Precise capacitor selection ensures IEC motor reliability, efficiency, and compliance under variable load conditions today.

This guide provides calculator logic, formulas, standards references, and practical examples for engineers globally professionally.IEC Motor Capacitor Selection & Power-Factor Correction Calculator

Fundamentals of capacitor selection for IEC motors

Capacitors used with IEC motors perform three principal functions: produce phase shift for single-phase motors, provide starting torque with start capacitors, and compensate reactive power (power factor correction) for three-phase motors. Selection is driven by electrical requirements (voltage, frequency, current), mechanical requirements (starting torque, duty cycle), environmental parameters (temperature, humidity), and standards/compliance requirements (safety, endurance).Key technical terms:- Run capacitor: continuous-duty capacitor connected to provide a phase-shifted current for motor auxiliary winding.

- Start capacitor: high-capacitance device used briefly during motor starting to produce high starting torque; typically disconnected by centrifugal switch or relay.

- Reactive power (Q): measured in VAR (or kVAR), energy exchanged between source and reactive elements per unit time; for capacitors Q is capacitive (negative reactive).

- Power factor (PF): cos(φ) where φ is the current-voltage phase angle; PF improvement reduces line current for same real power.

- Equivalent motor inductance (L): the inductive component seen by capacitors; important for avoiding resonance.

Must-have calculator inputs and constraints

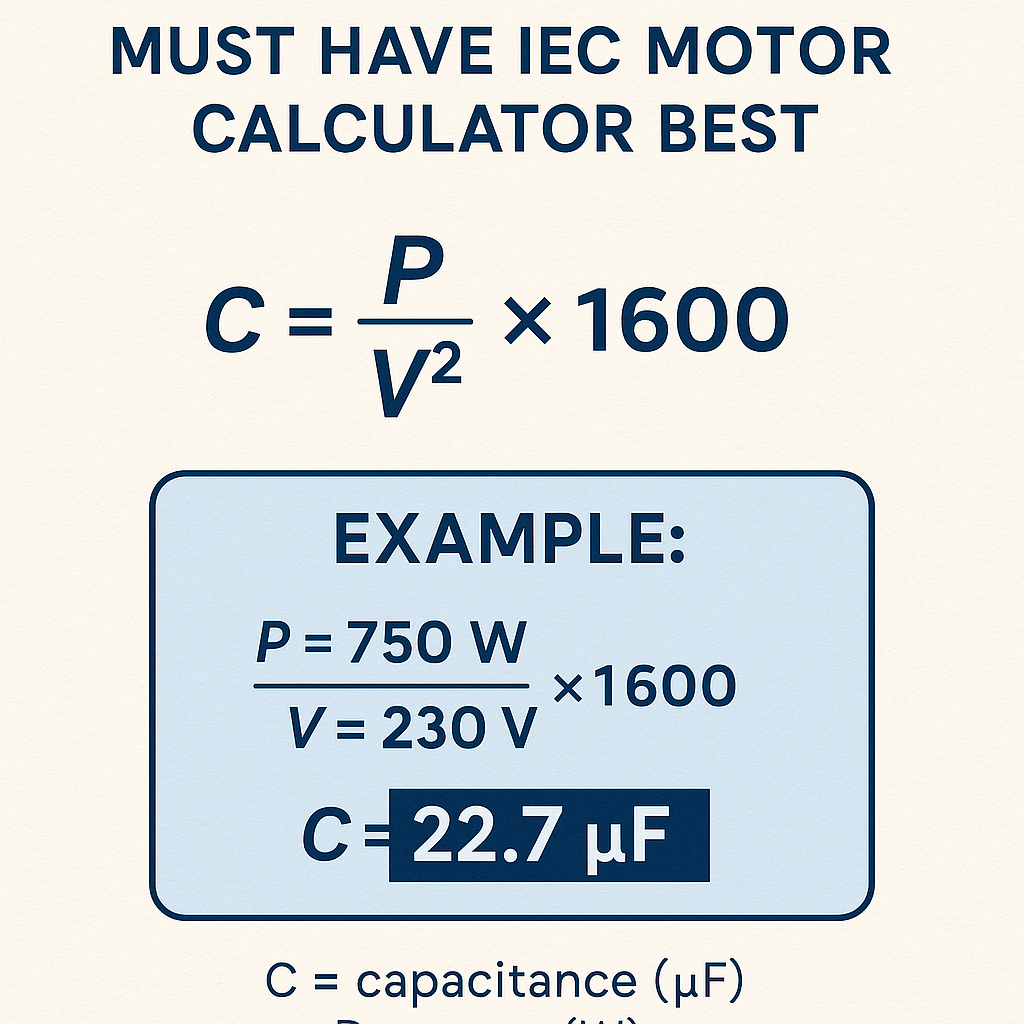

An IEC motor capacitor calculator intended for engineers should require:- Nameplate data: rated power (kW or HP), rated voltage, rated current, number of phases, rated frequency, and rated power factor.

- Target objective: start torque requirement, run phase-shift, or power factor target (for PFC).

- Connection: single-phase or three-phase (star/delta) and capacitor bank connection (delta/star).

- Duty cycle and time constraints: permitted continuous duty, intermittent start duty, ambient temperature, altitude.

- Harmonics and THD environment: presence of drives or non-linear loads affecting capacitor stress.

- Safety margins: tolerance, derating for temperature, life expectancy, and inrush capabilities.

Key formulas and variable explanations

Basic capacitor current and capacitance

C = I / (2 * pi * f * V)

- C — capacitance in farads (F). Typical presentation in microfarads (µF): 1 µF = 1e-6 F.

- I — desired reactive current (A) that the capacitor must supply.

- f — system frequency in hertz (Hz); typical 50 Hz or 60 Hz.

- V — RMS voltage across the capacitor (V). For three-phase delta-connected capacitor banks V is line-line voltage; for star-connected capacitor banks use line-neutral voltage (V_LN = V_LL / sqrt(3)).

Reactive power to capacitance relationship

C = Q / (V^2 * 2 * pi * f)

- Q — reactive power in VAR (or kVAR when using 1e3 factor). For three-phase total reactive power convert to per-phase Q_phase = Q_total / 3 when using per-phase formulas.

- V — RMS voltage across capacitor as above (use phase voltage matching connection).

- Factor 2 * pi * f is angular frequency (omega).

Power factor correction calculation

Required_kVAR = P_kW * (tan(phi1) - tan(phi2))

- P_kW — active power in kilowatts delivered to the motor (kW).

- phi1 — initial power factor angle: acos(initial PF).

- phi2 — target power factor angle: acos(target PF).

- tan() — tangent of respective angles.

Resonant frequency with motor inductance

f_res = 1 / (2 * pi * sqrt(L * C))

- f_res — resonance frequency in hertz. Avoid placing capacitor‑motor network resonance near system harmonic frequencies.

- L — equivalent motor inductance (H) seen by capacitor; can be derived from synchronous reactance and line frequency or from locked-rotor reactance data.

- C — capacitance (F).

Typical values and units

- System frequency f: 50 Hz or 60 Hz.

- Voltages: 230 V (single-phase) and 400 V / 50 Hz or 480 V / 60 Hz (three-phase industrial supply).

- Capacitance ranges: single-phase run capacitors frequently 1 µF to 250 µF; three-phase PFC capacitors per phase commonly 5 µF to 500 µF depending on kVAR and voltage.

Selection flowchart for an IEC-compliant capacitor calculator

Required algorithm steps:- Read nameplate and desired objective (run/start/PFC).

- If PFC: compute Required_kVAR using starting PF and target PF, then compute per-phase Q and apply C = Q / (V^2 * 2 * pi * f).

- If run/start for single-phase: determine desired auxiliary current or µF per rated motor power using nameplate or manufacturer guidance; compute C = I / (2 * pi * f * V).

- Verify voltage rating of capacitor is ≥ system RMS voltage; apply safety margin (typically 1.15 × operating voltage for continuous duty, higher for surge-prone environments).

- Check resonance: calculate f_res and ensure it is sufficiently separated from dominant harmonic frequencies (e.g., avoid 5th, 7th harmonics and switching frequencies of drives).

- Adjust for temperature derating and harmonic content: increase capacitance or select higher ripple current rated components where required.

- Format final bill-of-materials: capacitor part numbers, voltage class (VAC), capacitance ± tolerance (±5%/±10%), enclosure type, and required switching/discharge devices.

Tables of common values

| Single-phase Motor Rating (kW) | Approx. HP | Typical Run Capacitor @230 V, 50 Hz (µF) | Typical Start Capacitor @230 V, 50 Hz (µF) |

|---|---|---|---|

| 0.18 | 0.25 | 3–8 | 30–80 |

| 0.37 | 0.5 | 6–12 | 40–120 |

| 0.55 | 0.75 | 10–18 | 60–150 |

| 0.75 | 1.0 | 15–30 | 80–180 |

| 1.1 | 1.5 | 25–50 | 100–220 |

| 1.5 | 2.0 | 40–80 | 150–300 |

| 2.2 | 3.0 | 60–110 | 200–400 |

| 3.0 | 4.0 | 90–160 | 300–600 |

| Three-phase Motor (kW) | Voltage (V) | Initial PF | Target PF | Total kVAR Required | Per-phase Capacitance (µF) — delta connection |

|---|---|---|---|---|---|

| 7.5 | 400 | 0.78 | 0.95 | 7.5 kVAR | ~50 µF |

| 15 | 400 | 0.8 | 0.95 | 14.5 kVAR | ~97 µF |

| 30 | 400 | 0.8 | 0.95 | 29.1 kVAR | ~195 µF |

| 55 | 400 | 0.8 | 0.95 | 53.6 kVAR | ~360 µF |

| 75 | 400 | 0.82 | 0.95 | 66.0 kVAR | ~443 µF |

Design considerations for IEC compliance and reliability

When selecting capacitors for IEC motors consider:- Standards: use capacitors specified and tested to IEC 60252-1 for motor-run capacitors and IEC 60831 for power capacitors. Verify dielectric type (metallized polypropylene) and rated life.

- Voltage rating and surge capability: choose rated voltage greater than system RMS, consider surge withstand (peak voltage 1.4×RMS for single-phase switching transients). Use IEC guidance on overvoltage categories and insulation class.

- Temperature derating: capacitor capacitance and life decline with temperature; apply derating curves and select units with higher temperature class if ambient exceeds 40°C.

- Ripple current and ESR: select parts with rated ripple current adequate for harmonic content; low ESR improves dissipation and life.

- Discharge resistor: motor-run capacitors should include a discharge resistor or external bleed to ensure safe residual voltage per safety norms.

- Switchgear: for PFC banks, use appropriate switching devices (contactors, vacuum switches) and inrush restriction to avoid capacitor switching overcurrent and nuisance tripping.

- Harmonic amplification and resonance risk: calculate network resonance with motor inductance and avoid placing f_res near dominant harmonic orders (commonly 5th and 7th for 50 Hz systems).

Example case studies with step-by-step solutions

Example 1 — Single-phase run capacitor sizing for a 1.1 kW, 230 V, 50 Hz motor

Given:- Motor rated power P = 1.1 kW

- Supply voltage V = 230 V (single-phase)

- System frequency f = 50 Hz

- Nameplate PF ~ 0.75 (assumed for selection)

- Objective: determine a run capacitor to provide auxiliary winding current approximately equal to main winding current at starting to achieve improved starting torque.

I_FL ≈ P / (V * PF) = 1100 W / (230 V * 0.75) = 1100 / 172.5 ≈ 6.38 A

Step 2 — decide desired reactive current for auxiliary winding; for PSC motors typical auxiliary current near main current yields good torque. Set I_cap ≈ 6 A (engineering choice based on manufacturer curves).Step 3 — compute capacitance:C = I / (2 * pi * f * V) = 6 / (2 * pi * 50 * 230)

C ≈ 6 / 72,256 ≈ 0.00008305 F = 83.05 µF

Example 2 — Three-phase power factor correction for a 55 kW motor

Given:- P = 55 kW

- System voltage V_LL = 400 V, frequency f = 50 Hz

- Initial PF1 = 0.80 lagging

- Target PF2 = 0.95

- Connection: delta capacitors (each sees 400 V)

phi1 = acos(0.80) = 36.87°, tan(phi1) ≈ 0.75

phi2 = acos(0.95) = 18.19°, tan(phi2) ≈ 0.329

Required_kVAR = P_kW * (tan(phi1) - tan(phi2)) = 55 * (0.75 - 0.329) = 55 * 0.421 = 23.155 kVAR

Step 3 — per-phase reactive power for delta:Q_phase = 23.155 kVAR / 3 = 7.718 kVAR = 7,718 VAR

C = Q_phase / (V^2 * 2 * pi * f)

C = 7,718 / 50,265,482 ≈ 0.00015355 F = 153.55 µF

Practical engineering tips and pitfalls

- Avoid oversizing start capacitors for continuous duty: start capacitors are not designed for continuous operation and will overheat quickly if left connected.

- Always derate capacitance for elevated ambient temperature and altitude (consult manufacturer derating curves).

- For power factor correction near large non-linear loads, consider detuned filters to prevent resonance and to handle harmonic currents; tune typically at 190–210 Hz (for 50 Hz systems) to avoid 5th harmonic amplification.

- Use step banks or switched capacitor sections to adapt to variable load conditions and to limit inrush stresses on switching devices.

- Follow IEC 60252-1 and IEC 60831 guidance for safety, marking, and life testing requirements.

Reference standards and authoritative links

- IEC 60252-1 — Capacitors for motor-run applications: general requirements and tests. Reference: https://www.iec.ch/ (search IEC 60252-1)

- IEC 60831 — Power capacitors for power factor correction: product specifications and testing. Reference: https://www.iec.ch/

- IEC 60034 — Rotating electrical machines (general requirements and nameplate data): https://www.iec.ch/

- NEMA MG1 — Motors and Generators standards and manufacturer recommendations: https://www.nema.org/

- ABB Application Notes — motors and capacitors installation guides (practical engineering resources): https://new.abb.com/

- Siemens Motors and Drives technical documentation: https://new.siemens.com/

- IEEE standards and papers on power factor correction and capacitor switching: https://standards.ieee.org/

Summary checklist for capacitor selection tool and best practices

- Inputs required: power (kW/HP), voltage, frequency, PF, motor type, desired objective (start/run/PFC), duty cycle, harmonic environment.

- Output: recommended capacitance values (µF), voltage rating, kVAR per phase, wiring connection, suggested part numbers, safety margins, and resonance warnings.

- Verification: cross-check with manufacturer catalog data and run a resonance analysis using measured or estimated motor inductance.

- Compliance: ensure components comply with IEC 60252-1 or IEC 60831 and local electrical codes, include required marking and safety devices.