Reliable cable sizing ensures safety, efficiency, and regulatory compliance for electrical installations worldwide in varied.

An affordable cable sizing calculator saves time, reduces errors, and supports engineering design decisions quickly.

Cable Sizing Calculator — Affordable Tool for Conductor Cross‑Section and Voltage Drop

Why an affordable cable sizing calculator is essential for engineers and designers

An accurate cable sizing calculator is a productivity and safety enabler. Engineers must balance current carrying capacity, voltage drop, short‑circuit withstand, thermal effects, and regulatory requirements while minimizing cost and conductor size. Manual calculations are error-prone when multiple correction factors and installation modes interact. An accessible, affordable calculator that incorporates normative methodologies removes repetitive errors, enforces consistent assumptions, and documents sizing decisions for audits and site verification. Key benefits for technical teams:- Speed: rapid iteration across multiple load scenarios and installation options.

- Consistency: repeatable outputs with traceable parameter inputs and assumptions.

- Compliance: integrated normative references (IEC, NEC, BS) and automated checks (voltage drop and short-circuit).

- Cost control: optimized conductor selection reducing unnecessary copper or aluminium oversizing.

- Risk mitigation: early identification of problematic runs with high voltage drop or inadequate short-circuit capacity.

Core technical principles embedded in a robust cable sizing calculator

A professional cable sizing tool must evaluate multiple simultaneous constraints. The core equations and considerations that must be included are:Load current calculation

Single-phase resistive or general load:

Three-phase balanced loads:

Variables and typical values:

- P — Active power in watts (W). Typical: small appliances 100–5,000 W; industrial motors 5,000–500,000 W.

- V — Line voltage in volts. Typical: single-phase 230 V; three-phase 400 V (Europe); 480 V (North America industrial).

- PF — Power factor (cosφ). Typical: resistive loads 1.0; motors 0.8–0.95; electronic loads 0.6–0.95.

Current carrying capacity (ampacity)

Conductor cross-sectional area (S) must satisfy:

Requirement: Iz × diversity × correction_factors ≥ I_load

Where Iz is the tabulated current carrying capacity for the conductor, installation method, and reference ambient temperature.

Correction factors commonly applied:

- Ambient temperature factor (Ft)

- Grouping factor when multiple circuits share a containment (Fg)

- Thermal insulation or buried conditions factor (Fb)

- Renewed derating for altitude or special environments

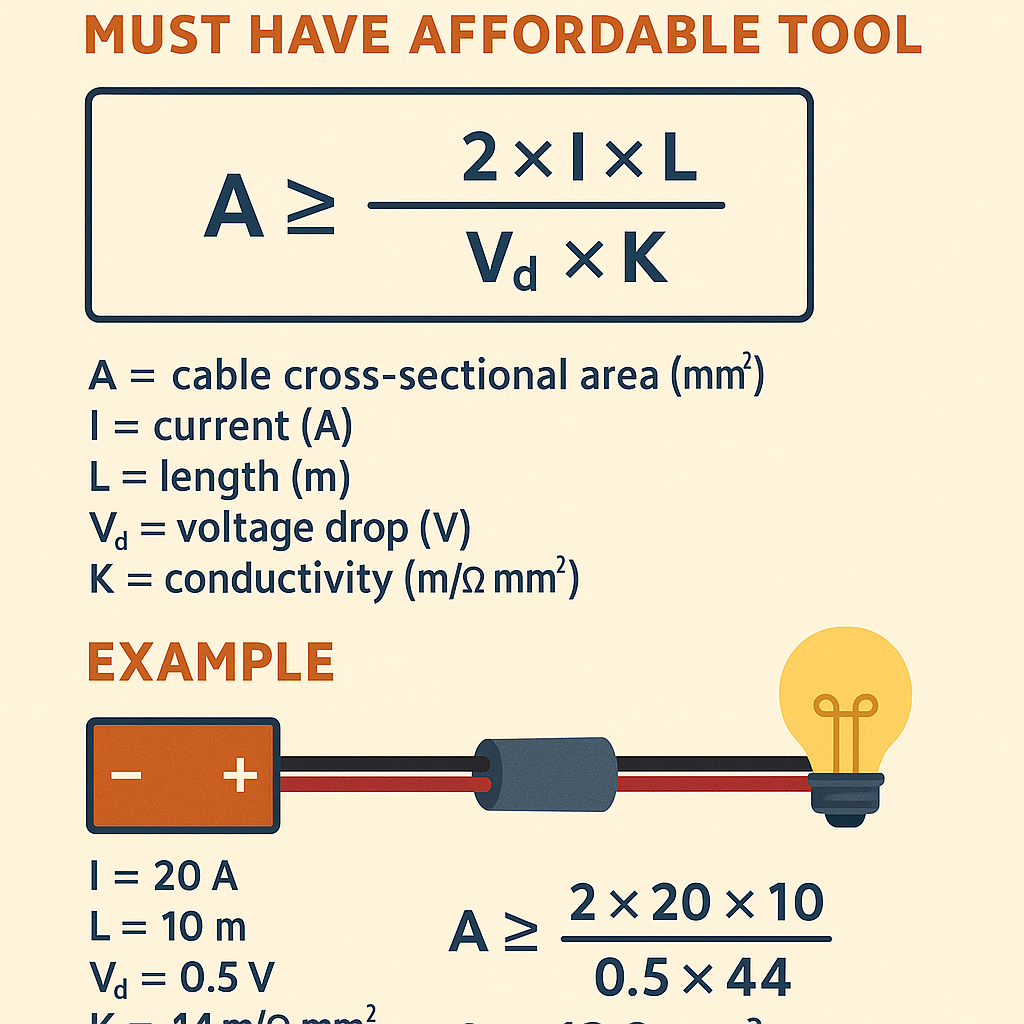

Voltage drop constraint

Voltage drop must remain within permitted limits (commonly 3% for final circuits, 5% for supply plus distribution). Use resistive and reactive contributions:

Variables and typical values:

- I — Circuit current (A).

- R — Conductor resistance per unit length (Ω/m) at operating temperature; typical copper values at 20°C.

- X — Conductor reactance per unit length (Ω/m); typical small value for short runs (e.g., 0.08–0.12 Ω/km).

- L — One-way length in meters (m).

- cosφ, sinφ — power factor components.

Short-circuit thermal check (adiabatic equation)

To ensure the conductor survives a prospective short-circuit until protection clears, use the adiabatic equation:

Variables and typical values:

- S — Conductor cross-sectional area (mm²).

- I_sc — Prospective short-circuit current (A).

- t — Protection clearing time (s). Typical: fuses 0.1–0.5 s, circuit breakers 0.03–0.5 s depending on characteristic.

- k — Material and insulation dependent constant. Typical values: copper 115–143 (depending on final permissible temperature and insulation), aluminium lower or higher depending on reference tables.

Essential normative references and authoritative links

Accurate calculators must reference and implement the methods from international and national standards:

- IEC 60364 series — Electrical installations of buildings. https://www.iec.ch/

- IEC 60287 — Electric cables — Calculation of continuous current rating. https://www.iec.ch/

- IEC 60502 / EN 50525 — Power cables with extruded insulation. https://www.cenelec.eu/

- IEC 60228 — Conductors of insulated cables (cross-sectional definitions). https://www.iec.ch/

- BS 7671 (IET Wiring Regulations) — UK guidance and tables. https://www.theiet.org/

- NFPA 70 (NEC) — US national electrical code, ampacity tables and rules. https://www.nfpa.org/

- IEEE standards and technical papers on cable modeling and harmonics. https://www.ieee.org/

Common tables embedded in the calculator

The calculator must include embedded tables for conductor DC resistance, typical reactance, and tabulated current carrying capacities for common installation methods. Example tables below provide a representative dataset for design reference. Designers must always cross-check local regulatory tables before finalizing design.

| Conductor Size (mm²) | DC Resistance at 20°C (Ω/km) Cu | Approx Reactance (Ω/km) | Typical Iz free air (A) | Typical Iz clipped direct (A) |

|---|---|---|---|---|

| 1.5 | 12.1 | 0.08 | 18 | 20 |

| 2.5 | 7.41 | 0.08 | 24 | 27 |

| 4 | 4.61 | 0.07 | 32 | 37 |

| 6 | 3.08 | 0.07 | 41 | 49 |

| 10 | 1.83 | 0.07 | 57 | 70 |

| 16 | 1.15 | 0.06 | 76 | 95 |

| 25 | 0.727 | 0.06 | 101 | 125 |

| 35 | 0.524 | 0.06 | 125 | 150 |

| 50 | 0.387 | 0.05 | 154 | 190 |

| 70 | 0.268 | 0.05 | 195 | 225 |

| 95 | 0.193 | 0.05 | 230 | 275 |

| 120 | 0.153 | 0.04 | 260 | 315 |

| 150 | 0.124 | 0.04 | 290 | 355 |

| 185 | 0.100 | 0.04 | 320 | 395 |

| 240 | 0.075 | 0.03 | 370 | 460 |

| Ambient Temp (°C) | Correction Factor Ft (PVC) | Correction Factor Ft (XLPE) |

|---|---|---|

| 20 | 1.08 | 1.10 |

| 25 | 1.00 | 1.03 |

| 30 | 0.91 | 0.95 |

| 35 | 0.82 | 0.87 |

| 40 | 0.71 | 0.78 |

| 50 | 0.58 | 0.67 |

Implementation features a professional calculator must include

A practical, affordable tool should implement the following capabilities:- Load type selection: single-phase, three-phase, motors with starting currents, harmonic-rich loads.

- Automatic selection of conductor material: copper or aluminium with appropriate ampacity and resistance tables.

- Installation method library: enclosed conduit, buried, clipped direct, on-tray, multi-core, each altering Iz.

- Correction factor engine: ambient, grouping, soil thermal resistivity, insulation, and altitude effects.

- Voltage drop calculator: include resistive/reactive contributions, per-phase and percent drop limits; automatic iteration to next standard conductor size.

- Short-circuit adiabatic check: compute prospective fault currents and verify conductor thermal integrity with user-defined protection clearing times.

- Harmonics and derating: capability to apply K-factor or derating for non-sinusoidal current waveforms where necessary.

- Exportable reports: traceable inputs, calculations, normative references, and final recommended cable sizes for procurement or approval.

Example 1 — Single-phase water heater circuit (complete development)

Scenario: A domestic single-phase 230 V water heater rated 5 kW located 20 m from the distribution board. Acceptable voltage drop ≤ 3% (6.9 V). Copper conductor, PVC insulated, clipped direct in conduit in a loft at ambient 30°C. Diversity not applicable. Protection: 32 A MCB with short-circuit clearing time 0.1 s. Determine minimum cable size satisfying current carrying capacity, voltage drop, and short-circuit withstand.

Step 1 — Calculate load current:Assume PF = 1 (resistive heater).

From table, Ft for PVC at 30°C = 0.91. Iz required = I / Ft = 21.74 / 0.91 = 23.89 A

Select standard conductor size where tabulated Iz ≥ Iz required. From table above, 2.5 mm² Iz ~24 A (free air) and 4 mm² Iz ~32 A. Considering clipped direct Iz higher; conservative choice is 2.5 mm² if permitted installation method Iz ≥ 24 A.

Step 3 — Voltage drop check:From table R for 2.5 mm² Cu = 7.41 Ω/km = 0.00741 Ω/m.

Percent drop = (6.44 / 230) × 100% = 2.8% <= 3% allowable → acceptable.

Step 4 — Short-circuit adiabatic check:Prospective short-circuit current near origin (assume 6 kA prospective) and breaker clearing time t = 0.1 s. Use conservative k for copper = 115.

Required S = (I_sc × √t) / k = (6,000 × √0.1) / 115 = (6,000 × 0.3162) / 115 = 1,897 / 115 = 16.5 mm²

This suggests that under such a high local prospective short-circuit current and 0.1 s clearing, 2.5 mm² is inadequate to meet adiabatic criterion at the assumed I_sc. However, realistic prospective I_sc must be calculated from system short-circuit studies; if I_sc is lower (for example 1 kA), S requirement reduces: (1,000 × 0.3162)/115 = 2.75 mm².

Final recommendation:- If local prospective short-circuit current is <≈1.0 kA, 2.5 mm² Cu is acceptable for ampacity and voltage drop.

- If prospective I_sc is high near origin (several kA), increase size to 10–16 mm² or ensure protection with faster clearing devices or use a cable with higher k constant or specific short-circuit rated conductors.

Example 2 — Three-phase motor feeder (complete development)

Scenario: Industrial 50 kW, 400 V, three-phase motor, PF = 0.9, efficiency 92%, cable run length 50 m one-way, installation in cable tray with three cores, ambient temperature 35°C, group contains 3 similar feeders in the tray, permissible voltage drop 5%. Copper conductor, XLPE insulation. Short-circuit prospective current at the origin 10 kA. Motor starting current and thermal withstand are considered separately.

Step 1 — Continuous full-load current:Ft for XLPE at 35°C = 0.87 (from table). Grouping factor Fg for 3 current-carrying conductors in a tray (typical) ~0.8 (use normative table per standard).

Effective Iz required = I / (Ft × Fg) = 87.2 / (0.87 × 0.8) = 87.2 / 0.696 = 125.3 A

Step 3 — Select standard conductor size:From table: 25 mm² Iz ~101 A, 35 mm² Iz ~125 A, 50 mm² Iz ~154 A. To meet 125.3 A choose 50 mm² to provide margin, or 35 mm² if exact match per manufacturer Iz for installation method gives slightly higher Iz. Conservative selection: 50 mm² Cu.

Step 4 — Voltage drop check:Need conductor resistance R for 50 mm² from table: R = 0.387 Ω/km = 0.000387 Ω/m. Reactance X approximate 0.05 Ω/km = 0.00005 Ω/m.

ΔV = 1.732 × 87.2 × 0.0003701 × 50 = 1.732 × 87.2 × 0.018505 = 1.732 × 1.616 ≈ 2.799 V

Percent drop = (2.799 / 400) × 100% = 0.70% << 5% acceptable.

Step 5 — Short-circuit adiabatic check:Use S = (I_sc × √t) / k with assumed k = 115 for copper and protection clearing time t. For a motor feeder, upstream breaker clearing time for a significant fault may be 0.2 s.

S_required = (10,000 × √0.2) / 115 = (10,000 × 0.4472) / 115 = 4472 / 115 = 38.9 mm²

Chosen 50 mm² satisfies adiabatic requirement. If faster protection or lower I_sc exists, a smaller conductor could suffice.

Final recommendation:- 50 mm² copper XLPE in tray with three cores provides ampacity margin, meets voltage drop and withstands prospective short-circuit of 10 kA with 0.2 s clearing.

- Document assumptions: grouping factor 0.8, Ft 0.87, prospective I_sc 10 kA, breaker clearing 0.2 s.

Practical UX and output expectations for a calculator interface

A usable affordable tool should present:- Input panel: load type, power, voltage, PF, efficiency, number of phases, length, installation method, ambient temperature, grouping count, conductor material, insulation type, max allowable voltage drop, and prospective short-circuit current.

- Automated iteration: step through candidate conductor sizes and present pass/fail for ampacity, voltage drop, and short-circuit checks across candidates.

- Clear results: recommended conductor size(s), percent voltage drop, tabulated correction factors used, and normative references for each step.

- Exportable PDF with all calculations and references for approvals and procurement.

Quality assurance, validation, and regulatory traceability

To be trusted in professional practice, the calculator must:- Implement and log normative table versions (e.g., IEC 60287 edition, BS 7671 edition, NEC table reference) so auditors can verify assumptions.

- Allow expert override of correction factors with justification comments.

- Be validated against benchmark examples from standards or trusted handbooks and include test suites for edge cases (high ambient, multi-tier grouping, long runs).

- Provide uncertainty or sensitivity analysis: how results change with ±10% variations in key inputs (ambient temp, PF, length).

Common pitfalls and mitigation strategies

- Underestimating ambient effects: always use local ambient and solar gain assumptions for exposed cables.

- Ignoring grouping: bundling many circuits in a single tray can drastically reduce Iz; always apply grouping factors and consider alternative routing or spacing.

- Using DC resistance at 20°C without temperature correction: conductor resistance rises with temperature—use appropriate operating temperature corrections for long loaded runs.

- Neglecting harmonics: non-sinusoidal currents can increase heating; apply K-factor methods or derating where applicable.

- Short-circuit assumptions: derive prospective I_sc from system study rather than conservative blanket assumptions to avoid unnecessary oversizing.

How to select an affordable yet professional calculator

Consider these criteria:- Standards compliance: implements IEC/NEC/BS normative algorithms and references.

- Transparency: shows intermediate steps and the tables used for each calculation.

- Configurability: adjustable correction factors, installation methods, and protective device characteristics.

- Extensive database: conductor resistances, reactance values, tabulated Iz for multiple installation methods.

- Reporting and traceability: exportable calculation sheets with normative citations and a change log.

- Validation: contains unit tests against published examples and allows user verification.

Further reading and authoritative sources

To deepen technical understanding and ensure compliance consult the primary normative documents and technical handbooks:

- IEC 60287 series — Calculation of the current rating of cables: https://www.iec.ch/

- IEC 60364 — Electrical installations of buildings: https://www.iec.ch/

- BS 7671 (IET Wiring Regulations) — Practical rules and appendices: https://www.theiet.org/

- NFPA 70 (National Electrical Code) — Ampacity tables and grounding rules: https://www.nfpa.org/

- IEEE papers and cable technical guides — conductor impedance and harmonic effects: https://www.ieee.org/

- CENELEC and EN 50525 — cable product standards and guidance: https://www.cenelec.eu/