Concrete compressive strength, f’c, is a critical property determining concrete structures’ safety and overall performance. It represents the compressive stress causing failure in a specimen, typically measured after twenty-eight days.

Concrete Strength Calculator (f’c)

What is f’c?

Formula used

f’c = k1·C/(W/A) + k2·Admixture

where C = cement, W = water, A = aggregate, k1 and k2 are constants.

Why might it differ from real strength?

1. Common Concrete Strength Values (f’c)

Concrete strength classes are standardized to ensure consistency and reliability in construction. The most widely used classification systems include the European Standard EN 206 and the American Concrete Institute (ACI) standards.

1.1 European Standard EN 206

In the European context, concrete is classified based on its characteristic compressive strength at 28 days, denoted as f’c. The strength classes are represented as Cxx/yy, where ‘xx’ is the characteristic strength in MPa, and ‘yy’ is the characteristic cube strength in MPa.

| Strength Class | f’c (MPa) | f’c,cube (MPa) |

|---|---|---|

| C25/30 | 25 | 30 |

| C30/37 | 30 | 37 |

| C35/45 | 35 | 45 |

| C40/50 | 40 | 50 |

| C45/55 | 45 | 55 |

| C50/60 | 50 | 60 |

1.2 American Concrete Institute (ACI) Standards

In the United States, concrete strength is often specified in pounds per square inch (psi). The ACI provides guidelines for determining the required average compressive strength (f’cr) based on the specified design strength (f’c) and the standard deviation (s) of the concrete mix.

| f’c (psi) | f’cr (psi) |

|---|---|

| ≤ 3,000 | f’c + 1,000 |

| 3,000–5,000 | f’c + 1,200 |

| > 5,000 | 1.10 × f’c + 700 |

Note: The standard deviation (s) is determined based on historical data or trial mixes and influences the required average strength.

2. Formulas for Concrete Strength Calculation

Understanding the formulas used to calculate f’c is crucial for accurate mix design and quality control.

2.1 Basic Compressive Strength Formula

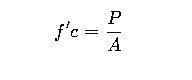

The compressive strength (f’c) is calculated using the formula:

Where:

- P= Maximum load applied to the specimen (in Newtons)

- A = Cross-sectional area of the specimen (in mm²)

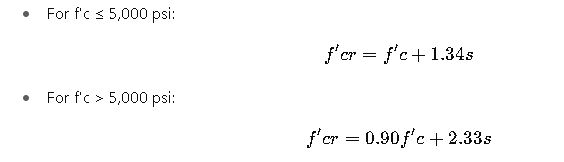

2.2 Required Average Strength (f’cr)

To account for variability in concrete strength, the ACI provides equations to determine the required average compressive strength:

Where:

- s= Standard deviation of the compressive strength (in psi)

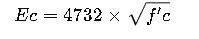

2.3 Modulus of Elasticity (Ec)

The modulus of elasticity is an important property that relates to the stiffness of concrete:

Where:

- Ec= Modulus of elasticity (in psi)

- f′c= Compressive strength (in psi)

Note: This formula is applicable for normal-weight concrete.

3. Real-World Examples of Concrete Strength Calculation

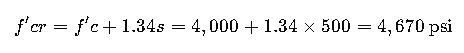

3.1 Example 1: Residential Building Slab

A residential building requires a concrete slab with a specified compressive strength (f’c) of 4,000 psi. Historical data indicates a standard deviation (s) of 500 psi.

- Using the ACI formula for f’c ≤ 5,000 psi:

Result: The required average compressive strength for the mix design is 4,670 psi.

3.2 Example 2: High-Rise Building Columns

For a high-rise building, concrete columns require a specified compressive strength (f’c) of 6,000 psi. The standard deviation (s) is determined to be 600 psi.

- Using the ACI formula for f’c > 5,000 psi:

Result: The required average compressive strength for the mix design is 6,798 psi.

4. Additional Considerations in Concrete Strength Calculation

4.1 Influence of Water-Cement Ratio

The water-cement (w/c) ratio is a critical factor influencing concrete strength. A lower w/c ratio generally leads to higher strength and durability.

4.2 Effect of Curing Conditions

Proper curing ensures that the concrete achieves its intended strength. Inadequate curing can result in lower strength and increased permeability.

4.3 Impact of Aggregate Quality

The type, size, and grading of aggregates affect the workability and strength of concrete. Well-graded aggregates contribute to better packing and reduced voids.

4.4 Role of Admixtures

Admixtures such as plasticizers, retarders, and accelerators can modify the properties of concrete, allowing for adjustments in mix design to achieve desired strength and workability.

5. Conclusion

Accurate calculation of concrete compressive strength is essential for the design and construction of safe and durable structures. By understanding and applying the appropriate formulas and considering factors such as standard deviation, water-cement ratio, curing conditions, aggregate quality, and admixtures, engineers can ensure that concrete mixes meet the required specifications and perform as intended.