Designing efficient solar energy systems requires precise battery bank capacity calculations to guarantee reliable performance. Engineers must evaluate demand, efficiency, autonomy, chemistry, depth of discharge, and temperature for accurate, sustainable storage.

Battery Bank Capacity Calculator — Solar Systems

Estimate battery amp-hours (Ah), number of batteries, and bank energy required for a solar installation (AC loads via inverter).

Which inputs matter most?

What is Depth of Discharge (DoD)?

Formulas used

Total stored energy needed (Wh) = Net usable energy / (DoD × Temperature_derate × System_efficiency).

System_efficiency = Inverter_efficiency × Battery_efficiency.

Bank capacity (Ah) = Total_stored_energy_Wh / System_voltage.

Then compute batteries in series and parallel: series = round(System_voltage / Battery_voltage), parallel = ceil(bankAh / batteryAh).

Why inverter efficiency? (AC loads)

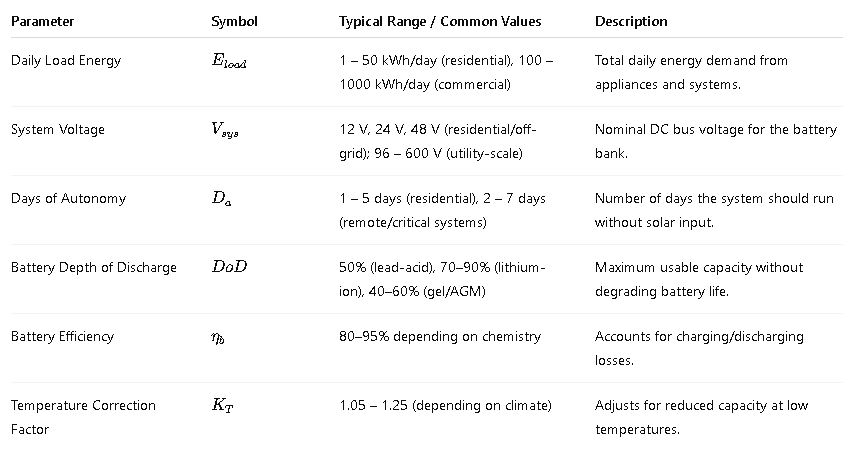

Key Parameters in Battery Bank Sizing

Before diving into calculations, it is essential to define the core variables influencing the design.

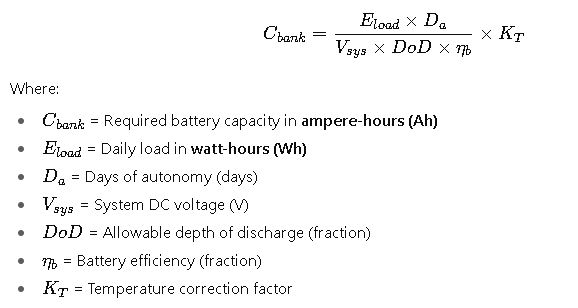

Fundamental Formulas for Battery Bank Capacity

The general equation for battery bank sizing is:

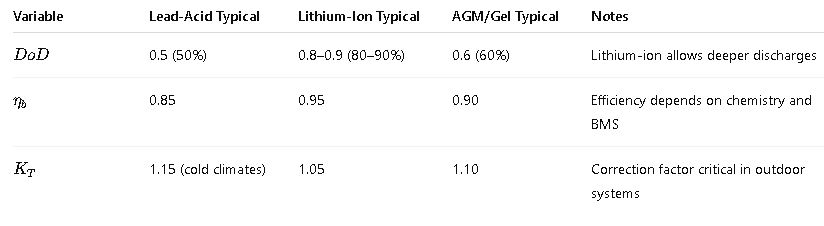

Example of Variable Values in Design

Extended Tables of Common Battery Bank Calculations

Table 1 – Required Battery Capacity (Ah) for 5 kWh/day Loads

| System Voltage | Days of Autonomy | DoD | Efficiency | Temperature Factor | Required Capacity (Ah) |

|---|---|---|---|---|---|

| 12 V | 2 | 0.5 | 0.85 | 1.1 | 1078 Ah |

| 24 V | 2 | 0.5 | 0.85 | 1.1 | 539 Ah |

| 48 V | 2 | 0.5 | 0.85 | 1.1 | 270 Ah |

| 48 V | 3 | 0.8 | 0.95 | 1.05 | 205 Ah |

| 96 V | 2 | 0.9 | 0.95 | 1.05 | 122 Ah |

Table 2 – Typical Autonomy Days for Different Applications

| Application | Recommended Autonomy (Days) | Justification |

|---|---|---|

| Residential (urban) | 1 – 2 | Grid backup or frequent sun availability |

| Off-grid cabin | 2 – 3 | Must account for cloudy days |

| Telecom towers | 3 – 5 | High reliability required |

| Remote microgrids | 4 – 7 | Long autonomy due to inaccessibility |

| Hospitals / Critical systems | 5 – 7 | No tolerance for outages |

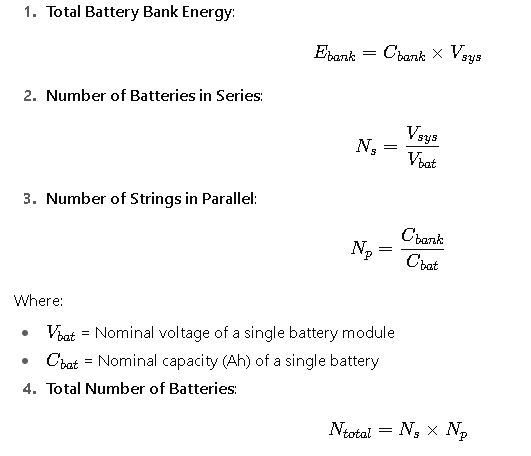

Additional Formulas for System Integration

These formulas ensure that the designed battery bank matches the electrical requirements of the PV system.

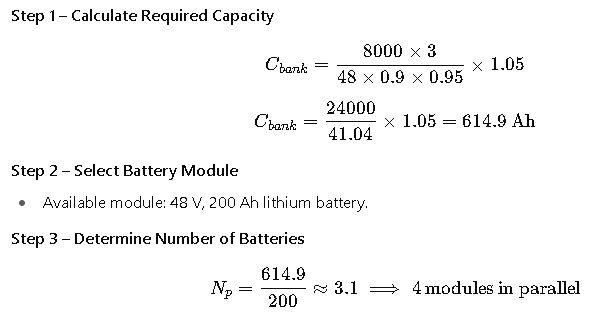

Real-World Example 1: Off-Grid Residential Cabin

Scenario:

- Daily load = 8 kWh/day

- System voltage = 48 V

- Days of autonomy = 3

- Battery type = Lithium-ion (DoD=0.9 ηb=0.95)

- Temperature factor = 1.05

Final Design:

- 4 × 48 V, 200 Ah lithium modules in parallel

- Total energy storage = 48×800=38.4 kWh

- Sufficient for 3 days of autonomy.

Real-World Example 2: Battery Bank for a Remote Telecom Tower

Scenario Description

A telecommunications company is deploying a solar-powered base station in a remote mountainous region with no grid access. The site must operate continuously with minimal maintenance. The design team estimates an average daily energy consumption of 12 kWh, primarily for communication equipment, cooling fans, and auxiliary monitoring devices.

Design Requirements

- System voltage: 48 VDC

- Days of autonomy: 5 (to cover extended cloudy periods)

- Battery type: Valve-regulated lead-acid (VRLA) due to cost considerations and proven field performance

- Allowable depth of discharge: 50%

- Battery efficiency: 85%

- Temperature correction: 1.15 (cold environment at 0–10 °C)

Engineering Analysis

The design requires a large storage reserve because communication reliability is critical. Unlike residential systems that can tolerate minor outages, telecom infrastructure must remain functional under all weather conditions. The autonomy factor of 5 days ensures service continuity even if there is no solar input for nearly a week.

Battery Module Selection

The design team selects 12 V, 250 Ah VRLA modules, which are widely available and supported in the region.

Configuration and System Layout

- Batteries are configured in series groups of four to achieve the 48 V nominal system voltage.

- Multiple parallel strings are used to achieve the necessary capacity.

- Redundant strings provide fault tolerance, ensuring that a single failure does not bring down the system.

Final Outcome

The completed system uses more than 20 batteries, providing approximately 60 kWh of storage. This ensures reliable service for five days of autonomy with proper derating for temperature effects.

This real-world case illustrates how battery chemistry, environment, and application type drastically influence capacity requirements.

Comparative Analysis of Battery Technologies for Solar Storage

Choosing the correct battery type is as critical as the capacity calculation itself. Different chemistries offer trade-offs between cost, performance, safety, and lifespan.

Table – Comparison of Common Battery Technologies in Solar Systems

| Parameter | Flooded Lead-Acid | VRLA (AGM/Gel) | Lithium-Ion (LiFePO4) | Nickel-Iron (NiFe) |

|---|---|---|---|---|

| Typical Depth of Discharge | 40–50% | 50–60% | 80–90% | 70–80% |

| Efficiency | 75–85% | 85–90% | 90–95% | 65–75% |

| Cycle Life (at 50% DoD) | 1000–1500 cycles | 1500–2000 cycles | 3000–6000 cycles | 2000–5000 cycles |

| Temperature Tolerance | Moderate | Good | Moderate | Excellent |

| Maintenance | High (water refilling, equalization) | Low | Very low (BMS-managed) | High |

| Initial Cost | Low | Medium | High | Very High |

| Common Applications | Off-grid cabins, backup | Telecom towers, rural systems | Residential, commercial, microgrids | Harsh environments, niche projects |

Insights:

- Lead-acid remains dominant in low-cost projects where budget is the priority.

- Lithium-ion is increasingly the standard due to higher efficiency and deeper discharge capability.

- Nickel-Iron, though less common, is used in extreme environments for its durability.

Design Considerations and Best Practices

1. Days of Autonomy Selection

- Urban residential projects: 1–2 days are usually sufficient since grid or generator backup is often available.

- Remote sites: At least 3–5 days are recommended, as access for refueling or repair is difficult.

- Critical infrastructure: Hospitals, data centers, and telecom towers often require 5–7 days.

2. Depth of Discharge Management

Battery longevity is strongly linked to depth of discharge. Operating lead-acid batteries beyond 50% regularly reduces lifespan drastically, while lithium-ion can safely handle up to 90%. Engineers must balance usable energy against replacement costs.

3. Temperature Effects

- Cold climates reduce capacity and efficiency, requiring larger banks.

- Hot climates accelerate degradation, especially for lead-acid systems.

- Climate-controlled enclosures or underground installations are common mitigation strategies.

4. System Voltage Optimization

- 12 V and 24 V systems: Suitable for small residential projects.

- 48 V systems: Widely used in medium-scale installations due to efficiency and reduced cable losses.

- 96 V and higher: Applied in commercial and industrial systems where large-scale storage is required.

5. Redundancy and Safety

- Parallel strings provide redundancy but must be carefully balanced to prevent unequal current distribution.

- Proper fusing, disconnects, and monitoring systems are mandatory under NEC Article 480 and IEEE 1568 guidelines.

- Battery management systems (BMS) are essential for lithium-ion installations.

Extended Table – Common Battery Bank Configurations

| Application | Daily Load (kWh) | Autonomy (Days) | Chemistry | Nominal Voltage | Typical Bank Size |

|---|---|---|---|---|---|

| Small off-grid cabin | 3 kWh | 2 | Lead-acid AGM | 24 V | 8–10 kWh |

| Urban residential backup | 6 kWh | 1 | Lithium-ion | 48 V | 7–9 kWh |

| Remote farm | 15 kWh | 3 | Flooded lead-acid | 48 V | 45–50 kWh |

| Telecom tower | 12 kWh | 5 | VRLA | 48 V | 55–65 kWh |

| Commercial microgrid | 100 kWh | 2 | Lithium-ion | 400 V | 220–250 kWh |

| Critical hospital system | 250 kWh | 5 | Lithium-ion | 600 V | 1250+ kWh |

Standards and Guidelines for Battery Sizing

- IEEE 1562 – Guide for Sizing Lead-Acid Batteries for Photovoltaic Systems.

- Provides recommended practices for calculating required capacity.

- Covers performance under varying temperatures and discharge rates.

- IEEE 1568 – Recommended Practice for Design, Installation, and Maintenance of Valve-Regulated Batteries.

- Focuses on VRLA systems in telecom and industrial applications.

- NEC Article 480 – Storage Batteries.

- Defines installation, overcurrent protection, and disconnect requirements.

- Mandates labeling, ventilation, and accessibility standards.

- IEC 61427 – Secondary Cells and Batteries for Renewable Energy Storage.

- Specifies testing and performance standards for renewable integration.

- National Renewable Energy Laboratory (NREL) Resources.

- Provides performance models, degradation data, and economic analysis tools.

- NREL Battery Resources