Mass/volume percentage (% m/v) quantifies solute mass relative to solution volume for accurate concentrations. It ensures precision in chemistry, pharmaceuticals, food industry, and laboratory applications worldwide reliably.

Mass/Volume Percentage (% m/v) Calculator

How is % m/v calculated?

What is considered a valid input?

Common Mass/Volume Percentage Values

The mass/volume percentage (% m/v) is a standard unit of concentration used to express the amount of solute in a solution. Below is a table showcasing common % m/v values and their typical applications:

| Mass of Solute (g) | Volume of Solution (mL) | % m/v (%) | Application Example |

|---|---|---|---|

| 1 | 100 | 1 | Saline solution for medical use |

| 5 | 100 | 5 | Laboratory buffer preparation |

| 10 | 500 | 2 | Glucose solution for cell culture |

| 0.9 | 100 | 0.9 | Physiological saline (normal saline) |

| 20 | 1000 | 2 | Antiseptic solution concentration |

| 15 | 750 | 2 | Pharmaceutical solution preparation |

| 50 | 1000 | 5 | Industrial cleaning solution |

| 2 | 200 | 1 | Food additive concentration |

| 25 | 500 | 5 | Laboratory reagent solution |

| 0.5 | 50 | 1 | Cosmetic product formulation |

Formulas and Detailed Explanation

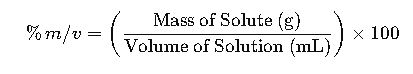

The primary formula for calculating mass/volume percentage is:

Variables:

- Mass of Solute (g): The weight of the solute dissolved in the solution, measured in grams.

- Volume of Solution (mL): The total volume of the solution, including both solute and solvent, measured in milliliters.

Common Values:

- Mass of Solute: Typically ranges from milligrams to several grams, depending on the desired concentration.

- Volume of Solution: Ranges from milliliters to liters, depending on the scale of the preparation.

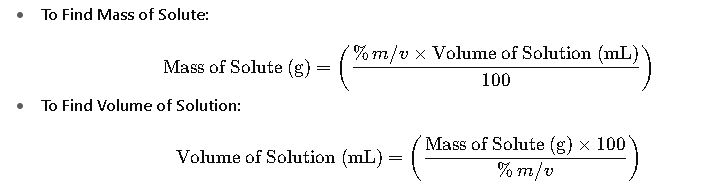

Rearranged Formulas:

Real-World Examples

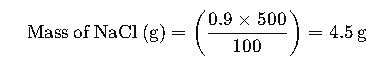

Example 1: Preparing a 0.9% m/v Saline Solution

Problem: How much NaCl is needed to prepare 500 mL of a 0.9% m/v saline solution?

Solution:

- Given: % m/v = 0.9%, Volume = 500 mL

- Using the formula:

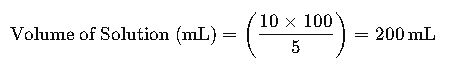

Example 2: Determining the Volume of Solution from Mass of Solute

Problem: What volume of solution is required to achieve a 5% m/v concentration with 10 g of NaCl?

Solution:

- Given: Mass of NaCl = 10 g, % m/v = 5%

- Using the formula:

Common Concentrations in Different Industries

The mass/volume percentage (% m/v) is widely used across healthcare, pharmaceuticals, food industry, and laboratories. The following table summarizes commonly encountered concentrations and their typical uses:

| % m/v | Example Solute | Typical Application | Notes |

|---|---|---|---|

| 0.9 | NaCl | Physiological saline | Used in IV drips and wound irrigation |

| 1 | Glucose | Oral rehydration solution | Mildly sweet, isotonic solution |

| 2 | Ethanol | Disinfectant solution | Standard laboratory cleaning solution |

| 5 | NaCl | Lab buffer preparation | Common in molecular biology protocols |

| 10 | Glucose | Cell culture media | Provides energy source for cells |

| 15 | Hydrogen Peroxide | Antiseptic solution | Used in low concentration for wound cleaning |

| 20 | Sucrose | Food and beverage solutions | Used in syrup and confectionery |

| 50 | NaOH | Industrial cleaning | Highly concentrated solution for heavy-duty cleaning |

This table illustrates that % m/v is versatile, allowing precise adjustment of solute concentrations for specific applications.

Factors Affecting % m/v in Practice

- Solute Type

Different solutes dissolve differently in a given solvent. Ionic compounds like NaCl dissolve readily in water, whereas larger organic molecules may require heating or special solvents. - Volume Precision

The final volume of solution is critical. Adding solute increases the total volume slightly, so measuring after dissolution ensures accuracy. - Temperature and Solubility

Temperature can affect solubility. Some compounds dissolve better at higher temperatures, while others may precipitate if the solution cools. - Application Purpose

In medical applications, accuracy is essential for patient safety. In industrial processes, small deviations might be acceptable, but they can affect efficiency.

Real-World Applications of % m/v

Case Study 1: Medical Saline Solution

A hospital needs 1 liter of 0.9% m/v NaCl solution for IV administration. This is standard “normal saline.”

Application Insights:

- Used to hydrate patients, restore electrolytes, and maintain blood volume.

- Accuracy is crucial: too much NaCl can cause hypernatremia; too little is ineffective.

- Pharmacy technicians use pre-calculated tables to weigh solutes quickly and ensure patient safety.

Case Study 2: Food Industry – Syrup Preparation

A candy manufacturer needs a 20% m/v sucrose solution to produce syrup for candies.

Application Insights:

- Ensures consistent sweetness and texture.

- % m/v helps adjust recipes for different batch sizes.

- Lab technicians often prepare small test batches to verify consistency before scaling production.

Tips for Accurate Mass/Volume Preparation

- Always use calibrated balances and volumetric flasks.

- Dissolve solute completely before adjusting the final volume.

- Label solutions with % m/v and preparation date to avoid errors.

- Document all steps for traceability in laboratory or industrial environments.

Benefits of Understanding % m/v

- Precision: Enables exact control over solution properties.

- Safety: Critical in pharmaceuticals and medical solutions.

- Efficiency: Reduces waste and ensures consistent product quality.

- Versatility: Applicable in chemistry, biology, food, and industrial processes.