Correct motor protection is vital to ensure safety and efficiency in any electrical system.

This article provides a detailed guide on motor protection circuit breakers, NEC guidelines, and calculator design.

Extensive Reference Table: Circuit Breaker Sizes for Motor Protection (Based on NEC 2023 Table 430.52)

The following table shows typical full-load current (FLC) values and corresponding maximum allowable circuit breaker sizes for motors based on NEC guidelines. The values depend on motor horsepower, voltage, phase, and type of circuit breaker (inverse time or instantaneous trip).

| Motor HP | Voltage | Phase | FLC (A) per NEC Table 430.248 | Inverse Time Breaker (Max 250%) | Instantaneous Trip Breaker (Max 800%) |

|---|---|---|---|---|---|

| 0.5 | 230 | 1 | 4.8 | 12 A | 38 A |

| 1 | 230 | 1 | 8.0 | 20 A | 65 A |

| 1.5 | 230 | 1 | 10.0 | 25 A | 80 A |

| 2 | 230 | 1 | 12.0 | 30 A | 96 A |

| 3 | 230 | 3 | 9.6 | 24 A | 77 A |

| 5 | 230 | 3 | 15.2 | 38 A | 122 A |

| 7.5 | 230 | 3 | 22.0 | 55 A | 176 A |

| 10 | 230 | 3 | 28.0 | 70 A | 224 A |

| 15 | 230 | 3 | 42.0 | 105 A | 336 A |

| 20 | 460 | 3 | 27.0 | 67.5 A | 216 A |

| 25 | 460 | 3 | 34.0 | 85 A | 272 A |

| 30 | 460 | 3 | 40.0 | 100 A | 320 A |

| 40 | 460 | 3 | 52.0 | 130 A | 416 A |

| 50 | 460 | 3 | 65.0 | 162 A | 520 A |

| 60 | 460 | 3 | 77.0 | 192 A | 616 A |

| 75 | 460 | 3 | 96.0 | 240 A | 768 A |

| 100 | 460 | 3 | 124.0 | 310 A | 992 A |

| 125 | 460 | 3 | 156.0 | 390 A | 1248 A |

| 150 | 460 | 3 | 180.0 | 450 A | 1440 A |

FLC values extracted from NEC Table 430.248 and Table 430.250.

NEC-Based Formulas for Motor Protection Breaker Sizing

Correct breaker sizing is governed by NEC Article 430, specifically Sections 430.52, 430.248, and 430.250. These sections prescribe multiplier percentages based on the motor type and breaker class.

1. Inverse Time Circuit Breaker

Formula:

Breaker Size (A) = FLC × 2.52. Instantaneous Trip Breaker

Formula:

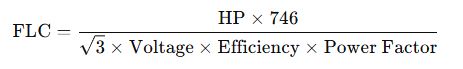

Breaker Size (A) = FLC × 8.03. FLC Determination

Formula (for 3-phase motors):

This formula is theoretical. NEC Table 430.250 should be used instead, as it provides standard FLC values for sizing.

Real-World Examples

Example 1: 15 HP, 3-phase, 230V motor, Inverse Time Breaker

- FLC = 42 A

- Breaker Sizing = 42 A × 2.5 = 105 A

Example 2: 25 HP, 3-phase, 460V motor, Instantaneous Trip Breaker

- FLC = 34 A

- Breaker Sizing = 34 A × 8.0 = 272 A

Example 3: 7.5 HP, 3-phase, 230V motor, Inverse Time Breaker

- FLC = 22 A

- Breaker Sizing = 22 × 2.5 = 55 A

Example 4: 50 HP, 3-phase, 460V motor, Instantaneous Trip Breaker

- FLC = 65 A

- Breaker Sizing = 65 × 8.0 = 520 A

FAQs – Frequently Asked Questions

Q1: Can I use the nameplate current instead of the NEC table?

A: No. Always use NEC tables for breaker sizing as nameplate current may not represent worst-case full-load conditions.

Q2: What if my calculated breaker size is not standard?

A: Use the next higher standard breaker size, but verify with NEC 240.6(A) and ensure it doesn’t exceed protection limits for the equipment.

Q3: Should I oversize the breaker to prevent nuisance tripping?

A: Only within NEC limits. Oversizing beyond code can compromise protection.

Q4: Can circuit breakers protect against overloads?

A: No. Circuit breakers protect against short circuits. Overloads must be handled by thermal protection devices.

Q5: Do VFDs change how I size the breaker?

A: Yes. Use manufacturer guidelines, as VFDs often have different requirements and include internal protections.

Coordination with Controllers and Overload Protection

Proper coordination between the motor controller, circuit breaker, and overload protection is mandatory to avoid nuisance tripping and meet NEC Article 430.

- Overload protection: Set between 115%-125% of FLC per NEC 430.32

- Short-circuit protection: Provided by breaker; must not exceed NEC 430.52

- Controllers: Starters and contactors must be rated for motor load

Curves and Trip Types

Circuit breakers may have different trip characteristics:

- Type B: Trips between 3–5× rated current (residential, light loads)

- Type C: Trips between 5–10× (motors with moderate inrush)

- Type D: Trips between 10–20× (motors with high inrush, transformers)

Best Practices and Mistakes to Avoid

- Do use NEC tables for consistency

- Do check coordination with overload and conductors

- Don’t undersize breaker to “protect” the motor

- Don’t use general-purpose breakers for high-inrush motors

Related Standards and Resources

- NEC 2023 Handbook – NFPA

- NEMA MG1 (Motor and Generator standards)

- UL 508A / UL 508C (Industrial control panels and VFDs)

- IEC 60947-4-1 (International standard for motor controllers)

Conclusion

Accurate sizing of motor protection circuit breakers is essential for the safety and reliability of electrical systems. Following NEC guidelines ensures code compliance and protection of both equipment and personnel. Use this guide, table, and examples to confidently size breakers for motors in your installations.

Stay tuned for our interactive Motor Circuit Breaker Sizing Calculator, coming soon to help engineers automate NEC-compliant selections.