.1533 |

| 17.5 | 23.4679 | 175 | 234.6788 |

| 20 | 26.8204 | 200 | 268.2044 |

| 22.5 | 30.1730 | 225 | 301.7299 |

| 25 | 33.5255 | 250 | 335.2555 |

| 30 | 40.2307 | 300 | 402.3066 |

| 35 | 46.9358 | 350 | 469.3577 |

| 40 | 53.6409 | 400 | 536.4088 |

| 50 | 67.0511 | 500 | 670.5110 |

| 75 | 100.5766 | 750 | 1005.7665 |

| 100 | 134.1022 | 1000 | 1341.0220 |

These values are often used in:

- Engine sizing

- Diesel generator specifications

- Hydraulic pump system designs

- International compliance and motor export configuration

Detailed kW to BHP Conversion Formulas

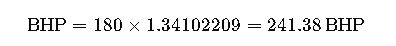

Primary Formula

Where:

- BHP = Brake Horsepower (imperial unit)

- kW = Kilowatts (metric unit of power)

- 1.34102209 = Exact conversion factor (based on mechanical horsepower: 1 HP = 745.699872 W)

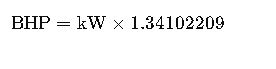

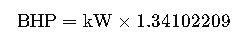

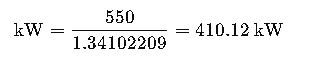

Reverse Formula (BHP to kW)

Explanation of Variables

| Variable | Description | Typical Values | Unit |

|---|---|---|---|

| kW | Power in kilowatts | 0.5 – 2000+ | kW (kilowatts) |

| BHP | Brake horsepower | 1 – 2700+ | BHP |

| 1.341 | Conversion constant | Fixed | – |

This conversion is especially important when using:

- IEC standards (kW) vs SAE/J1349 (BHP)

- Sizing motors for pumps, compressors, fans

- Matching power output for imported machinery

For reference:

- IEC 60034 defines standardized power ratings in kW

- SAE J1349 standardizes BHP at specific RPM and conditions

Real-World Application Examples

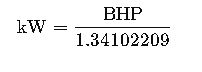

Example 1: Automotive Engine Selection

Scenario: A performance vehicle manufacturer in Germany needs to export a sports car to the U.S. where engine power is traditionally marketed in BHP. The engine in the vehicle is rated at 250 kW.

Solution:

Interpretation:

The car manufacturer can now market the vehicle as having ~335 BHP, aligning with U.S. consumer expectations and labeling standards.

Example 2: Diesel Generator Sizing for a Factory

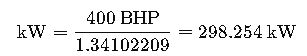

Scenario: A Colombian factory needs a backup diesel generator rated for 400 BHP. The local supplier provides power ratings in kW, and needs to find the minimum kW rating required.

Solution:

Interpretation:

The supplier should provide a generator rated for at least 300 kW to safely meet the power requirement of 400 BHP.

Why This Conversion Matters in Engineering

Engineering Standards and Compatibility

Different regions and industries use different units:

- Europe, Asia: Kilowatts (kW) per IEC 60034, ISO 3046

- United States, UK (legacy systems): BHP per SAE J1349, BS 649

Understanding and converting between these units is critical when:

- Exporting motors or engines

- Importing industrial equipment

- Comparing international datasheets

Use in Motors and Generators

In electric motors:

- Nameplates typically use kW

- Older or U.S.-marketed motors may use HP/BHP

- Equipment sizing, cable sizing, and protection settings may depend on accurate unit translation

In engine generators:

- Ratings often show prime power (kW) and standby power (BHP)

- Misinterpreting units can result in oversizing (higher cost) or undersizing (failure)

Conversion Between kW, BHP, and HP

It’s important to distinguish between mechanical horsepower (HP or BHP) and metric horsepower (PS or CV). The relationships are:

| Power Unit | Equivalent in kW | Notes |

|---|---|---|

| 1 BHP (mechanical) | 0.7457 kW | Common in U.S. |

| 1 Metric HP (PS) | 0.7355 kW | Common in Europe |

| 1 Electrical HP | 0.746 kW | For electric motors |

| 1 kW | 1.341 BHP | Standard formula |

Always verify the standard used in documentation:

- SAE J1349 = Brake HP (U.S.)

- DIN 70020 = Metric HP (Europe)

Online Tools and External References

For automated calculations and official references, consult the following:

- NIST – Power Conversion Factors

- SAE International

- International Electrotechnical Commission (IEC)

- Conversion Calculator: kW ↔ BHP

Summary of Key Points

- 1 kilowatt (kW) = 1.34102209 brake horsepower (BHP)

- Use the formula:

- Conversion is vital in international machinery trade, motor sizing, and generator specification

- Always check the unit context (mechanical HP, metric HP, electrical HP)

- Real-world applications range from automotive engineering to industrial backup power systems

Dynamic Power Charts by RPM and Load (Advanced Engine Applications)

While 1 kW = 1.34102209 BHP provides a static conversion, in real-world engine applications—especially internal combustion engines—the output power in BHP varies dynamically with RPM (revolutions per minute). The torque–speed relationship is key here.

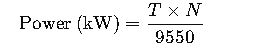

Formula for Power Based on Torque and RPM

Power (kW)=

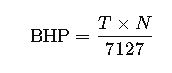

Or in BHP:

Where:

- T= Torque in Newton-meters (Nm)

- N= Rotational speed in revolutions per minute (RPM)

- 9550 = Constant derived from unit conversion for kW

- 7127 = Constant derived from unit conversion for BHP

This is vital for:

- Engine test bench evaluations

- Pump and fan sizing where speed fluctuates

- Understanding maximum vs continuous BHP ratings

Table: Torque vs RPM vs Power Output

| Torque (Nm) | RPM | Power (kW) | Power (BHP) |

|---|---|---|---|

| 100 | 1500 | 15.71 | 21.06 |

| 150 | 1500 | 23.56 | 31.60 |

| 200 | 1500 | 31.42 | 42.13 |

| 250 | 1500 | 39.27 | 52.66 |

| 200 | 1800 | 37.70 | 50.58 |

| 250 | 1800 | 47.13 | 63.23 |

| 300 | 1800 | 56.55 | 75.87 |

| 300 | 2100 | 65.98 | 88.52 |

This type of conversion is vital for tuning and real-time monitoring of rotating equipment, especially in automotive dyno testing and heavy-duty engine management.

Industry-Specific Standards and Use Cases

1. Automotive Sector

- Engines are often rated in BHP (per SAE J1349) for consumer-friendly figures.

- In Europe, manufacturers report kW (per EU regulation 715/2007).

- High-performance vehicles may show both for marketing and compliance.

Example: A Porsche 911 Carrera may be rated at:

- 283 kW (manufacturer spec)

- 380 BHP (advertised in U.S. market)

2. Electric Motors and Drives

- IEC 60034 specifies kW for electric motor nameplates.

- However, many old standards and suppliers (especially in the U.S.) still refer to HP/BHP.

Conversion Tip: For three-phase motors, the actual kW must also consider power factor and efficiency for real applications.

3. Diesel and Gas Generators

- Power is given in kW (electrical) or BHP (mechanical) depending on the application.

- Always differentiate prime, continuous, and standby ratings.

| Rating Type | kW Definition | BHP Context |

|---|---|---|

| Prime | Continuous variable load | Sized for average BHP |

| Standby | Emergency use only | Sized for max BHP |

| Continuous | Constant full load | Sized equal to nameplate BHP |

Real-World Example 3: Industrial Pump Driven by Engine

Scenario: A mining company is selecting an engine to drive a slurry pump requiring 180 kW mechanical input. The supplier provides engines rated in BHP only.

Solution:

Interpretation: The client must select an engine with at least 242 BHP to meet the load without overloading the engine.

Considerations:

- Add 10–15% margin for losses and startup torque.

- Ensure cooling systems and transmission are matched to BHP.

Real-World Example 4: Compliance with Marine Diesel Regulations

Scenario: A shipping company must certify an onboard auxiliary diesel engine’s power rating for environmental emission limits. IMO MARPOL Annex VI requires reporting in kW, but the engine datasheet lists BHP only.

Engine rated: 550 BHP

Required: kW rating for certification

Outcome:

- The company documents 410 kW on the IMO engine certificate.

- Complies with EU and International Maritime Organization (IMO) reporting formats.

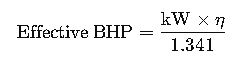

Power Losses and Efficiency Considerations

In many applications, simply converting from kW to BHP is not sufficient. Losses due to transmission, friction, and efficiency need to be factored in.

Effective BHP with Efficiency:

Where:

- η= Efficiency (0–1)

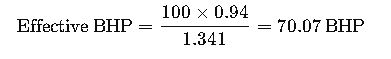

Example:

- A 100 kW electric motor at 94% efficiency:

This is critical in:

- Sizing drives

- Matching gearbox loads

- Avoiding underpowered configurations

Typical Engine and Motor Ratings (kW ↔ BHP)

| Equipment Type | Typical kW Range | Approx BHP Range |

|---|---|---|

| Small car engine | 50–100 kW | 67–134 BHP |

| Truck diesel engine | 150–400 kW | 201–536 BHP |

| Industrial motor | 5–200 kW | 6.7–268 BHP |

| Backup generator | 100–1000 kW | 134–1340 BHP |

| Marine propulsion | 500–5000 kW | 670–6700 BHP |

Common Mistakes and How to Avoid Them

- Mixing metric and imperial units without proper conversion

- Confusing BHP with metric HP (often leads to 1.36 multiplier instead of 1.341)

- Neglecting losses in mechanical systems

- Rounding excessively, resulting in power mismatch

- Not considering environmental conditions affecting rated output (e.g., ISO 3046, SAE J1995)

Final Recommendations for Engineers and Designers

✅ Always use 1.34102209 for precise conversion

✅ Check whether BHP or metric HP is used in documentation

✅ Validate actual power delivery using torque and RPM where applicable

✅ Include safety factors and system losses when sizing

✅ Use authoritative references and standards (IEC, SAE, ISO)