Power generator startup involves quick calculations and efficient voltage drop estimations. Our guide explains the process simply and precisely.

Readers will learn thorough calculations, formulas, and real-life examples, ensuring seamless generator startup voltage drop analysis.

AI-powered calculator for Calculation of voltage drop during generator startup

Example Prompts

- Calculate 220V generator startup with 15 A inrush current.

- Determine voltage drop for 400V, 25 A startup across 30 m cable.

- Compute startup voltage drop for 120V generator, 10 A load, 20 m conductor.

- Estimate generator startup drop for 240V, 18 A current over 50 m line resistance.

Understanding Voltage Drop in Generator Startup

Voltage drop represents the loss in voltage as power flows through cables and internal impedances. It is critical during startup due to high transient currents.

Voltage drop calculation is essential because generator startup involves inrush currents that exceed normal operating levels, leading to significant voltage losses. Accurately estimating these drops not only improves system efficiency but also minimizes potential damage to connected equipment or the generator itself. In this detailed guide, we cover the theoretical backgrounds, the necessary formulas, and how each term in these formulas contributes to calculating voltage drop. You will also see extensive tables, clear examples, and expert recommendations, making this content a one-stop resource for engineers and technicians alike.

Fundamental Concepts Behind Voltage Drop

During startup, generators experience an inrush current, much larger than the normal operating current. This surge is a result of magnetizing the generator’s components and charging filters or capacitors.

When generators transition from off to on, internal impedance—including both resistive and reactive components—plays a crucial role in determining the amount of voltage drop experienced across all conductive elements. The calculation considers the load connected to the generator and the inherent properties of cables, connectors, and even the generator’s winding configurations. Using fundamental principles like Ohm’s Law and Kirchhoff’s Voltage Law, we build detailed quantifications and predictions.

Theoretical Background and Key Equations

Voltage drop is calculated based on the total impedance in the circuit and the current flowing through it. The primary equation is derived from Ohm’s Law.

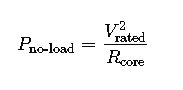

One of the core equations is:

- I_start: The startup inrush current (in amperes, A). Inrush currents can be several times the rated current.

- R_total: The total effective resistance (or impedance) including cable resistance, internal generator resistance, and connection resistances (in ohms, Ω).

During AC calculations and when reactive components are significant, the formula may extend to include reactance. Thus, a more generalized formula is:

- X: Represents the reactance, accounting for both inductive and capacitive effects in the circuit.

This formula ensures that both resistive and reactive properties are taken into account, providing a comprehensive measure for voltage drop.

In-Depth Formula Explanation and Variables

Every term in the voltage drop formula influences the outcome significantly. Let’s break down the variables more thoroughly.

- I_start: It is imperative to precisely estimate the startup current since it determines the magnitude of the voltage drop calculated. Inrush current can be measured or estimated from manufacturer specifications.

- R_total: Total resistance is a sum of resistances from cables, connectors, internal generator windings, and any switching devices. Environmental factors like temperature may also affect resistance.

- X (Reactance): In AC circuits, consider inductance (L) and capacitance (C). The reactance is computed as X = 2πfL for inductive components, where f represents frequency in Hertz (Hz), and similarly for capacitive components, X = 1/(2πfC).

During startup, the generator’s internal reactance is particularly significant because the system is unbalanced. Proper consideration of both resistance and reactance ensures a more reliable calculation of the voltage drop.

Comprehensive Tables for Voltage Drop Calculations

Below are extensive tables that summarize common parameters used during generator startup voltage drop calculations, including cable resistances, typical generator impedances, and examples involving system length and current.

| Cable Type | Cross-sectional Area (mm²) | Resistance (Ω/km) | Typical Temperature Rating |

|---|---|---|---|

| Copper | 4 | 4.61 | +90°C |

| Copper | 10 | 1.83 | +90°C |

| Aluminum | 16 | 1.15 | +75°C |

| Generator Type | Rated Voltage (V) | Inrush Current Factor | Typical Internal Resistance (Ω) |

|---|---|---|---|

| Small Portable | 120 | 5 – 8 times rated load | 0.2 – 0.5 |

| Industrial Standby | 240/480 | 3 – 6 times rated load | 0.05 – 0.2 |

| High Capacity Prime | 480/600 | 2 – 4 times rated load | 0.01 – 0.1 |

Step-by-Step Voltage Drop Calculation

Follow these steps when calculating voltage drop during generator startup to ensure accuracy and safety.

- Step 1: Determine the rated generator current and the expected inrush current. Use manufacturer specifications to obtain accurate figures.

- Step 2: Calculate the total resistance (R_total). Account for the cable length, cross-sectional area, conductor material, and additional resistances at connections.

- Step 3: If applicable, compute the reactance (X) using the frequency of the AC power and the inductor or capacitor properties in the circuit.

- Step 4: Apply the voltage drop formula: Voltage Drop = I_start × √(R_total² + X²). Determine if reactive components are significant for your load conditions.

- Step 5: Assess the resulting voltage drop relative to acceptable limits for generator and equipment performance. Adjust cable or system design as required.

This structured process ensures that every parameter is carefully evaluated and the computed voltage drop reliably reflects the system’s performance during startup.

Real-World Application Case Studies

To further illustrate the process, we present two common case studies showcasing voltage drop calculations for generator startups in diverse conditions.

Case Study 1: Standby Generator for an Industrial Facility

An industrial facility uses a 240V standby generator with a 300-meter copper cable run. The generator is designed for high operational reliability and faces frequent startups for power backup purposes.

- Generator Specifications:

- Rated Voltage: 240V

- Normal Operating Current: 50A

- Inrush Current Factor: 5 times rated current (approx. 250A during startup)

- Internal Generator Resistance: 0.1 Ω

- Cable Specifications:

- Cable Type: Copper

- Cross-sectional Area: 10 mm²

- Resistance: 1.83 Ω/km

- Length: 300m (0.3 km)

First, calculate the cable resistance:

Now, sum up the resistances to obtain R_total:

Assuming negligible reactance for simplicity (or that it is accounted for separately), the estimated voltage drop during startup is computed as follows:

This voltage drop indicates that during startup the potential at generators’ terminals might drop significantly, necessitating proper design considerations such as using shorter cable runs, larger cross-sectional areas, or additional compensating measures.

Case Study 2: Portable Generator in a Construction Site

A construction site uses a 120V portable generator to power tools during intermittent power outages. The generator is connected with a 50-meter aluminum cable run designed for mobility and cost efficiency.

- Generator Specifications:

- Rated Voltage: 120V

- Normal Operating Current: 15A

- Inrush Current Factor: 6 times rated current (approx. 90A during startup)

- Internal Generator Resistance: 0.3 Ω

- Cable Specifications:

- Cable Type: Aluminum

- Cross-sectional Area: 16 mm²

- Resistance: 1.15 Ω/km

- Length: 50m (0.05 km)

First, calculate the cable resistance:

Now, find the total resistance (R_total):

With an inrush current of approximately 90A, the voltage drop becomes:

Given that the generator is 120V rated, a drop of 32.18V represents approximately 26.8% of the nominal voltage. In such portable equipment, ensuring that sensitive components accommodate this drop is crucial for safe and reliable operation on the site.

Additional Considerations and Best Practices

When calculating voltage drop during generator startup, several best practices help improve accuracy and system reliability. Engineers should always incorporate safety margins and consult manufacturer guidelines.

- Regular Maintenance: Periodically check cables, connections, and generator internals to correct any deteriorating conditions that may affect resistance.

- Environmental Factors: Temperature and humidity can affect cable resistivity. Accounting for ambient temperatures may lead to adjustments in calculations.

- System Design: Evaluate cable lengths, cross-sectional areas, and material types to help mitigate excessive voltage drops. Consider paralleling cables in high-current applications.

- Advanced Modeling: In systems where reactance is significant, use comprehensive models that integrate both linear and reactive components, often requiring simulation software to capture transient behaviors accurately.

For engineers, leveraging detailed voltage drop calculations improves system efficiency during startup phases, extends equipment life, and avoids potential electrical hazards. Always verify calculations against real-world measurements and adjust simulation parameters as needed.

Frequently Asked Questions

We compiled common questions encountered during voltage drop calculations to assist further in your design and analysis.

- Q: What causes a high voltage drop during generator startup?

A: High inrush current and cumulative resistance within cables and connections are contributing factors. Upgrading cables or reducing length can decrease drops. - Q: How is reactance accounted for during AC startup calculations?

A: Reactance is computed using the inductance and frequency (and for capacitors, the capacitance) of the circuit and added to the resistance in quadrature. - Q: What are acceptable voltage drop percentages?

A: While it depends on the application, most industrial and commercial designs aim for less than 5% during normal operation; higher drops during startup might be tolerated if transient conditions are managed. - Q: How can voltage drop be minimized?

A: Use thicker cables, shorten cable runs, or employ parallel wiring. Moreover, a design review of the generator’s internal impedance can further reduce extreme drops.

Design Guidelines and Regulatory Considerations

When designing systems that include standby or portable generators, adherence to electrical standards and regulations is paramount. Regulations such as the National Electrical Code (NEC) in the United States, IEC standards internationally, and local guidelines ensure that voltage drop calculations meet safety and efficiency requirements.

- NEC Guidelines: Follow the NEC for conductor sizing, ensuring that both current-carrying capacity and resistance-based voltage drops are within acceptable limits.

- IEC Standards: Incorporate IEC standard recommendations for power generation and distribution to ensure safety, especially regarding inrush current phenomena.

- Local Codes: Local jurisdictions may have additional requirements regarding emergency power systems and generator installations that include startup voltage criteria.

Engineers should always validate their designs with updated codes and industry best practices. Also, external expert consultations can uncover system-specific issues that might not be captured in generic calculations.

Advanced Techniques and Simulation Tools

Beyond manual calculation methods, several simulation tools and software platforms can accurately model the voltage drop behavior during generator startup. These tools consider transient effects, harmonics, and other disturbances, which are especially useful for complex systems.

- Software Options: Tools like ETAP, SKM PowerTools, and MATLAB’s Simulink offer modules for transient analysis, including generator startup scenarios.

- Model Verification: Simulation outputs can be compared against physical measurements using oscilloscopes and data acquisition systems to fine-tune design parameters.

- Automation: Automated calculation and reporting tools, like the integrated AI-powered calculator mentioned earlier, further simplify the design review process.

Simulation not only supplements manual calculations but also allows for dynamic testing under varying load profiles and environmental conditions. This holistic approach enhances overall accuracy and ensures systems function as intended during every startup event.

Step-by-Step Summary and Practical Advice

For a rapid reference, follow these summarized steps when faced with generator startup voltage drop calculations:

- Determine inrush input current and generator specifications from the manufacturer.

- Measure or calculate cable resistance based on type, length, and cross-sectional area.

- Include additional resistances from connections, switches, and terminal blocks.

- Compute total impedance, integrating both resistance and reactance for AC systems.

- Apply voltage drop formulas and verify against design thresholds.

- Revise system components to mitigate excessive drops if necessary.

Following these procedural guidelines, engineers ensure reliable operation, safety, and efficiency during generator startups. The integration of simulation tools further refines the accuracy and aids early identification of potential issues.

Authoritative Resources

For further reading and detailed guidelines, consult these external authoritative resources:

- National Fire Protection Association (NFPA) – Offers guidelines on installation standards and safety codes.

- IEC Standards – Provides international standards for electrical systems and power generation.

- ETAP – A comprehensive tool for power system analysis including transient studies.

- SKM PowerTools – Software focused on electrical distribution and voltage drop analysis.

Integrating Safety and Reliability in Design

Ensuring safety and reliability in generator startup operations starts with accurate voltage drop calculations and thorough system analyses. Taking into account both theory and practical application, this article aims to equip you with the essential tools and steps necessary for robust, safe design.

- Safety Factors: Always include a safety margin when designing circuits susceptible to high inrush currents.

- Periodic Testing: Validate calculation models with real-life tests at different operational loads to safeguard against equipment failure.

- Design Reviews: Regularly review designs for compliance with evolving electrical codes and new technology standards.

- Continuous Learning: Stay updated on new techniques and tools in voltage drop analysis to ensure a forward-thinking approach in your projects.

Adopting these safety practices leads to enhanced system performance and prevents costly and hazardous downtime during critical generator startup events.

Integrating Calculations in Electrical System Design

An expertly designed electrical system accounts for every phase of operation, including the transient surge during generator startup. Detailed calculations inform decisions such as cable sizing, protective device selection, and overall system layout.

- Cable Sizing: Determine conductor sizes based on both current carrying capacity and acceptable voltage drop margins.

- Protective Devices: Use relays, fuses, and circuit breakers that can handle and protect against high startup currents.

- System Layout: Optimize generator placement relative to the load and minimize cable lengths to reduce resistive losses.

Integrating these calculations early in the design process streamlines installation and ensures that electrical networks are both efficient and resilient over their operational life cycle.

Future Trends in Voltage Drop Analysis

As electrical systems grow more complex, future trends lean toward advanced analytics and smart systems integration. Increased use of IoT sensors and real-time monitoring allows for ongoing recalibration of voltage drop calculations, adapting dynamically to load changes and environmental factors.

- Smart Sensors: IoT devices continuously monitor resistance changes and temperature variations, feeding data to optimization software.

- Data-Driven Design: Big data analysis combined with predictive modeling provides insights that refine design decisions over time.

- Energy Efficiency: Minimizing voltage drop contributes to overall energy efficiency, reducing wasted power and operational costs.

Innovations in real-time simulation and machine learning can further enhance the reliability of generator startup operations, making the system adaptive and self-correcting as conditions change.

Closing Technical Insights

In conclusion, a comprehensive understanding of voltage drop during generator startup is pivotal for ensuring the efficiency and longevity of electrical systems. This article has detailed practical formulas, in-depth tables, real-world case studies, and step-by-step instructions to achieve precise voltage drop calculations.

By integrating technical expertise with advanced simulation tools, adhering to rigorous safety standards, and following best design practices, engineers can significantly mitigate the risks related to generator startup voltage drops. Through continual learning, practical adjustments, and adherence to regulatory guidelines, the complex challenge of managing inrush currents and voltage drop is made manageable and reliably predictable.

This guide serves as a robust foundation for both new and experienced engineers in the electrical field. It provides the essential tools to analyze, design, and troubleshoot generator systems in industrial, commercial, and portable applications. Stay updated with regulatory changes, utilize high-quality simulation software, and take proactive measures in your voltage drop calculations for outstanding performance and reliability across all projects.