With this tool you will know what is the equivalence of AWG (North American dimensions) to mm² (European dimensions) for cables and electrical conductors.

In reality there is no exact correspondence between these two types of measurement since the specifications of both systems differ in terms of specification and resistance, however with the following application you can have a very good reference.

Definitions of AWG and mm²

Commonly electrical cables and conductors are expressed in two AWG standards – American Wire Guage (American) and mm² (European).

AWG – American Wire Gauge.

It is an American standard for the size of conductors and cables. The “gauge” is related to the diameter of the cable.

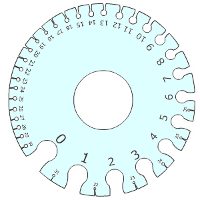

At larger numbers, smaller diameters, for example a No 8 AWG has a smaller diameter than a No 2 AWG, this can be clearly seen in the following image:

The AWG standard includes copper, aluminum, and other wire materials. Typical household copper wiring is AWG number 12 or 14. Telephone wire is usually 22, 24, or 26. The larger the gauge number, the smaller the diameter and the thinner the wire.

Since the thicker cable carries more current because it has less electrical resistance over a given length, the thicker cable is better for longer distances. For this reason, where extended distance is critical, a utility that installs a network may prefer a thicker, smaller AWG gauge electrical cord, for example a No 4 AWG rather than a No 8AWG.

How AWG dimensions are calculated.

In the American Wire Gauge (AWG) system, wire size diameters can be calculated by applying the formula D (AWG) = .005 × 92 ((36-AWG) / 39) inch. For measures 1/0, 2/0, 3/0, etc., use -1, -2, -3, which makes more mathematical sense than “double anything.”

This means that in the American wire gauge each 6-gauge decrease doubles the diameter of the wire, and each 3-gauge decrease doubles the cross-sectional area of the wire. Similar to dB in signal and power levels. An approximate but precise enough form of this formula provided by Mario Rodríguez is D = .460 * (57/64) (awg +3) or D = .460 * (0.890625) (awg +3)

AWG is sometimes known as Brown and Sharpe Wire Gauge (B&S).

Important note!

The diameter of a solid and stranded wire with the same AWG is not identical. The diameter of a braided cable is greater than the diameter of a solid cable.

Kcmil definition

In the North American electrical industry, conductors greater than 4/0 AWG are generally identified by area in thousands of circular thousandths (kcmil), where 1 kcmil = 0.5067 mm².

A circular millimeter is the area of a wire one millimeter in diameter. One million circular thousandths is the area of a rod 1,000,000 = 1 inch in diameter.

Definition mm²

This is the metric definition of cables in Europe, wire and cable sizes are expressed in cross-sectional area in mm² and also as the number of wire strands of a diameter expressed in mm.

For example, 7 / 0.2 means 7 strands of wire every 0.2mm in diameter. This example has a cross sectional area of 0.22 mm².

AWG and mm² standards

AWG (norma ASTM B 258)

The American Wire Gauge (AWG), also known as the Brown & Sharpe Wire Gauge, is a logarithmic staggered standardized wire gauge system used since 1857, predominantly in North America, for round, solid, non-wire diameters. ferrous and electrically conductive.

The dimensions of the cables are given in ASTM B 258. The cross-sectional area of each meter is an important factor in determining its current carrying ampacity.

mm² (standard IEC 60228)

It is the International Electrotechnical Commission or international standard on the conductors of insulated cables. The current version is the Third Edition 2004-11. Among other things, it defines a set of standard cross-sectional areas for cables.

This International Standard specifies nominal cross-sectional areas, in the range of 0.5mm 2 to 2,500mm 2, for conductors in power cables and wires of a wide range of types. Also included are requirements for wire numbers and sizes, and resistance values. These conductors include solid and stranded copper, aluminum, and aluminum alloy conductors in cables for fixed installations and flexible copper conductors.

In engineering applications, it is often more convenient to describe a cable in terms of its cross-sectional area, rather than its diameter, because the cross-section is directly proportional to its strength and weight, and inversely proportional to its strength. The cross sectional area is also related to the maximum current that a cable can safely carry.

Examples of using the AWG to mm² conversion tool